Ferrite magnetics are permanent magnetic materials made up of strontium oxide (SrO) or barium oxide (BaO) and iron oxide (Fe₂O₃). They are known for their high electrical resistivity and dielectric properties and are used in high-frequency, low-current applications, critical for electronics and telecommunications. Fe₃O₄ (magnetite), the simplest natural ferrite, has been used for centuries as a magnetic material.

Classification: Hard Ferrite vs. Soft Ferrite

Ferrite magnetics are divided into two categories, each for different magnetic behavior:

1. Hard Ferrite (Permanent Ferrite)——Ferrite Magnetics

- Key Feature: Retains magnetization after external magnetic fields are removed, good for long term magnetic applications.

- Composition: Based on barium ferrite (BaFe₁₂O₁₉) or strontium ferrite (SrFe₁₂O₁₉), hexagonal crystal structure.

- Applications: Small Motors: U-shaped hard ferrite magnets drive fans, pumps and robotics in appliances. Audio Equipment: Speakers, headphones and microphones use stable magnetism for sound generation. Industrial Uses: Magnetic separators, sensors and automotive components (e.g. ignition systems).

- Advantages: Low cost, corrosion resistance and mass production.

2. Soft Ferrite——Ferrite Magnetics

- Key Feature: Magnetizes and demagnetizes in the presence of external fields, loses magnetism when the field is removed.

- Composition: Manganese-zinc ferrite (Mn-ZnFe₂O₄) and nickel-zinc ferrite (Ni-ZnFe₂O₄), cubic crystal structure.

- Applications: Power Electronics: Transformers, inductors and coils in inverters and switch-mode power supplies. Communication Systems: Ferrite beads and chokes in cables and circuit boards. Consumer Electronics: Used in wireless chargers, RFID tags and antenna components.

- Advantages: High permeability at low frequency and low energy loss in AC applications.

Ferrite Magnetics Chemical and Physical Properties

Ferrite Magnetics Chemical Composition

- Main ingredients: Iron oxide (Fe₂O₃) and metal oxides (e.g. BaO, SrO, MnO, ZnO).

- General formula: MFe₂O₄ (M = Mn, Fe, Co, Ni, Cu, Mg, Zn, etc.), spinel or hexagonal structure.

Ferrite Magnetics Physical Traits

- Hardness & Brittleness: Rigid and prone to crack under impact, handle with care during machining.

- Corrosion Resistance: Naturally rust and chemical resistant, no coating required in most cases.

- Thermal Stability: Works up to 200°C for hard ferrites.

Manufacturing Process

Ferrite magnetics are made via powder metallurgy process:

- Mixing: Blending metal oxides (e.g. BaCO₃, Fe₂O₃) in precise ratio.

- Calcination: Heating the mixture to form ferrite powder.

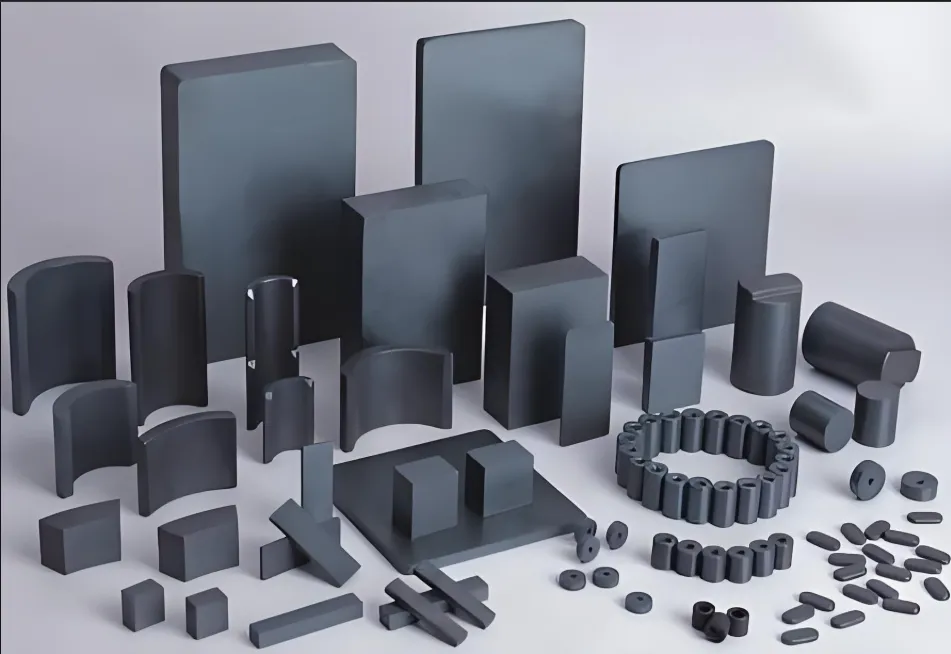

- Molding: Pressing the powder into shapes (e.g. blocks, rings, arcs) using dies.

- Sintering: High temperature firing (1,000-1,300°C) to densify the material and enhance magnetic properties.

- Finishing: Grinding, drilling or coating (for special applications) to meet dimensional requirements.

Why Choose Ferrite Magnetics?

- Cost Effective: Lower production cost compared to rare earth magnets (e.g. NdFeB).

- Energy Efficiency: Minimal eddy current loss in high frequency applications.

- Environmental Stability: Moisture, oxidation and harsh environment resistant without additional treatment.