CORT MAGNETS——about us

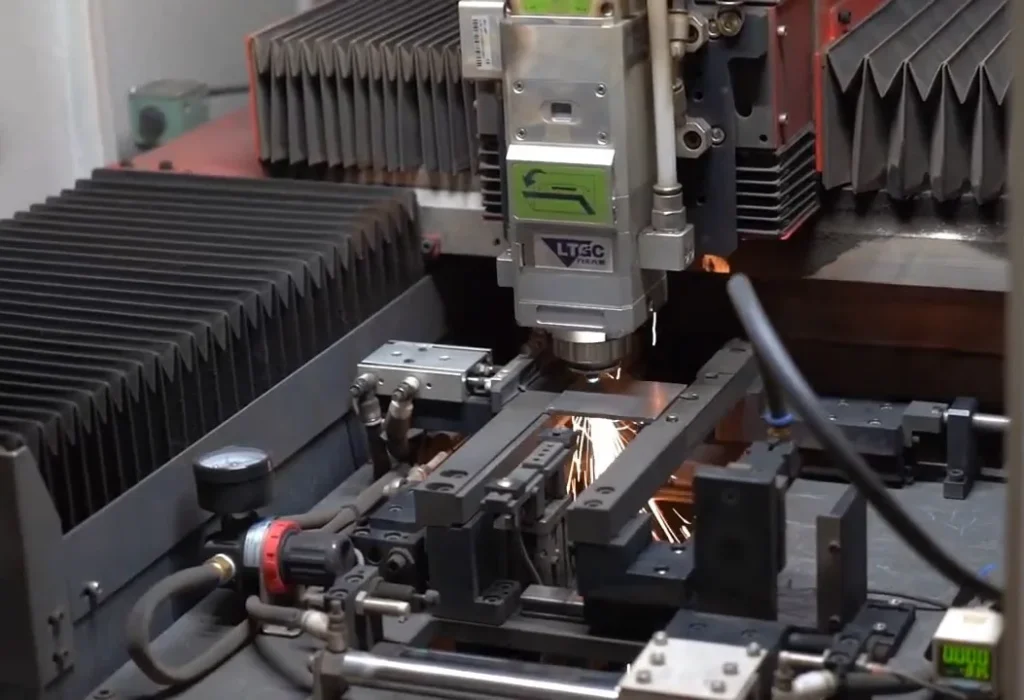

CORT MAGNETS is magnetic material manufacturer, was established in 2010, the company is located in Zhejiang province Hangzhou City, current plant area of 20000 square meters, with over 1000 skilled employees, it currently has an annual production capacity of 2000 tons and a complete end-to-end production line, with more than 250 sets of automatic slicing machine, 50 sets of multi-line machines and various shape processing machines.

CORT MAGNETS has consistently passed the IS09001, IATF 16949, and ISO14001 quality management system certifications issued by SGS for many consecutive years, and products comply with the requirements of the ROHS directive.

The surface treatment technology of the products is excellent, the substrate is directly plated with copper or chemical nickel, which makes the plating layer and the substrate indivisible and thus reduces the influence of the plating layer on the magnetism, and it has excellent resistance to corrosion, and new adhesive super glue.

Magnetizm grade from N35, N38, N40, N42, N45, N48, N50, and N52, including temperature resistance level M-H-SH-UH-EH, etc. Disc, block, ring, rod, countersunk, Magsafe ring, Magsafe magnet, pot, custom(arc, trapezoidal, hexagon, etc), and ceramic magnets, high-temperature resistant strong magnet.

The products are widely used in consumer electronics, new energy vehicles, energy-saving motors, wind power generation, high-end audio, and other fields.

Business idea

our vision

about us

Quality products

CORT is a magnetic material manufacturer, we provide solutions for customers.

custom branding

We offer OEM/ODM services to meet your specific requirements. Whether you need magnets in common shapes, different materials and grades, various sizes or surface coatings, we can meet your needs.

competitive price

Cort has over 15 years of industry experience, we provide professional technical support and robust after-sales service. Our price is very competitive, you will get the best value for your money.

Factory inspection equipment

Display of some factory inspection equipment of CORT MAGNETS

KEYENCEVR-5000-3D contourdetector

Measuring the shape and roughness of the product, from the whole to the local details, can be done with one device, which offers a measurement range that is five times greater than previous models. It also features an "automatic processing and setting function" designed to eliminate human measurement errors.

Zeiss3DMeasuring

High-density scanning points provide measurement results that are highly reliable and repeatable. The probe connection method and length range are widely applicable, while the use of ceramic parts and a long bearing seat ensures accuracy and reproducibility. Additionally, the compact base and backpack control cabinet help save space.

MAGCAM3DMagnetic FieldScanner

Using a 128x128 matrix array of Hall probes, surface scanning of magnetic steel quickly reveals the magnetic distribution of its surface. The software is developed in Python, providing analysis results that are more intuitive and convenient.

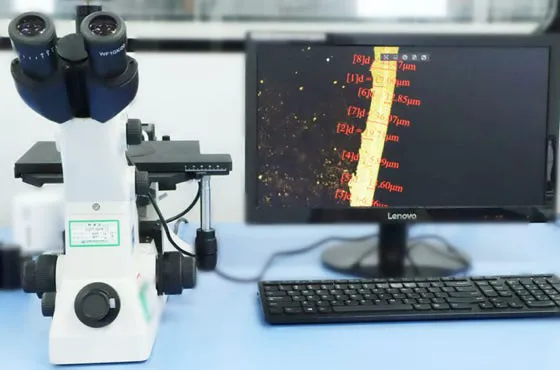

Invertedmetallurgical microscope

Equipped with large-field eyepieces and long-glass, this device offers a large and clear field of view. It features locking distance achromatic objectives without a cover, a limiting device for coarse movement tightness, a fine movement scale value, and a halogen lamp for observation and polarized light adjustment.

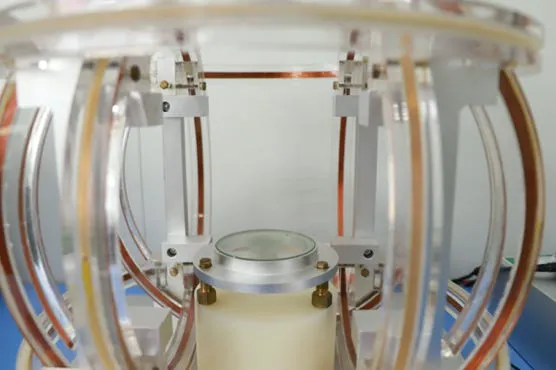

Magneticdeclination detection

The three-dimensional Helmholtz coil is a magnet placed on the sample stage. The magnetic flux value, magnetic moment, and angles of the three components can be measured using a connected three-component fluxmeter and special software. This software can display the measurement data and perform statistical analysis. It simultaneously shows MX, MY, MZ, M, and the magnetic declination angle (α).

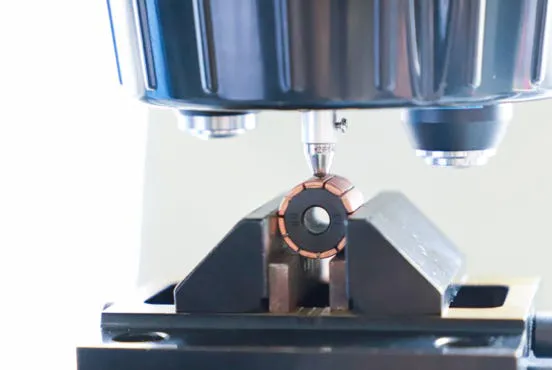

MitutoyoRockwell HardnessTester

Mitutoyo Rockwell Hardness Tester generates multiple Rockwell, Rockwell surface, and Brinell hardness test force levels. Its dolphin-nosed indenter measuring arm design is convenient for both inner and outer contact. Real-time electronic force measurement control ensures high-precision load and effectively avoids test force overload.

ICPcomposition analyzer

This system performs semi-quantitative and quantitative analysis of major, trace, and ultra-trace elements in samples. It includes a solid detector and comprises several key components: a sampling system, a high-frequency system, a detector, analysis software, a generator, a plasma torch, and an optical path computer system. The computer controls the instrument, monitors its performance, and automatically adjusts the parameters for optimal operation.

3Dmagneticfield scanner

The system consists of a high-precision Hall probe, a multi-dimensional numerical control micro-motion platform, a controller, a high-resolution electric rotating table, and control acquisition software. This setup is capable of testing the characteristics of both static and dynamic magnetic field distribution in products and can generate various visual representations.

CORT——one-stop magnetic material solutions.

As one of the leading manufacturers of magnetic materials in the world, we offer a comprehensive range of magnetic products.