Customized Samarium Cobalt Magnets for Various Applications丨CORT

Customized Service:OEM&ODM

MOQ:100 PCS

Material:Support customization

Material grade:Support customization

Magnet shape:Support customization

Size:Customized

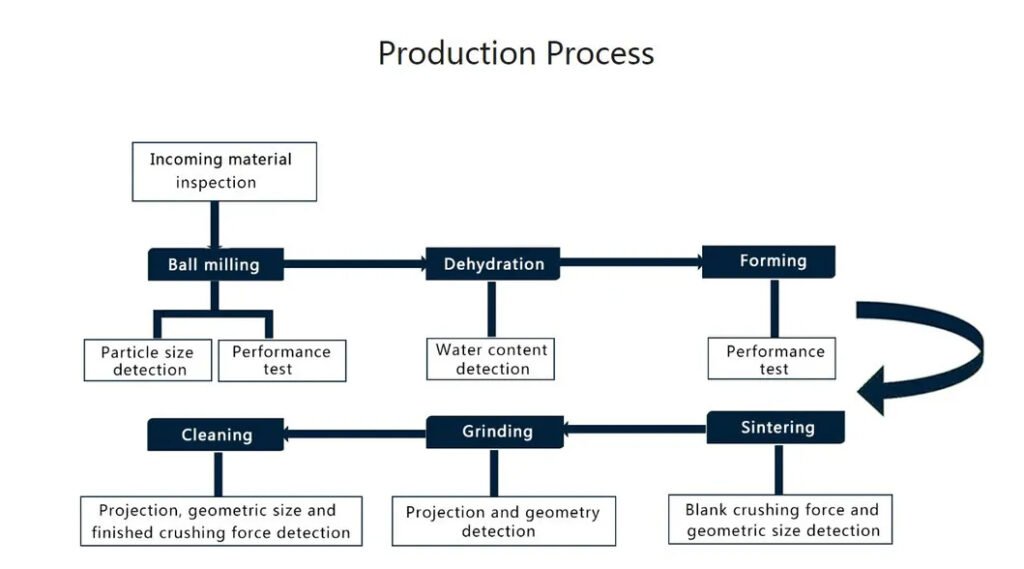

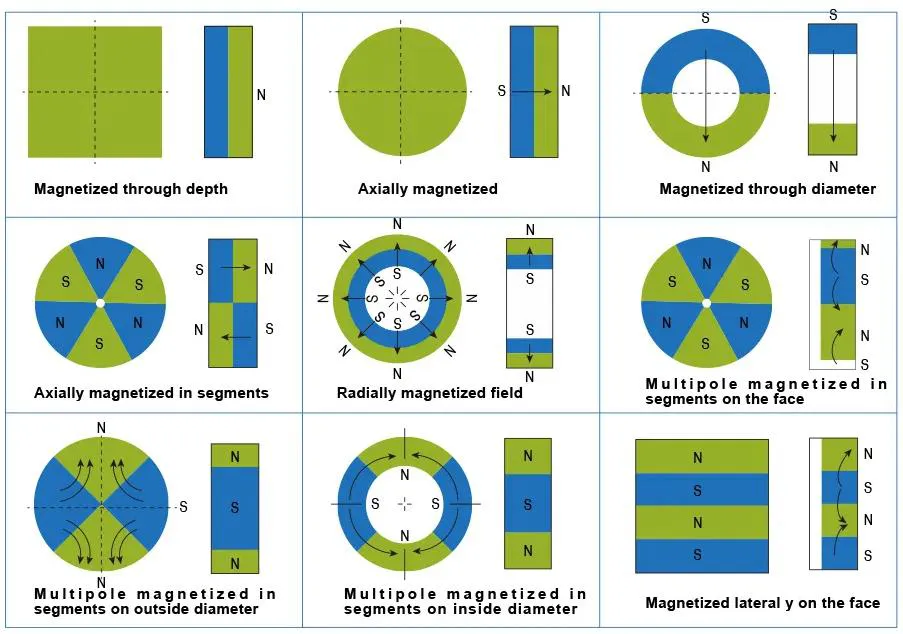

Magnetization direction:Support customization

Samarium Cobalt Magnets Product Overview

CORT’s Customized Samarium Cobalt Magnets for Various Applications are the magnetic components to meet your needs across multiple industries. Samarium cobalt magnets are known for their great properties and are used in applications that require high performance magnetic solutions.

Samarium Cobalt Magnets Core Materials and Features

- Material Composition: SmCo (samarium cobalt) is the material used to make these magnets. SmCo has extremely high magnetic properties, high thermal stability, and excellent corrosion resistance.

- Shape: Disc. This disc shape is beneficial in applications where a flat circular magnetic structure is required, such as in some motor and speaker designs.

- Type: Permanent SmCo Micro Magnets. “Permanent” means they don’t need an external power source, and “micro” means they are suitable for applications where space is limited.

- Coating: Nickel. Nickel plating can improve the magnet’s solderability, especially for PCB (printed circuit board) adhesion. It also makes the magnet cleaner, which is good for vacuum and medical applications.

- Certifications: ISO9001:2008, ISO/Ts16949:2009, RoHS. ISO9001:2008 is a quality management system certification, ensures product quality is consistent. ISO/16949:2009 is for the automotive industry, which means the product is suitable for automotive applications. RoHS means the product restricts the use of certain hazardous substances, environmentally friendly.

- Energy Product Range: SmCo magnets have energy products from 16 MGOe to 33 MGOe. You can choose based on your application’s magnetic field strength requirements.

- Demagnetization Resistance and Thermal Stability: They have high resistance to demagnetizing influences and excellent thermal stability. The change of flux density of the SmCo magnet can be lower than 5%. 100 ° Sm-Co is the top choice for the most demanding motor applications, turbo-machinery, and traveling-wave tube, where stable magnetic performance under varying conditions is critical.

- Corrosion Resistance: SmCo Magnet has much higher corrosion resistance than NdFeB. For most applications, no coating or plating is required. But still, it’s recommended to coat the SmCo magnet in acidic and high-moisture conditions. In medical applications, this high corrosion resistance brings high comfort,t and coatings and metal plating can further increase the cleanliness of the magnet.

Samarium Cobalt Magnets Application Examples

- Speaker Field: As speaker magnets, they produce a stable and strong magnetic field. This interacts with the voice coil to convert electrical signals into sound signals accurately, improving the sound quality of speakers.

- Industrial Field: In industrial applications, they are used in various equipment. For example, in magnetic fixtures, they hold workpieces firmly, ensure machining accuracy. Magnetic separators separate ferromagnetic impurities from materials, protecting the normal operation of production lines.

- Motor Field: SmCo magnets provide a stable magnetic field in motors. This is key to efficient conversion of electrical energy into mechanical energy, making them ideal for high-performance and demanding motor applications.

Samarium Cobalt Magnets Customization Options

Customized to Requirements: We can customize these magnets to customers’ specific needs, including size, shape modifications (while keeping the disc shape base), and magnetic properties. So the magnets fit perfectly into the application requirements.

Samarium Cobalt Magnets Installation and Maintenance

- Installation: Handle the magnets with care during installation to avoid mechanical damage. Ensure proper alignment and positioning according to the equipment design to optimize the magnetic field.

- Maintenance: In normal use, keep the magnets clean. In harsh environments (acidic or high moisture), regularly inspect the coating for any signs of wear or corrosion. If the nickel coating is damaged, it may need to be re-coated or repaired to maintain the magnet’s performance and life.

Samarium Cobalt Magnets Product Advantages

- Super Performance: High magnetic properties, excellent thermal stability, strong corrosion resistance. SmCo magnets perform well in many applications.

- Certified: Multiple certifications (ISO9001:2008, ISO/Ts16949:2009, RoHS) guarantee product quality, environmental friendliness, and industry suitability.

- Customization: The ability to customize the magnets allows them to fit different application needs, maximize performance.

- Wide Application: Suitable for speaker, industrial, and motor applications, these magnets have a wide market application.

Frequently Asked Questions—Samarium Cobalt Magnets

1. Why nickel coating for these SmCo magnets?

Nickel coating is chosen for two reasons. Firstly, it can facilitate soldering, especially for applications where the magnet needs to be attached to a printed circuit board. Secondly, it provides better cleanliness, which is crucial for vacuum and medical applications where a high level of hygiene is required.

2. What do the certifications (ISO9001:2008, ISO/Ts16949:2009, RoHS) mean to me as a customer?

ISO9001:2008 means our quality management system is in place, so you can expect consistent product quality. ISO/Ts16949:2009 is specific to the automotive industry, so if you are going to use these magnets in automotive-related applications, it means we comply with automotive quality standards. RoHS means our product restricts the use of certain hazardous substances, which is important for environmental protection and applications where environmental regulations are required.

3. Can I use these SmCo magnets in high temperature environments?

Yes, SmCo magnets are suitable for high-temperature environments. They have good thermal stability, with flux density change less than 5% per 100 °C. They are a good choice for applications like turbo machinery and traveling wave tubes, where high temperature is involved. However, the maximum operating temperature may vary depending on the grade and application details, so please consult us for more information

4. Do I need to coat the SmCo magnet for all applications?

Generally, the corrosion resistance of SmCo Magnet is higher than some other magnets like NdFeB, and for most applications, no coating or plating is required. But in acidic and high moisture conditions, it is recommended to coat the SmCo magnet to protect it from corrosion and ensure its long-term performance. And in applications where cleanability or soldering ability is required (like vacuum and medical applications), coating like nickel plating can be beneficial.