Customizable N52 Neodymium Magnets Solution丨CORT

Material: Permanent Neodymium Magnet

MOQ: 100 pcs

Shape: Circular magnet

Grade: N52/Customize

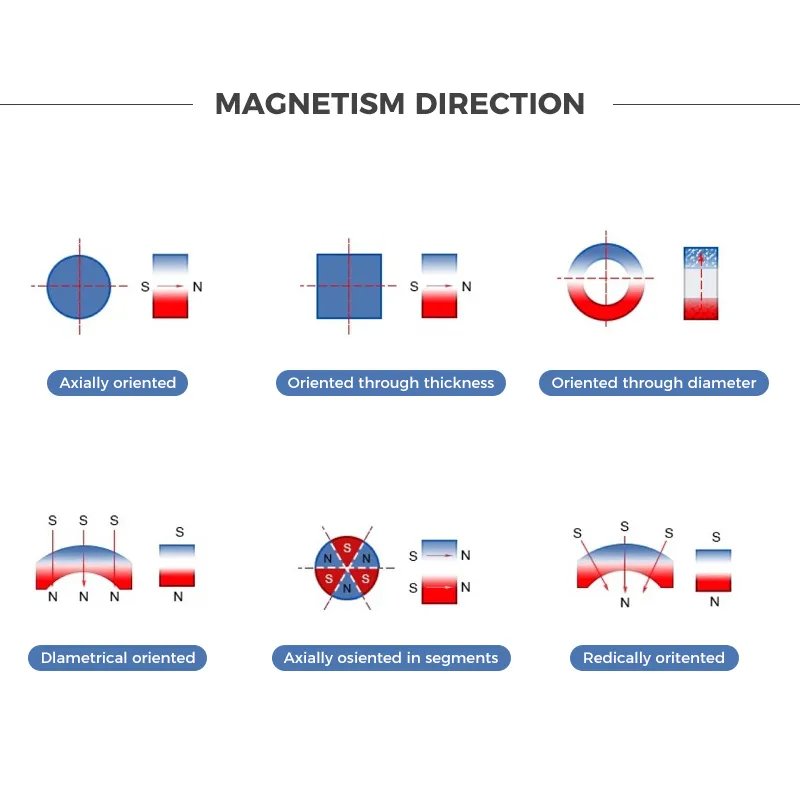

Magnetic Direction: Axial Magnetized

Coating: Nickel

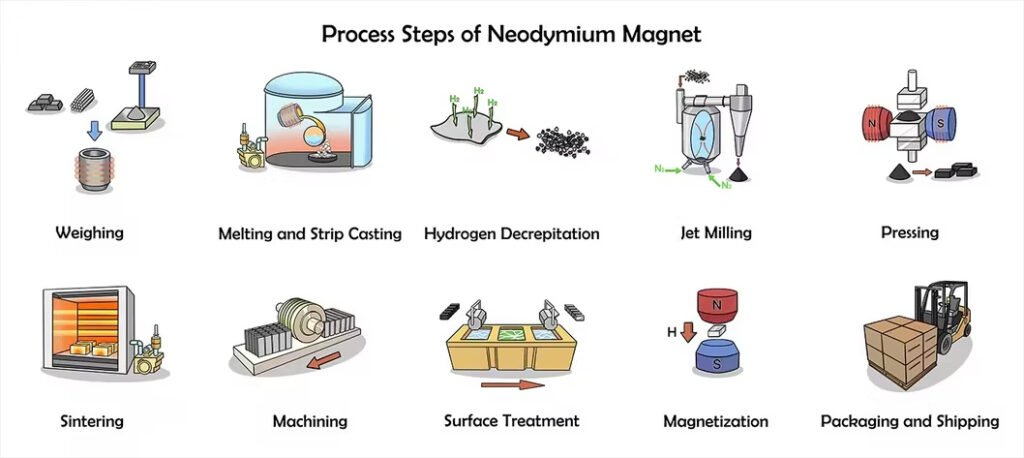

Processing: Sintered Magnet

Tolerance: +/-0.05mm

N52 Neodymium Magnets Product Overview

CORT’s Customizable N52 Neodymium Magnets are a standout in the high-performance magnetic material field. As a member of the NdFeB family, the 3rd generation rare earth permanent magnet, N52 neodymium magnets have outstanding magnetic properties. They are the ideal choice for many applications that require high performance, miniaturization, and lightweight solutions, especially for B-end clients’ diverse needs and large-scale procurement.

N52 Neodymium Magnets Core Materials and Characteristics

- Material and Neodymium magnet grades: Permanent Neodymium Magnet with N52 grade, belong to neodymium iron boron magnets (NdFeB) permanent magnet series. High remanence, high coercivity and high magnetic energy product, can generate strong magnetism in small volume, excellent performance in many application scenarios. For example, compared with lower grade magnets, N52 neodymium magnets can provide much stronger attraction force in the same size, suitable for applications that require high magnetic strength.

- Magnetic Direction: Axial Magnetized, the magnetic field direction is along the axial direction of the magnet. This feature is precise solution for applications that require specific magnetic field orientation. In devices such as motors and sensors, the axial magnetization can work better with other components, to achieve efficient energy conversion or signal detection.

- Coating: Nickel coating. Neodymium-iron-boron magnets are prone to corrosion due to reaction with oxygen, the nickel coating can isolate the magnet from the outside environment, improve corrosion resistance and extend service life. In high humidity or corrosive gas environment, the nickel coating can protect the magnet and keep its magnetic performance stable.

- Shape and Processing: Circular magnet, Sintered Magnet process. Sintering process can maximize the magnetic properties of the magnet and ensure high density and mechanical strength. Circular design is suitable for applications that involve rotation or circular motion, such as motor rotors and magnetic couplings.* Tolerance: +/-0.05mm

N52 Neodymium Magnets Customization Options

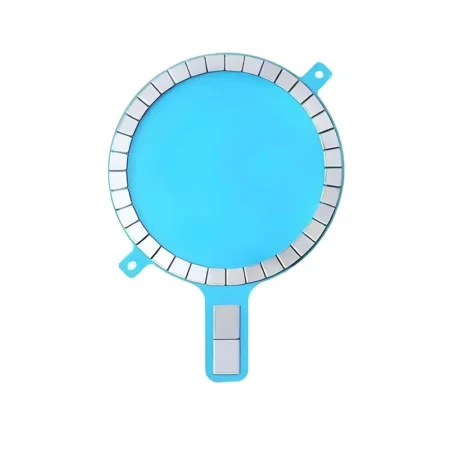

- Shape Customization: Besides the standard circular shape, we can also customize the shape into various special shapes like rings, squares, and irregular forms to meet the installation and usage requirements of different devices and application scenarios. For example, custom-shaped magnets can be tailored to fit the internal space of some uniquely designed electronic devices or create magnet products with a unique appearance according to customers’ design concept.

- Performance Customization: Based on customers’ application requirements, we can fine-tune the magnetic properties within a certain range, such as adjusting the remanence and coercivity to meet different working environments and device performance requirements. For medical devices or scientific research instruments that have specific requirements for magnetic field strength, we can customize the magnetic properties to meet their precise operational needs.

- Coating Customization: Besides the existing nickel coating, we can also customize different coating materials and treatment processes like galvanization, epoxy coating, and Parylene coating according to the usage environment and special requirements. This enhances the protection in a specific environment and meets customers’ diverse usage scenarios.

Wholesale Benefits

- Supply Capacity: Equipped with advanced and comprehensive production facilities and an efficient production process, we have strong mass production capacity. Whether it’s for B-end customers or small orders, we can ensure a timely, stable, and sufficient supply to meet both urgent needs and long-term cooperation requirements.

- Cost-effective: Through optimized supply chain management, centralized raw material procurement, and adoption of advanced production technology to reduce energy consumption, we control the production cost. For B-end customers who purchase in bulk, we can offer a competitive price to help them reduce procurement costs and increase profit margin.

- Quality Control: We have established a strict and comprehensive quality control system that covers every process from raw material inspection and screening, multi-process detection during production, to final quality acceptance of the finished products. Each neodymium magnet undergoes professional magnetic performance testing, appearance inspection, and dimensional measurement to ensure stable and reliable product quality so customers can buy with confidence.

Application Scenes

- Consumer Electronics: Applied in components like wireless charging modules, speakers, vibration motors, and sensors of consumer electronics products like mobile phones, computers, and tablets. In a wireless charging module, for example, the strong magnetism of N52 neodymium magnets can ensure precise magnetic positioning between the device and the charger, improve charging efficiency, and stability. In speakers, their high magnetic energy product can enhance sound quality, making the sound clearer and fuller.

- Industrial Neodymium Magnets: Used in motors, solenoid valves, magnetic fixtures, and automated transmission equipment. In motors, N52 neodymium magnets can increase the power density and efficiency of the motor, miniaturize it, and enable high-performance operation. In magnetic fixtures, their strong attractive force can hold workpieces firmly, ensuring the accuracy and stability of the machining process.

- Industrial Automation: Used in motors, solenoid valves, magnetic fixtures, and automated transmission equipment. In motors, N52 neodymium magnets can increase the power density and efficiency of the motor, enabling miniaturization and high performance. In magnetic fixtures, their strong attractive force can hold workpieces firmly, ensuring the accuracy and stability of the processing.

- Medical Equipment Industry: Plays a key role in medical products such as magnetic resonance imaging (MRI) devices, medical sensors, drug delivery systems, and rehabilitation physiotherapy equipment. In MRI devices, N52 neodymium magnets can generate a stable and strong magnetic field, the basis for high-resolution imaging. In medical sensors, their magnetic properties are used to achieve accurate detection of human physiological parameters.

- Aerospace Field: Suitable for aviation instruments, satellite communication equipment, and aircraft attitude control systems. In aviation instruments, the high stability and strong magnetism of N52 neodymium magnets ensure the instrument works accurately in the complex flight environment. In satellite communication equipment, they can be used to manufacture high-performance microwave devices, improve the efficiency and quality of signal transmission.

- New Energy Vehicle Industry: Has important applications in components such as drive motors, battery management systems, and wireless charging systems of electric vehicles. In drive motors, N52 neodymium magnets can increase the torque and efficiency of the motor and extend the vehicle’s range. In battery management systems, they can be used in magnetic sensors to monitor the state parameters of the battery.

Installation and Maintenance

- Installation: During the installation process, avoid violent collision and improper attraction between magnets to prevent damage to the magnets or injury to personnel. For large or specially customized shape magnets, professional installation tools and equipment may be required. Also, ensure the installation surface is clean and flat to ensure the magnet can be installed firmly and accurately. We can provide customers with detailed installation guides and professional technical support, and send technicians to the site for guidance if necessary.

- Maintenance: In daily use, keep magnets away from strong acids, alkalis, strong oxidants, and other corrosive substances to prevent coating damage and magnet corrosion. Wipe the surface of the magnet with a clean and soft cloth regularly. If the magnet is not used for a long time, store it in a dry, cool place without strong magnetic field interference, and do not pile it with other magnetic substances to prevent magnetic decline or magnetic field disorder.

N52 Neodymium Magnets Product Features

- High Performance: N52 neodymium magnets are one of the most powerful permanent magnets available, with high remanence, high coercivity, and high magnetic energy product, meeting the strict magnetic requirement of many high-end and precision applications.

- Customizable: We offer full customization service, including shape, performance, and coating, to meet the diverse and personalized needs of different B-end customers and support customers’ product innovation and differentiation.If you need custom neodymium magnets, you can contact us and we will provide you with a professional one-stop customized solution.

- Wide Application: Suitable for many industries, including electronics, industry, medical, aerospace, and new energy vehicles, with broad market application prospects, and can provide magnetic solutions for customers in different industries.

- Reliable Quality: A Strict quality control system and advanced production process ensure stable and reliable product quality, high consistency of magnetic properties, and good long-term performance.

Frequently Asked Questions—N52 Neodymium Magnets

1. What’s the sample and mass production lead time?

Sample lead time is 2-5 days, mass production lead time is 15-25 days. But it depends on the complexity of the order (e.g., the customization requirement) and our production schedule. We will confirm the exact lead time with you after receiving the order to make sure it meets your time requirement.

2.What is information we need before quotation for NdfeB magnet?

Before our quotation, we usually need the following information.

The grade of Magnet and size, and coating requirement.

3.How can I get a sample to check your quality?

After price confirmation, you can require for samples to check our quality. If you just need a stock sample to check the quality, we will provide you sample for free, as long as you afford the express freight.

4.What is your terms of payment?

Normally 50% deposit, and 50% payment before shipment. Because all of magnets are custom made.

5.How fast can I get a reply?

You will receive our reply within 15 minutes during our work time 08:00 – 18:00(UTC-8).

6.What is NdFeB Magnets?

When I ask myself, “What is NdFeB magnets?” I think of neodymium-iron-boron magnets. People also call them neodymium or NdFeB magnets. These magnets combine neodymium, iron, and boron, creating the strongest rare-earth magnets available today. Their unique crystal structure, known as Nd2Fe14B, enables them to generate powerful magnetic fields.