NdFeb Magnet Performance Table

| Item | Grade | Remanence induc7on | Coercive force | Intrinsic Coercive force | Maximum Energy product | Working Temperature | Density | ||||

| Br | HcB | HcJ | (BH)max | Tw | ρ | ||||||

| T | KGs | KA/m | KOe | KA/m | KOe | KJ/m³ | MGOe | ℃ | g/cm3 | ||

| General Process | |||||||||||

| N | N35 | 1.17-1.22 | 11.7-12.2 | ≥868 | ≥10.9 | ≥955 | ≥12 | 263-287 | 33-36 | ≤80 | ≥7.5 |

| N38 | 1.22-1.26 | 12.2-12.6 | ≥899 | ≥11.3 | ≥955 | ≥12 | 287-310 | 36-39 | ≤80 | ≥7.5 | |

| N40 | 1.26-1.29 | 12.6-12.9 | ≥907 | ≥11.4 | ≥955 | ≥12 | 302-326 | 38-41 | ≤80 | ≥7.5 | |

| N42 | 1.29-1.33 | 12.9-13.3 | ≥915 | ≥11.5 | ≥955 | ≥12 | 318-342 | 40-43 | ≤80 | ≥7.5 | |

| N45 | 1.32-1.38 | 13.2-13.8 | ≥915 | ≥11.5 | ≥955 | ≥12 | 342-366 | 43-46 | ≤80 | ≥7.5 | |

| N48 | 1.37-1.42 | 13.7-14.2 | ≥876 | ≥11.0 | ≥955 | ≥12 | 366-390 | 46-49 | ≤80 | ≥7.5 | |

| N50 | 1.40-1.45 | 14.0-14.5 | ≥836 | ≥10.5 | ≥955 | ≥12 | 374-406 | 47-51 | ≤80 | ≥7.5 | |

| N52 | 1.42-1.48 | 14.2-14.8 | ≥836 | ≥10.5 | ≥955 | ≥12 | 390-422 | 49-53 | ≤80 | ≥7.5 | |

| N54 | 1.44-1.50 | 14.4-15.0 | ≥796 | ≥10.0 | ≥875 | ≥11 | 406-438 | 51-55 | ≤60 | ≥7.5 | |

| N56 | 1.46-1.52 | 14.6-15.2 | ≥796 | ≥10.0 | ≥875 | ≥11 | 414-446 | 52-56 | ≤60 | ≥7.5 | |

| M | N33M | 1.13-1.17 | 11.3-11.7 | ≥836 | ≥10.5 | ≥1114 | ≥14 | 247-271 | 31-34 | ≤100 | ≥7.5 |

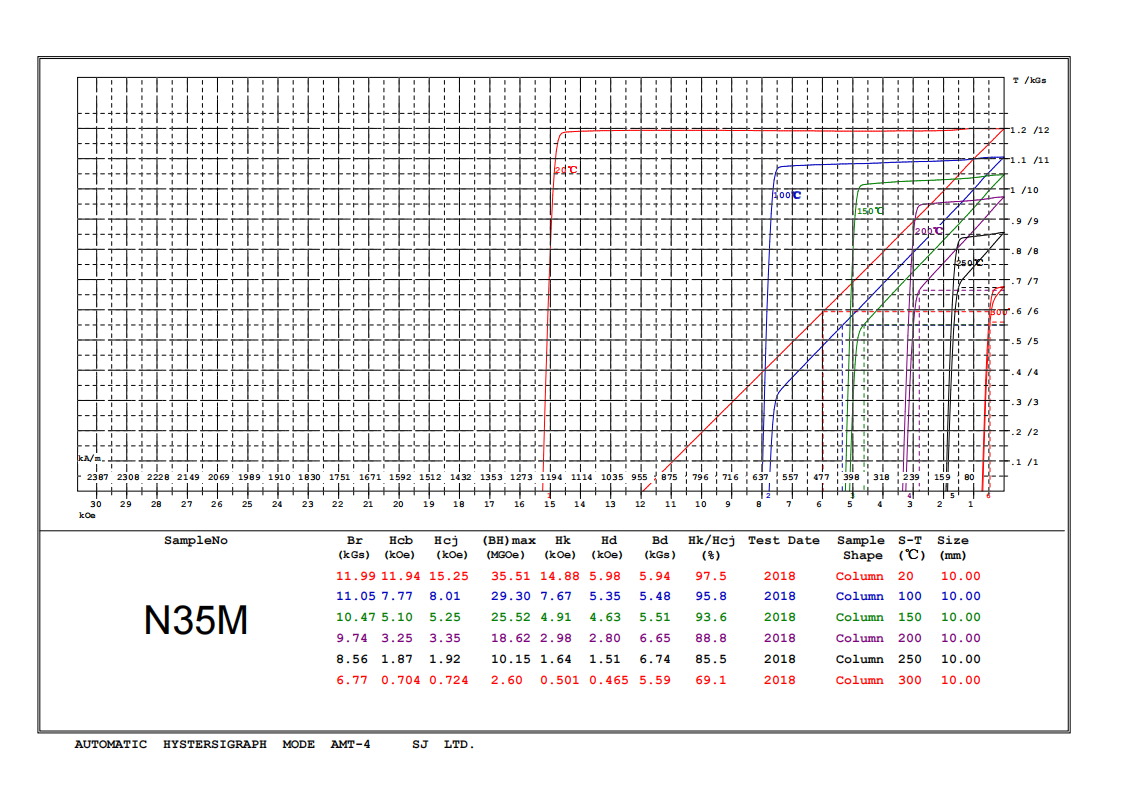

| N35M | 1.17-1.22 | 11.7-12.2 | ≥868 | ≥10.9 | ≥1114 | ≥14 | 263-287 | 33-36 | ≤100 | ≥7.5 | |

| N38M | 1.22-1.26 | 12.2-12.6 | ≥899 | ≥11.3 | ≥1114 | ≥14 | 287-310 | 36-39 | ≤100 | ≥7.5 | |

| N40M | 1.26-1.29 | 12.6-12.9 | ≥923 | ≥11.6 | ≥1114 | ≥14 | 302-326 | 38-41 | ≤100 | ≥7.5 | |

| N42M | 1.29-1.33 | 12.9-13.3 | ≥955 | ≥12.0 | ≥1114 | ≥14 | 318-342 | 40-43 | ≤100 | ≥7.5 | |

| N45M | 1.32-1.38 | 13.2-13.8 | ≥971 | ≥12.2 | ≥1114 | ≥14 | 342-366 | 43-46 | ≤100 | ≥7.5 | |

| N48M | 1.37-1.42 | 13.7-14.2 | ≥955 | ≥12.5 | ≥1114 | ≥14 | 366-390 | 46-49 | ≤100 | ≥7.5 | |

| N50M | 1.40-1.45 | 14.0-14.5 | ≥1035 | ≥13.0 | ≥1114 | ≥14 | 374-406 | 47-51 | ≤100 | ≥7.5 | |

| N52M | 1.42-1.48 | 14.2-14.8 | ≥1035 | ≥13.0 | ≥1114 | ≥14 | 390-422 | 49-53 | ≤100 | ≥7.5 | |

| N54M | 1.44-1.50 | 14.4-15.0 | ≥1035 | ≥13.0 | ≥1114 | ≥14 | 406-438 | 51-55 | ≤100 | ≥7.5 | |

| N56M | 1.46-1.52 | 14.6-15.2 | ≥995 | ≥12.5 | ≥1035 | ≥13 | 414-446 | 52-56 | ≤100 | ≥7.5 | |

| H | N33H | 1.13-1.17 | 11.3-11.7 | ≥836 | ≥10.5 | ≥1353 | ≥17 | 247-271 | 31-34 | ≤120 | ≥7.5 |

| N35H | 1.17-1.22 | 11.7-12.2 | ≥868 | ≥10.9 | ≥1353 | ≥17 | 263-287 | 33-36 | ≤120 | ≥7.5 | |

| N38H | 1.22-1.26 | 12.2-12.6 | ≥915 | ≥11.5 | ≥1353 | ≥17 | 287-310 | 36-39 | ≤120 | ≥7.5 | |

| N40H | 1.26-1.29 | 12.6-12.9 | ≥939 | ≥11.8 | ≥1353 | ≥17 | 302-326 | 38-41 | ≤120 | ≥7.5 | |

| N42H | 1.29-1.33 | 12.9-13.3 | ≥955 | ≥12.0 | ≥1353 | ≥17 | 318-342 | 40-43 | ≤120 | ≥7.5 | |

| N45H | 1.32-1.38 | 13.2-13.8 | ≥995 | ≥12.5 | ≥1353 | ≥17 | 342-366 | 43-46 | ≤120 | ≥7.5 | |

| N48H | 1.37-1.42 | 13.7-14.2 | ≥995 | ≥12.5 | ≥1353 | ≥17 | 366-390 | 46-49 | ≤120 | ≥7.5 | |

| N50H | 1.40-1.45 | 14.0-14.5 | ≥1035 | ≥13.0 | ≥1353 | ≥17 | 374-406 | 47-51 | ≤120 | ≥7.5 | |

| N52H | 1.42-1.48 | 14.2-14.8 | ≥1035 | ≥13.0 | ≥1353 | ≥17 | 390-422 | 49-53 | ≤120 | ≥7.5 | |

| SH | N33SH | 1.13-1.17 | 11.3-11.7 | ≥844 | ≥10.6 | ≥1592 | ≥20 | 247-271 | 31-34 | ≤150 | ≥7.5 |

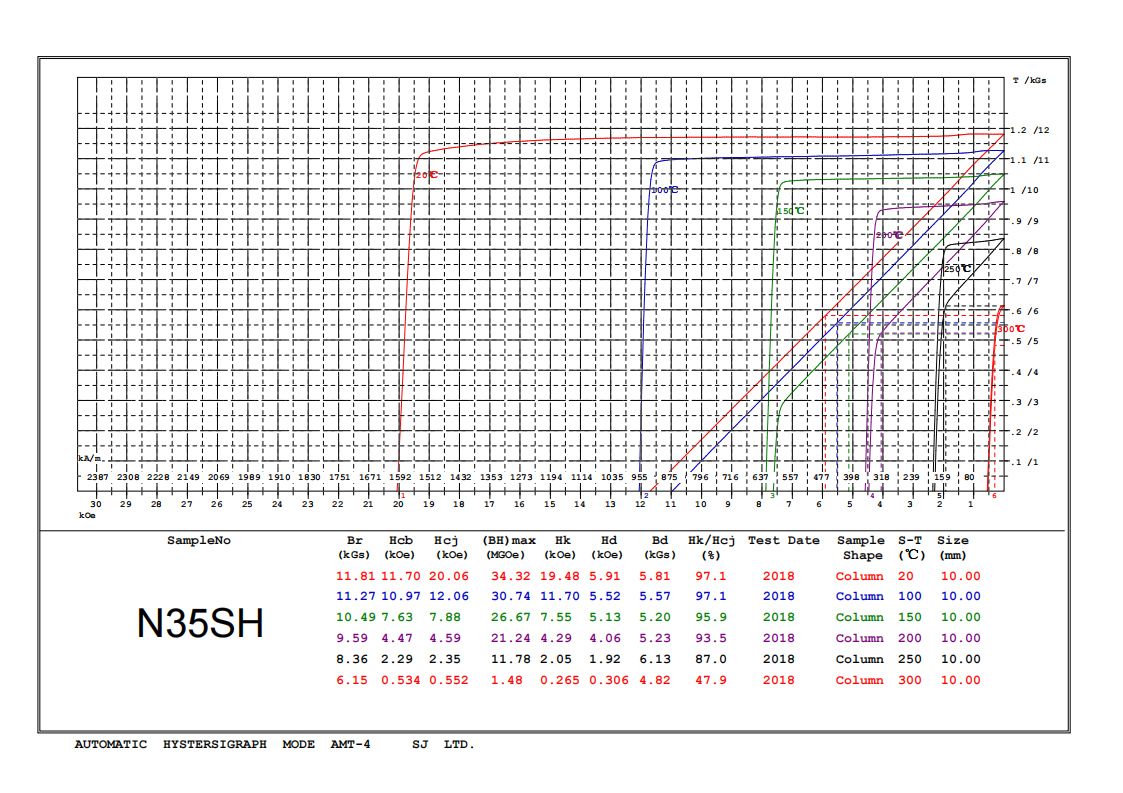

| N35SH | 1.17-1.22 | 11.7-12.2 | ≥876 | ≥11.0 | ≥1592 | ≥20 | 263-287 | 33-36 | ≤150 | ≥7.5 | |

| N38SH | 1.22-1.26 | 12.2-12.6 | ≥915 | ≥11.5 | ≥1592 | ≥20 | 287-310 | 36-39 | ≤150 | ≥7.5 | |

| N40SH | 1.26-1.29 | 12.6-12.9 | ≥939 | ≥11.8 | ≥1592 | ≥20 | 302-326 | 38-41 | ≤150 | ≥7.5 | |

| N42SH | 1.29-1.33 | 12.9-13.3 | ≥955 | ≥12.0 | ≥1592 | ≥20 | 318-342 | 40-43 | ≤150 | ≥7.5 | |

| N45SH | 1.32-1.38 | 13.2-13.8 | ≥995 | ≥12.5 | ≥1592 | ≥20 | 342-366 | 43-46 | ≤150 | ≥7.5 | |

| N48SH | 1.37-1.42 | 13.7-14.2 | ≥995 | ≥12.5 | ≥1592 | ≥20 | 366-390 | 46-49 | ≤150 | ≥7.5 | |

| N50SH | 1.40-1.45 | 14.0-14.5 | ≥1035 | ≥13.0 | ≥1592 | ≥20 | 374-406 | 47-51 | ≤150 | ≥7.5 | |

| N52SH | 1.42-1.48 | 14.2-14.8 | ≥1035 | ≥13.0 | ≥1592 | ≥20 | 390-422 | 49-53 | ≤150 | ≥7.5 | |

| UH | N28UH | 1.04-1.08 | 10.4-10.8 | ≥764 | ≥9.6 | ≥1990 | ≥25 | 207-231 | 26-29 | ≤180 | ≥7.5 |

| N30UH | 1.08-1.13 | 10.8-11.3 | ≥812 | ≥10.2 | ≥1990 | ≥25 | 223-247 | 28-31 | ≤180 | ≥7.5 | |

| N33UH | 1.13-1.17 | 11.3-11.7 | ≥852 | ≥10.7 | ≥1990 | ≥25 | 247-271 | 31-34 | ≤180 | ≥7.5 | |

| N35UH | 1.17-1.22 | 11.7-12.2 | ≥876 | ≥11.0 | ≥1990 | ≥25 | 263-287 | 33-36 | ≤180 | ≥7.5 | |

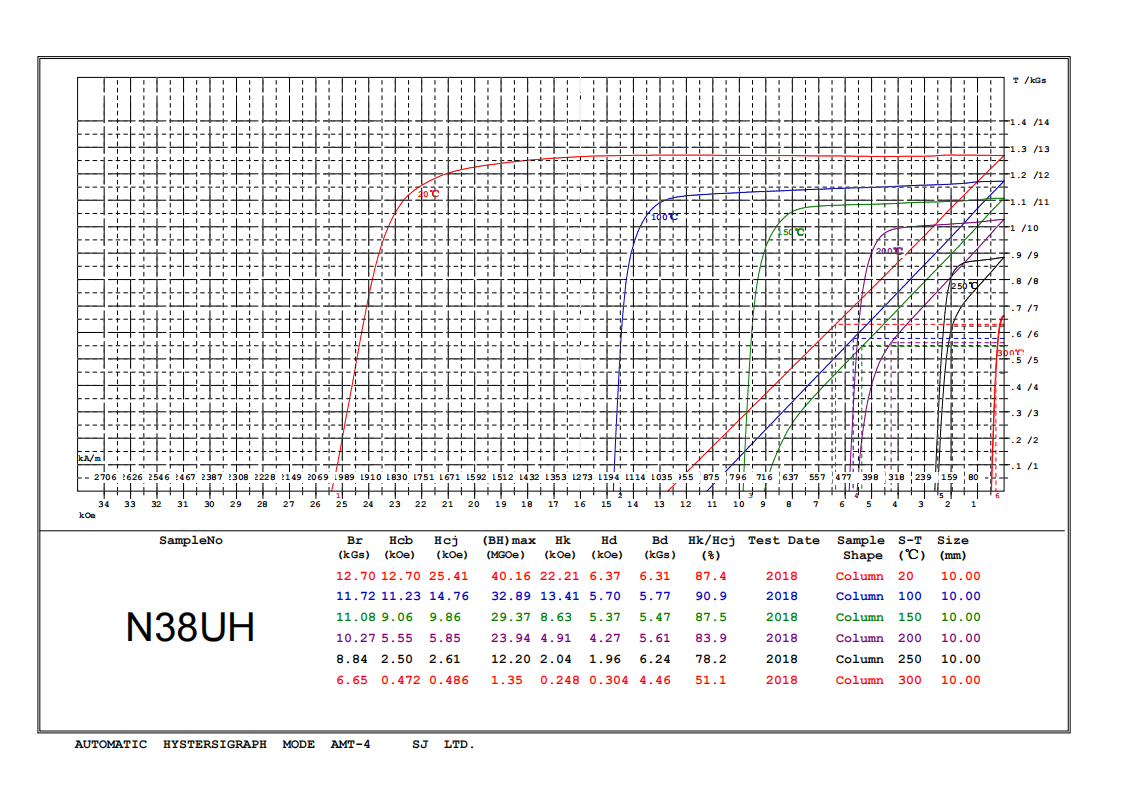

| N38UH | 1.22-1.26 | 12.2-12.6 | ≥915 | ≥11.5 | ≥1990 | ≥25 | 287-310 | 36-39 | ≤180 | ≥7.5 | |

| N40UH | 1.26-1.29 | 12.6-12.9 | ≥939 | ≥11.8 | ≥1990 | ≥25 | 302-326 | 38-41 | ≤180 | ≥7.5 | |

| N42UH | 1.29-1.33 | 12.9-13.3 | ≥955 | ≥12.0 | ≥1990 | ≥25 | 318-342 | 40-43 | ≤180 | ≥7.5 | |

| N45UH | 1.32-1.38 | 13.2-13.8 | ≥995 | ≥12.5 | ≥1990 | ≥25 | 342-366 | 43-46 | ≤180 | ≥7.5 | |

| EH | N28EH | 1.04-1.08 | 10.4-10.8 | ≥764 | ≥9.6 | ≥2388 | ≥30 | 207-231 | 26-29 | ≤200 | ≥7.5 |

| N30EH | 1.08-1.13 | 10.8-11.3 | ≥812 | ≥10.2 | ≥2388 | ≥30 | 223-247 | 28-31 | ≤200 | ≥7.5 | |

| N33EH | 1.13-1.17 | 11.3-11.7 | ≥852 | ≥10.7 | ≥2388 | ≥30 | 247-271 | 31-34 | ≤200 | ≥7.5 | |

| N35EH | 1.17-1.22 | 11.7-12.2 | ≥876 | ≥11.0 | ≥2388 | ≥30 | 263-287 | 33-36 | ≤200 | ≥7.5 | |

| N38EH | 1.22-1.26 | 12.2-12.6 | ≥915 | ≥11.5 | ≥2388 | ≥30 | 287-310 | 36-39 | ≤200 | ≥7.5 | |

| N40EH | 1.26-1.29 | 12.6-12.9 | ≥939 | ≥11.8 | ≥2388 | ≥30 | 302-326 | 38-41 | ≤200 | ≥7.5 | |

| N42EH | 1.29-1.33 | 12.9-13.3 | ≥955 | ≥12.0 | ≥2388 | ≥30 | 318-342 | 40-43 | ≤200 | ≥7.5 | |

| N45EH | 1.32-1.38 | 13.2-13.8 | ≥995 | ≥12.5 | ≥2308 | ≥29 | 342-366 | 43-46 | ≤200 | ≥7.5 | |

| AH | N28AH | 1.04-1.08 | 10.4-10.8 | ≥764 | ≥9.6 | ≥2786 | ≥35 | 207-231 | 26-29 | ≤220 | ≥7.5 |

| N30AH | 1.08-1.13 | 10.8-11.3 | ≥812 | ≥10.2 | ≥2786 | ≥35 | 223-247 | 28-31 | ≤220 | ≥7.5 | |

| N33AH | 1.13-1.17 | 11.3-11.7 | ≥852 | ≥10.7 | ≥2786 | ≥35 | 247-271 | 31-34 | ≤220 | ≥7.5 | |

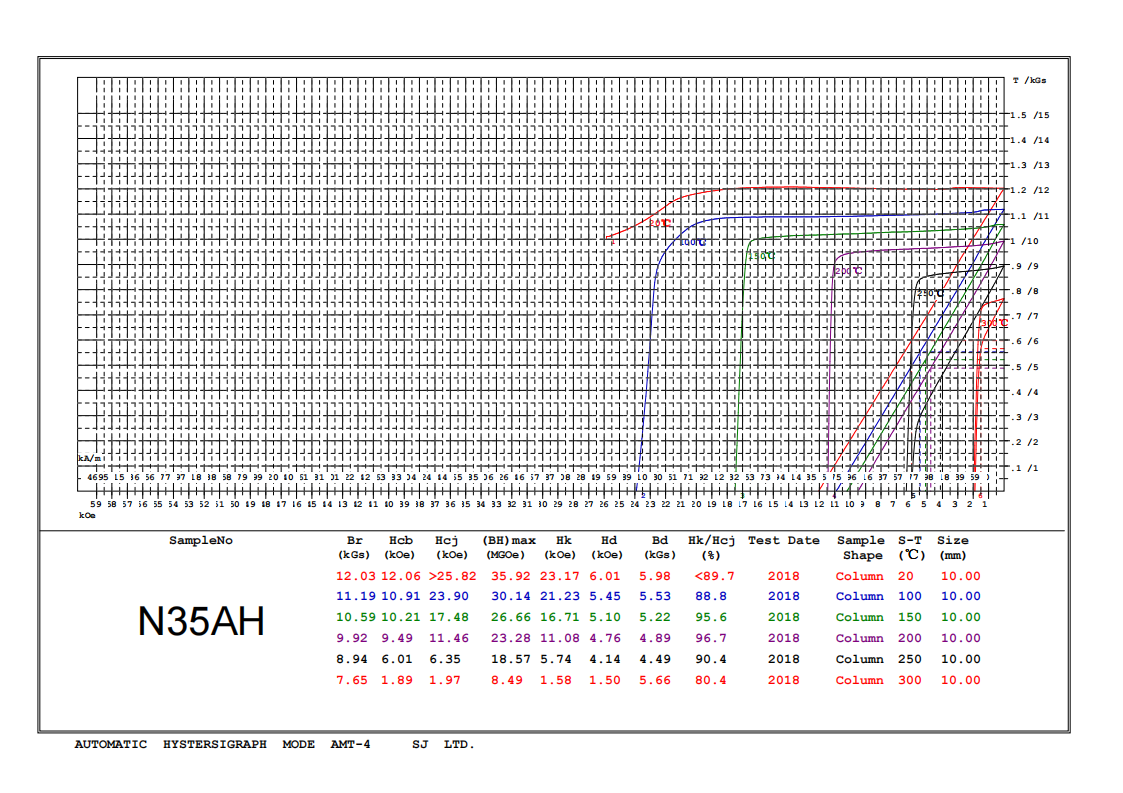

| N35AH | 1.17-1.22 | 11.7-12.2 | ≥876 | ≥11.0 | ≥2786 | ≥35 | 263-287 | 33-36 | ≤220 | ≥7.5 | |

| N38AH | 1.22-1.26 | 12.2-12.6 | ≥923 | ≥11.6 | ≥2786 | ≥35 | 287-310 | 36-39 | ≤220 | ≥7.5 | |

| N40AH | 1.26-1.29 | 12.6-12.9 | ≥939 | ≥11.8 | ≥2786 | ≥35 | 302-326 | 38-41 | ≤220 | ≥7.5 | |

| N42AH | 1.29-1.33 | 12.9-13.3 | ≥955 | ≥12.0 | ≥2707 | ≥34 | 318-342 | 40-43 | ≤220 | ≥7.5 | |

| Diffusion Process | |||||||||||

| H | N54H | 1.44-1.50 | 14.4-15.0 | ≥1035 | ≥13.0 | ≥1353 | ≥17 | 406-438 | 51-55 | ≤120 | ≥7.5 |

| SH | N48SH | 1.37-1.42 | 13.7-14.2 | ≥995 | ≥12.5 | ≥1592 | ≥20 | 366-390 | 46-49 | ≤150 | ≥7.5 |

| N50SH | 1.40-1.45 | 14.0-14.5 | ≥1035 | ≥13.0 | ≥1592 | ≥20 | 374-406 | 47-51 | ≤150 | ≥7.5 | |

| N52SH | 1.42-1.48 | 14.2-14.8 | ≥1035 | ≥13.0 | ≥1592 | ≥20 | 390-422 | 49-53 | ≤150 | ≥7.5 | |

| N54SH | 1.44-1.50 | 14.4-15.0 | ≥1035 | ≥13.0 | ≥1512 | ≥19 | 406-438 | 51-55 | ≤150 | ≥7.5 | |

| UH | N45UH | 1.32-1.38 | 13.2-13.8 | ≥995 | ≥12.5 | ≥1990 | ≥25 | 342-366 | 43-46 | ≤180 | ≥7.5 |

| N48UH | 1.37-1.42 | 13.7-14.2 | ≥995 | ≥12.5 | ≥1990 | ≥25 | 366-390 | 46-49 | ≤180 | ≥7.5 | |

| N50UH | 1.40-1.45 | 14.0-14.5 | ≥1035 | ≥13.0 | ≥1990 | ≥25 | 374-406 | 47-51 | ≤180 | ≥7.5 | |

| N52UH | 1.42-1.48 | 14.2-14.8 | ≥1035 | ≥13.0 | ≥1910 | ≥24 | 390-422 | 49-53 | ≤180 | ≥7.5 | |

| N54UH | 1.44-1.50 | 14.4-15.0 | ≥1035 | ≥13.0 | ≥1910 | ≥24 | 406-438 | 51-55 | ≤180 | ≥7.5 | |

| EH | N40EH | 1.26-1.29 | 12.6-12.9 | ≥939 | ≥11.8 | ≥2388 | ≥30 | 302-326 | 38-41 | ≤200 | ≥7.5 |

| N42EH | 1.29-1.33 | 12.9-13.3 | ≥955 | ≥12.0 | ≥2388 | ≥30 | 318-342 | 40-43 | ≤200 | ≥7.5 | |

| N45EH | 1.32-1.38 | 13.2-13.8 | ≥995 | ≥12.5 | ≥2308 | ≥29 | 342-366 | 43-46 | ≤200 | ≥7.5 | |

| N48EH | 1.37-1.42 | 13.7-14.2 | ≥995 | ≥12.5 | ≥2388 | ≥30 | 366-390 | 46-49 | ≤200 | ≥7.5 | |

| N50EH | 1.40-1.45 | 14.0-14.5 | ≥1035 | ≥13.0 | ≥2308 | ≥29 | 374-406 | 47-51 | ≤200 | ≥7.5 | |

| AH | N40AH | 1.26-1.29 | 12.6-12.9 | ≥939 | ≥11.8 | ≥2786 | ≥35 | 302-326 | 38-41 | ≤220 | ≥7.5 |

| N42AH | 1.29-1.33 | 12.9-13.3 | ≥955 | ≥12.0 | ≥2707 | ≥34 | 318-342 | 40-43 | ≤220 | ≥7.5 | |

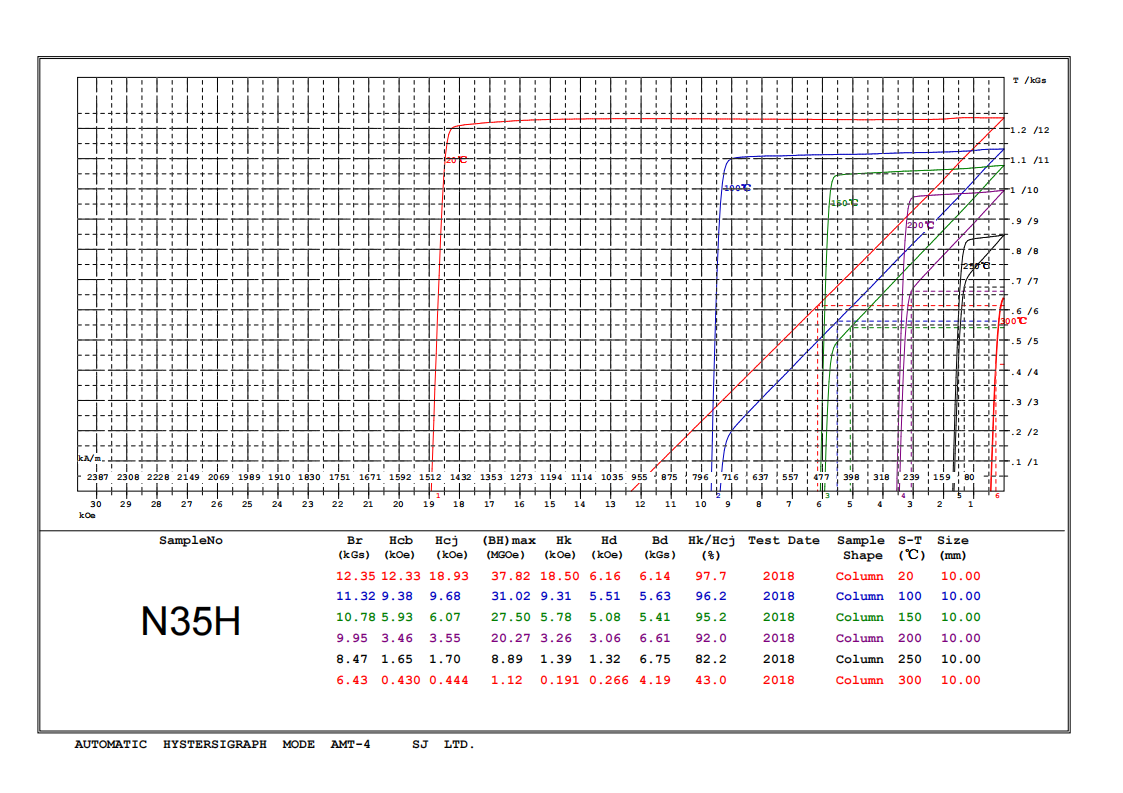

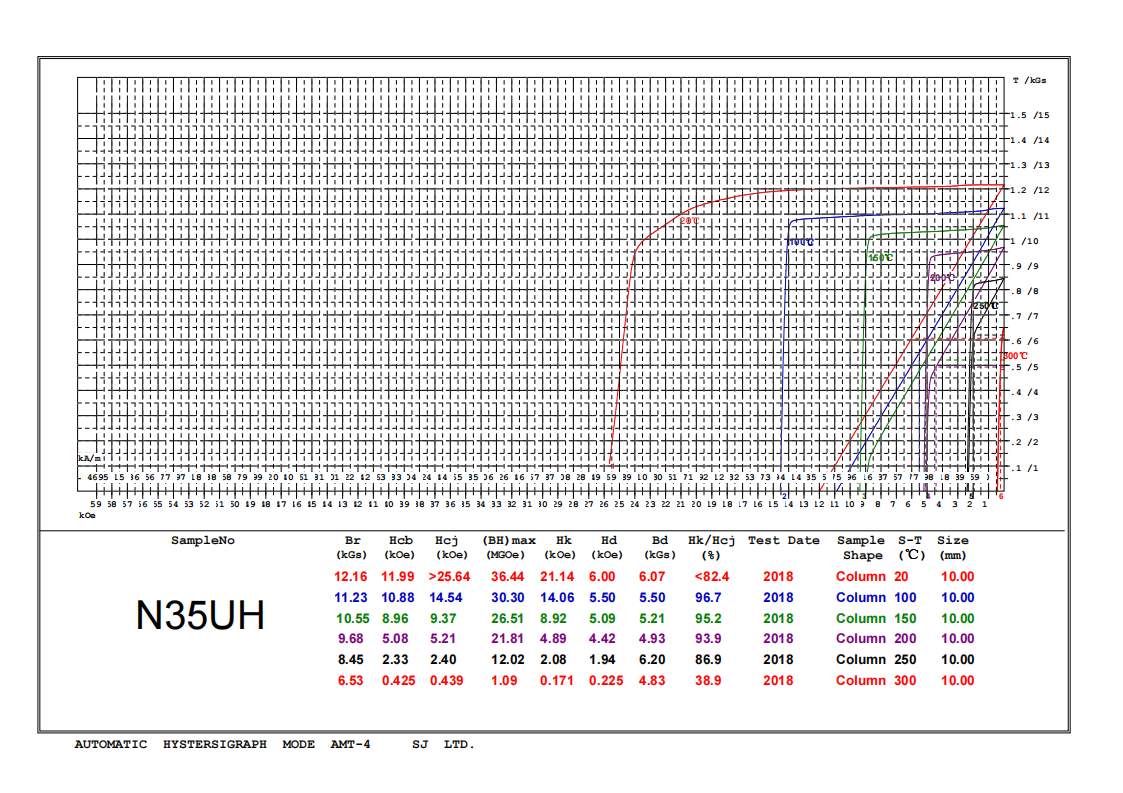

NdFeb Manget Demagnetization Curve

Request a call back?

Smco Magnet Performance Table

| Item | Grade | GBT 4180-2012 | Remanence induc7on | Coercive force | Intrinsic Coercive force | Maximum Energy product | Working Temperature | Density | Temperature Coefficient of Br | Temperature Coefficient of Hcj | ||||

| Br | HcB | HcJ | (BH)max | Tw | ρ | α (Br) | α (Hcj) | |||||||

| T | KGs | KA/m | KOe | KA/m | KOe | KJ/m³ | MGOe | ℃ | g/cm3 | %/℃ | %/℃ | |||

| Sm1Co5 | Sm1Co5-16 | XG1S135/96 | 0.79-0.84 | 7.9-8.4 | 620-660 | 7.8-8.3 | ≥1830 | ≥23 | 118-135 | 15-17 | ≤250 | 8.3 | -0.035 | -0.28 |

| Sm1Co5-18 | XG1S 143/160 | 0.84-0.89 | 8.4-8.9 | 660-700 | 8.3-8.8 | ≥1830 | ≥23 | 135-151 | 17-19 | ≤250 | 8.3 | -0.040 | -0.28 | |

| Sm1Co5-20 | XG1S 159/140 | 0.89-0.93 | 8.9-9.3 | 684-732 | 8.6-9.2 | ≥1830 | ≥23 | 150-167 | 19-21 | ≤250 | 8.3 | -0.045 | -0.28 | |

| Sm1Co5-22 | XG1S 175/140 | 0.92-0.96 | 9.2-9.6 | 710-756 | 8.9-9.5 | ≥1830 | ≥23 | 167-183 | 21-23 | ≤250 | 8.3 | -0.045 | -0.28 | |

| Sm1Co5-24 | / | 0.96-1.00 | 9.6-10.0 | 740-788 | 9.3-9.9 | ≥1830 | ≥23 | 183-199 | 23-25 | ≤250 | 8.3 | -0.045 | -0.28 | |

| Sm2Co17 | Sm2Co17-24L | / | 0.95-1.02 | 9.5-10.2 | 541-716 | 6.8-9.0 | 636-955 | 8-12 | 175-191 | 22-24 | ≤250 | 8.4 | -0.025 | -0.20 |

| Sm2Co17-26L | XGS 207/50 | 1.02-1.05 | 10.2-10.5 | 541-784 | 6.8-9.4 | 636-955 | 8-12 | 191-207 | 24-26 | ≤250 | 8.4 | -0.035 | -0.20 | |

| Sm2Co17-28L | XGS 223/50 | 1.05-1.08 | 10.5-10.8 | 541-764 | 6.8-9.6 | 636-955 | 8-12 | 207-220 | 26-28 | ≤250 | 8.4 | -0.035 | -0.20 | |

| Sm2Co17-30L | / | 1.08-1.15 | 10.8-11.5 | 541-796 | 6.8-10.0 | 636-955 | 8-12 | 220-240 | 28-30 | ≤250 | 8.4 | -0.035 | -0.20 | |

| Sm2Co17-32L | / | 1.10-1.15 | 11.0-11.5 | 541-812 | 6.8-10.2 | 636-955 | 8-12 | 230-255 | 29-32 | ≤250 | 8.4 | -0.035 | -0.20 | |

| Sm2Co17-26M | XGS 207/80 | 1.02-1.05 | 10.2-10.5 | 676-780 | 8.5-9.8 | 955-1433 | 12-18 | 191-207 | 24-26 | ≤300 | 8.4 | -0.035 | -0.20 | |

| Sm2Co17-28M | XGS 223/80 | 1.05-1.08 | 10.5-10.8 | 676-796 | 8.5-10.0 | 955-1433 | 12-18 | 207-220 | 26-28 | ≤300 | 8.4 | -0.035 | -0.20 | |

| Sm2Co17-30M | XGS 239/80 | 1.08-1.1 | 10.8-11.0 | 676-835 | 8.5-10.5 | 955-1433 | 12-18 | 220-240 | 28-30 | ≤300 | 8.4 | -0.035 | -0.20 | |

| Sm2Co17-32M | / | 1.10-1.13 | 11.0-11.3 | 676-852 | 8.5-10.7 | 955-1433 | 12-18 | 230-255 | 29-32 | ≤300 | 8.4 | -0.035 | -0.20 | |

| Sm2Co17 | Sm2Co17-33M | / | 1.13-1.15 | 11.3-11.5 | 820-870 | 10.3-10.9 | 955-1433 | 12-18 | 246-262 | 31-32 | ≤300 | 8.4 | -0.039 | -0.22 |

| Sm2Co17-22 | / | 0.93-0.97 | 9.3-9.7 | 676-740 | 8.5-9.3 | ≥1433 | ≥18 | 160-183 | 20-23 | ≤300 | 8.4 | -0.020 | -0.20 | |

| Sm2Co17-24 | / | 0.95-1.02 | 9.5-10.2 | 692-764 | 8.7-9.6 | ≥1433 | ≥18 | 175-191 | 22-24 | ≤300 | 8.4 | -0.025 | -0.20 | |

| Sm2Co17-26 | XGS 207/160 | 1.02-1.05 | 10.2-10.5 | 748-796 | 9.4-10.0 | ≥1433 | ≥18 | 191-207 | 24-26 | ≤300 | 8.4 | -0.030 | -0.20 | |

| Sm2Co17-28 | XGS 223/160 | 1.05-1.08 | 10.5-10.8 | 756-812 | 9.5-10.2 | ≥1433 | ≥18 | 207-220 | 26-28 | ≤300 | 8.4 | -0.035 | -0.20 | |

| Sm2Co17-30 | XGS 223/247 | 1.08-1.10 | 10.8-11.0 | 788-835 | 9.9-10.5 | ≥1433 | ≥18 | 220-240 | 28-30 | ≤300 | 8.4 | -0.035 | -0.20 | |

| Sm2Co17-32 | / | 1.10-1.13 | 11.0-11.3 | 812-860 | 10.2-10.8 | ≥1433 | ≥18 | 230-255 | 29-32 | ≤300 | 8.4 | -0.035 | -0.20 | |

| Sm2Co17-33 | / | 1.13-1.15 | 11.3-11.5 | 820-870 | 10.3-10.9 | ≥1433 | ≥18 | 246-262 | 31-32 | ≤300 | 8.4 | -0.039 | -0.22 | |

| Sm2Co17-24H | XGS 191/200 | 0.95-1.02 | 9.5-10.2 | 692-764 | 8.7-9.6 | ≥1990 | ≥25 | 175-191 | 22-24 | ≤350 | 8.4 | -0.025 | -0.20 | |

| Sm2Co17-26H | XGS 207/200 | 1.02-1.05 | 10.2-10.5 | 748-796 | 9.4-10.0 | ≥1990 | ≥25 | 191-207 | 24-26 | ≤350 | 8.4 | -0.030 | -0.20 | |

| Sm2Co17-28H | XGS 223/200 | 1.05-1.08 | 10.5-10.8 | 756-812 | 9.5-10.2 | ≥1990 | ≥25 | 207-220 | 26-28 | ≤350 | 8.4 | -0.035 | -0.20 | |

| Sm2Co17-30H | XGS 239/160 | 1.08-1.10 | 10.8-11.0 | 788-835 | 9.9-10.5 | ≥1990 | ≥25 | 220-240 | 28-30 | ≤350 | 8.4 | -0.035 | -0.20 | |

| Sm2Co17 | Sm2Co17-32H | / | 1.10-1.13 | 11.0-11.3 | 812-860 | 10.2-10.8 | ≥1990 | ≥25 | 230-255 | 29-32 | ≤350 | 8.4 | -0.035 | -0.20 |

| Sm2Co17-33H | / | 1.13-1.15 | 11.3-11.5 | 830-880 | 10.4-11 | ≥1990 | ≥25 | 246-262 | 31-32 | ≤350 | 8.4 | -0.039 | -0.22 | |

| Sm2Co17-TR | Sm2Co17-20TR | / | 0.9-0.94 | 9.0-9.4 | 661-732 | 8.3-9.2 | ≥1592 | ≥20 | 143-159 | 19-21 | ≤500 | 8.4 | -0.035 | -0.15 |

| Sm2Co17-LT | Sm2Co17-16LT | / | 0.80-0.84 | 8.0-8.4 | 605-669 | 7.6-8.4 | ≥1592 | ≥20 | 111-127 | 15-17 | ≤300 | 8.4 | Temperature range -50℃-20℃ 20℃-200℃ 200℃-300℃ | Temperature Coefficient of Br ±0.005%/℃ -0.008%/℃ -0.011%/℃ |

| Sm2Co17-18LT | / | 0.84-0.89 | 8.4-8.9 | 629-708 | 7.9-8.9 | ≥1592 | ≥20 | 127-143 | 17-19 | ≤300 | 8.4 | |||

| Sm2Co17-20LT | / | 0.89-0.94 | 8.9-9.4 | 661-732 | 8.3-9.2 | ≥1592 | ≥20 | 143-159 | 19-21 | ≤300 | 8.4 | |||

| Sm2Co17-22LT | / | 0.94-0.97 | 9.4-9.7 | 685-740 | 8.6-9.3 | ≥1592 | ≥20 | 159-175 | 21-23 | ≤300 | 8.4 | |||

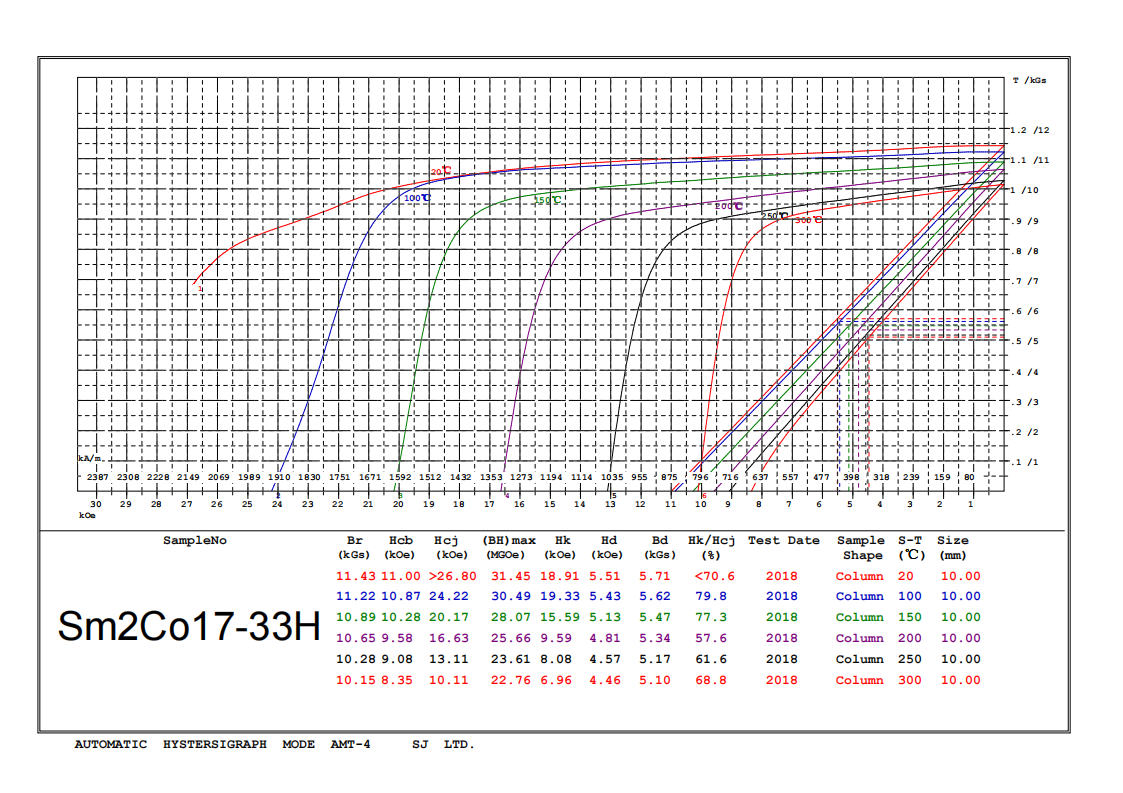

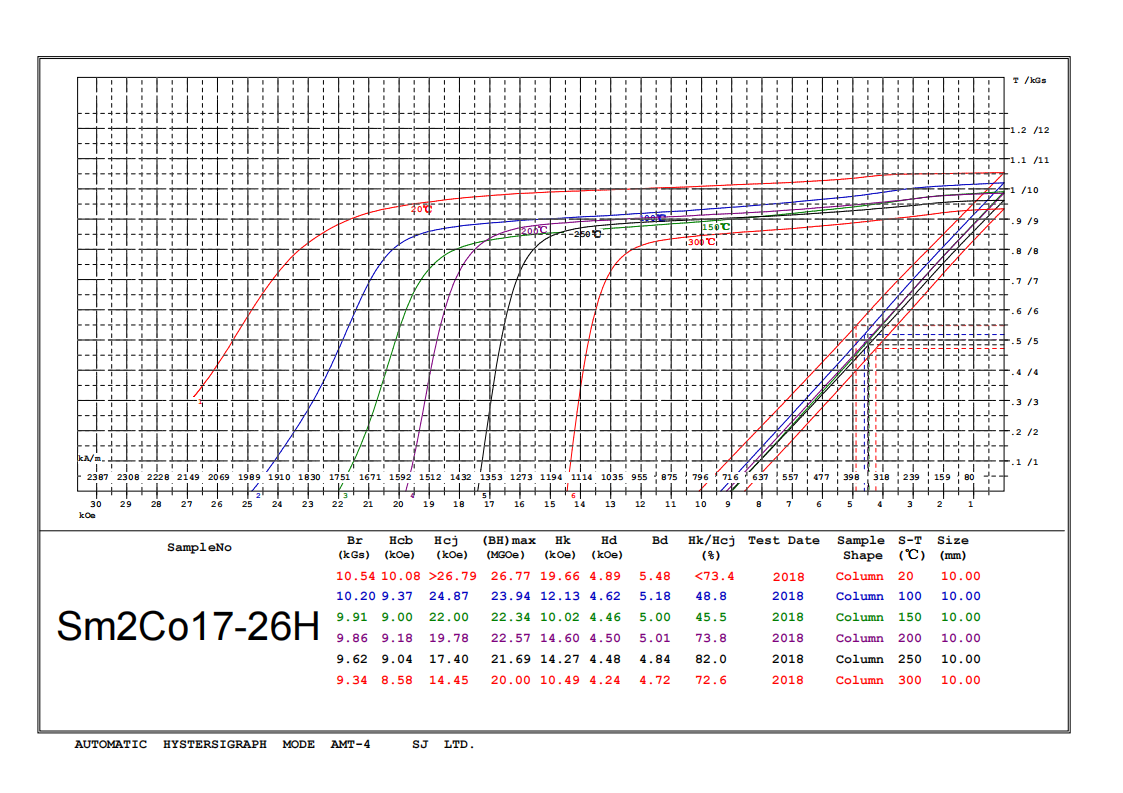

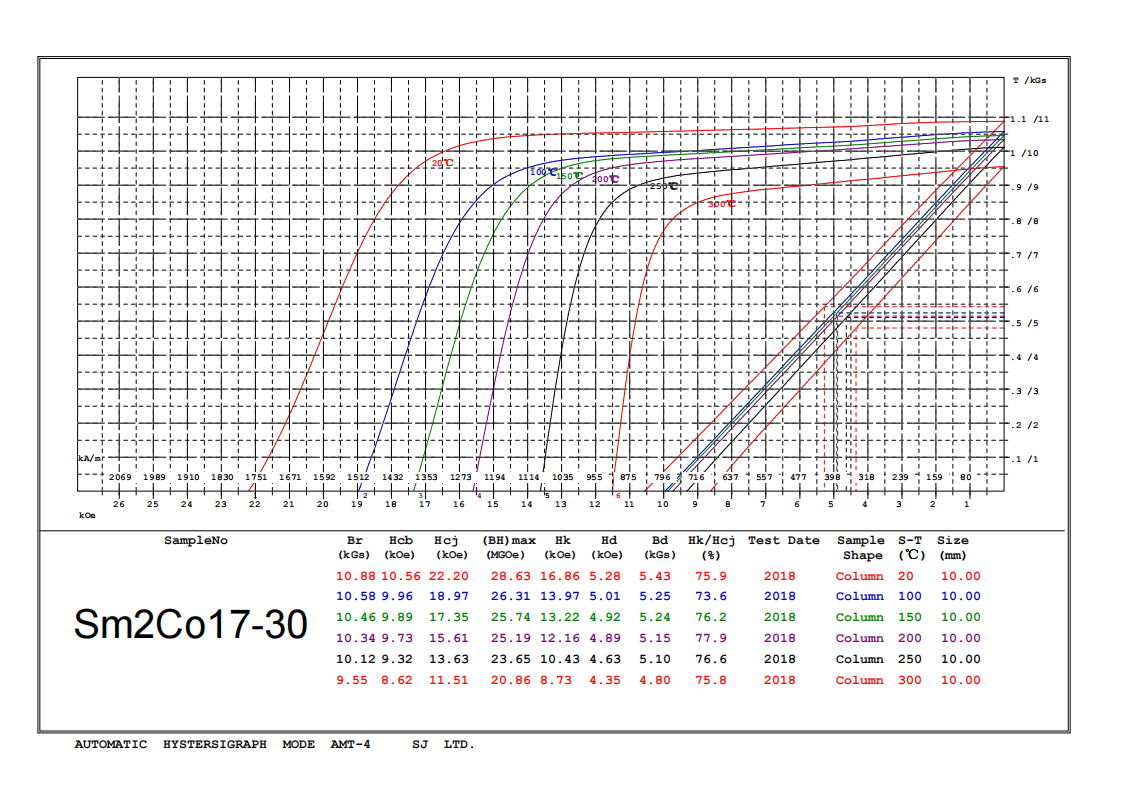

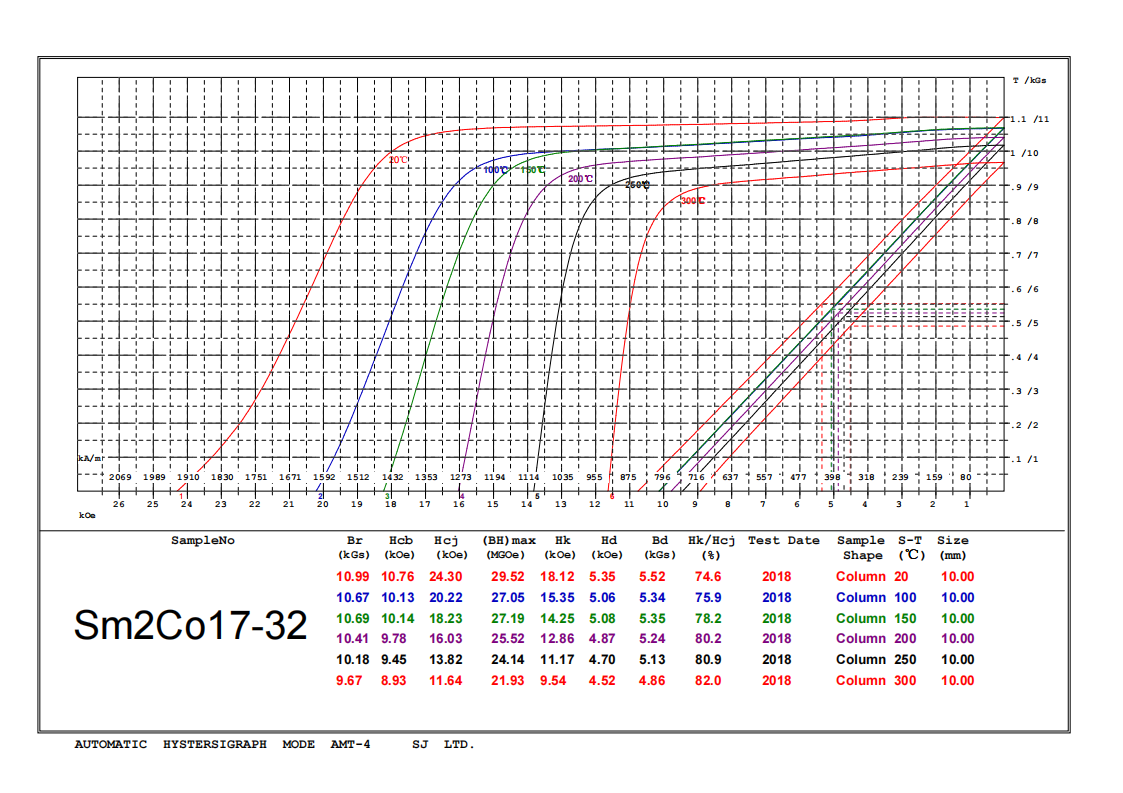

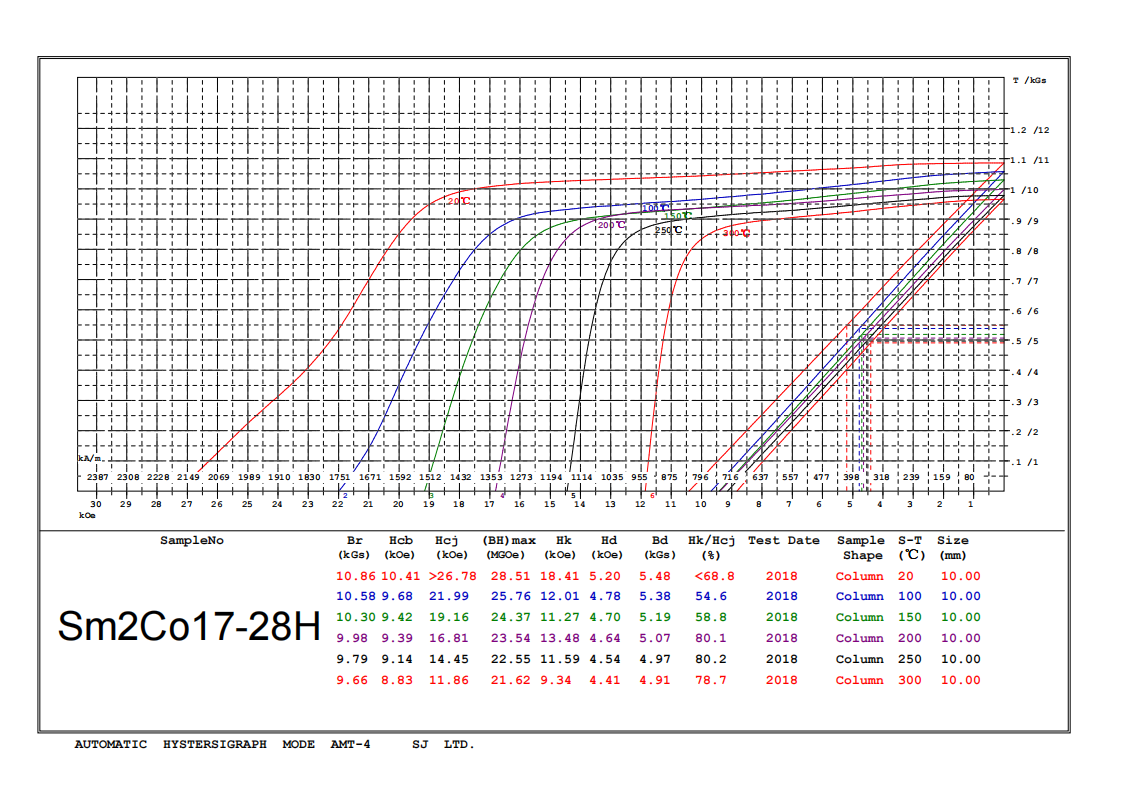

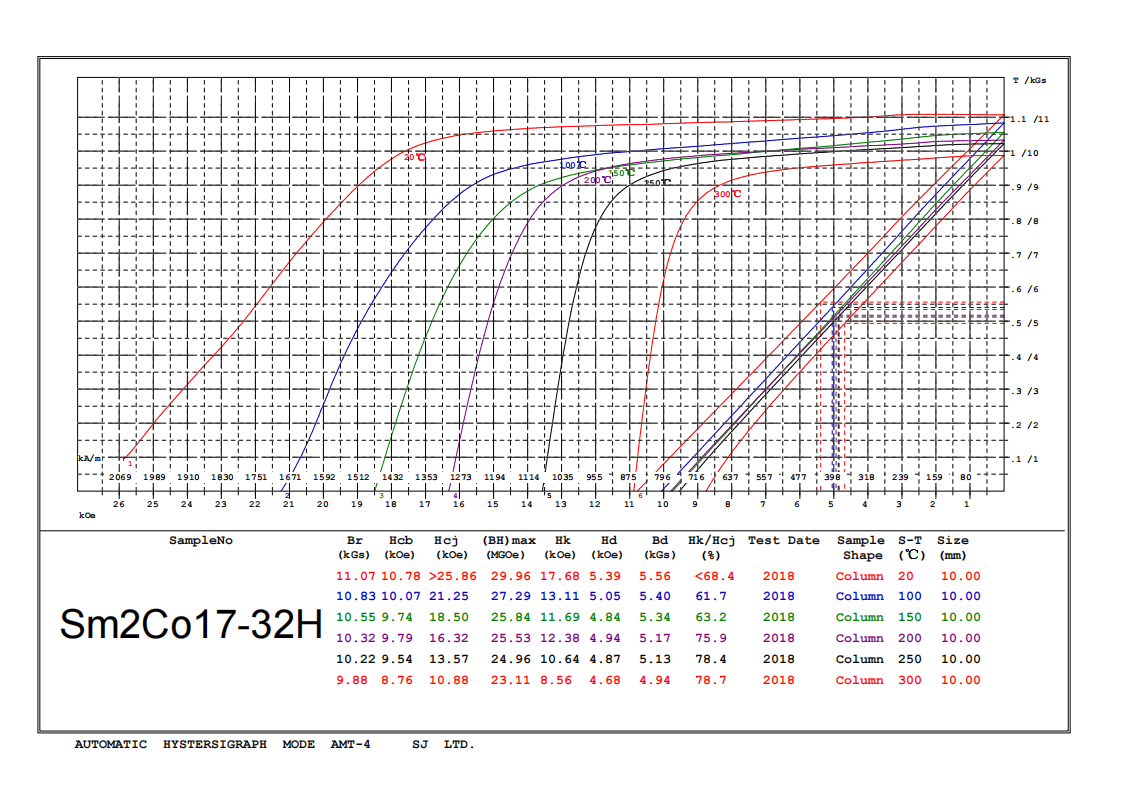

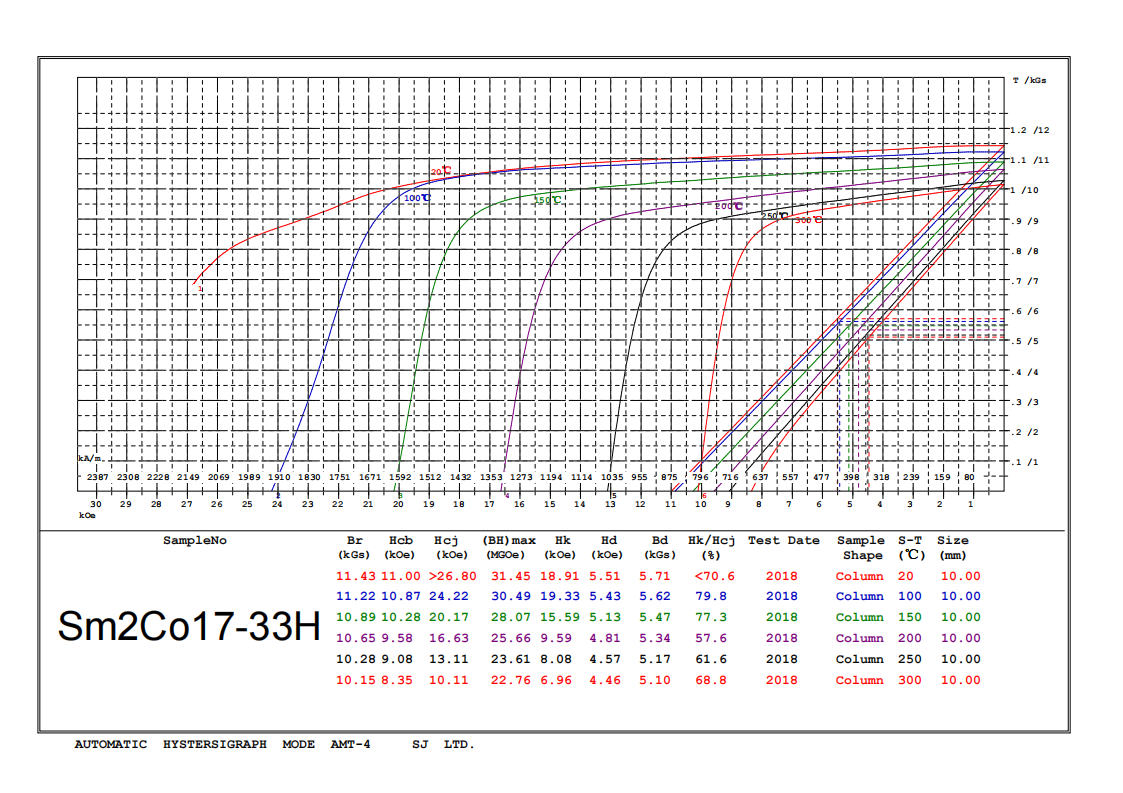

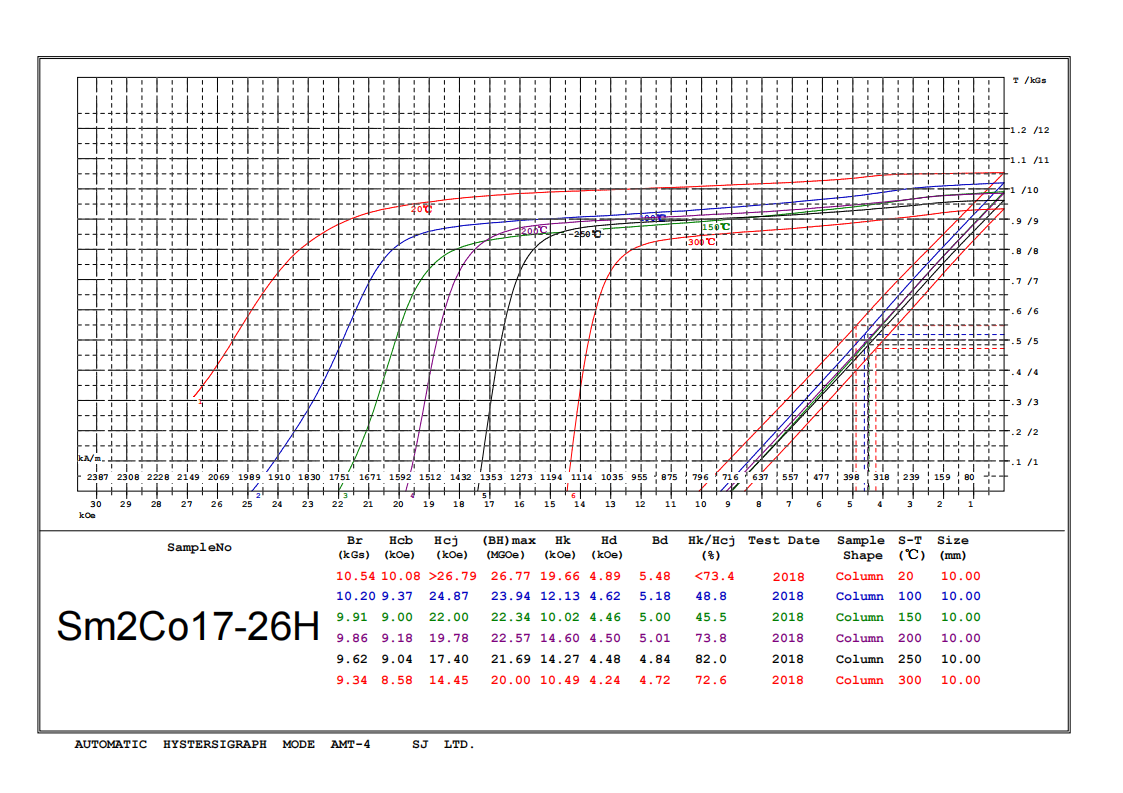

Smco Magnet Demagnetization Curve

Request a call back?

Alnico Magnet Performance Table

| Datasheet of Sintered AlNiCo at Room Temperature | ||||||||||||

| Item | Grade | Remanence induc7on | Coercive force | Intrinsic Coercive force | Maximum Energy product | Working Temperature | Density | Remark | ||||

| Br | Hcb | HcJ | (BH)max | Tw | ρ | |||||||

| T | KGs | KA/m | KOe | KA/m | KOe | KJ/m³ | MGOe | ℃ | g/cm3 | |||

| Sintered AlNiCo | PAlNiCo10/5 | 0.60-0.63 | 6.0-6.3 | 48-52 | 0.60-0.65 | 52-56 | 0.65-0.7 | 8-10 | 1.00-1.25 | ≤450 | 6.8 | Isotropic |

| PAlNiCo12/5 | 0.70-0.75 | 7.0-7.5 | 48-56 | 0.60-0.70 | 52-58 | 0.65-0.73 | 11-13 | 1.4-1.6 | ≤450 | 7.0 | ||

| PAlNiCo14/8 | 0.55-0.60 | 5.5-6.0 | 75-91 | 0.94-1.14 | 80-95 | 1.0-1.2 | 14.0-16.0 | 1.75-2.0 | ≤550 | 7.0 | ||

| PAlNiCo20/10 | 0.60-0.64 | 6.0-6.4 | 93-110 | 1.16-1.38 | 100-118 | 1.25-1.4 | 18.0-22.4 | 2.25-2.8 | ≤550 | 7.0 | ||

| PAlNiCo28/6 | 1.0-1.12 | 10.0-11.2 | 56-64 | 0.70-0.80 | 58-66 | 0.73-0.83 | 28-32 | 3.5-4.0 | ≤550 | 7.2 | Anisotropic | |

| PAlNiCo34/5 | 1.15-1.23 | 11.5-12.3 | 48-56 | 0.60-0.70 | 49-57 | 0.62-0.72 | 32-36 | 4.0-4.5 | ≤550 | 7.2 | ||

| PAlNiCo37/5 | 1.19-1.25 | 11.9-12.5 | 48-56 | 0.60-0.70 | 49-57 | 0.62-0.72 | 36-38 | 4.5-4.8 | ≤550 | 7.2 | ||

| PAlNiCo40/5 | 1.22-1.27 | 12.2-12.7 | 48-56 | 0.60-0.70 | 49-57 | 0.62-0.72 | 38-40 | 4.8-5.0 | ≤550 | 7.2 | ||

| PAlNiCo40/10 | 0.95-1.0 | 9.5-10.0 | 100-110 | 1.25-1.38 | 104-114 | 1.3-1.43 | 40-44 | 5.0-5.5 | ≤550 | 7.1 | ||

| PAlNiCo38/11 | 0.80-0.85 | 8.0-8.5 | 111-121 | 1.40-1.52 | 114-125 | 1.43-1.57 | 38-40 | 4.8-5.0 | ≤550 | 7.1 | ||

| PAlNiCo36/15 | 0.70-0.75 | 7.0-7.5 | 140-160 | 1.75-2.0 | 154-172 | 1.93-2.16 | 36-45 | 4.5-5.6 | ≤550 | 7.0 | ||

| PAlNiCo40/16 | 0.70-0.75 | 7.0-7.5 | 151-175 | 1.9-2.2 | 166-189 | 2.08-2.37 | 40-48 | 5.0-6.0 | ≤550 | 7.0 | ||

| PAlNiCo40/12 | 0.83-0.90 | 8.3-9.0 | 120-132 | 1.50-1.65 | 124-136 | 1.57-1.71 | 40-44 | 5.0-5.5 | ≤550 | 7.1 | ||

| PAlNiCo45/13 | 0.89-0.91 | 8.9-9.1 | 120-132 | 1.50-1.65 | 126-138 | 1.58-1.73 | 44-50 | 5.5-6.2 | ≤550 | 7.1 | ||

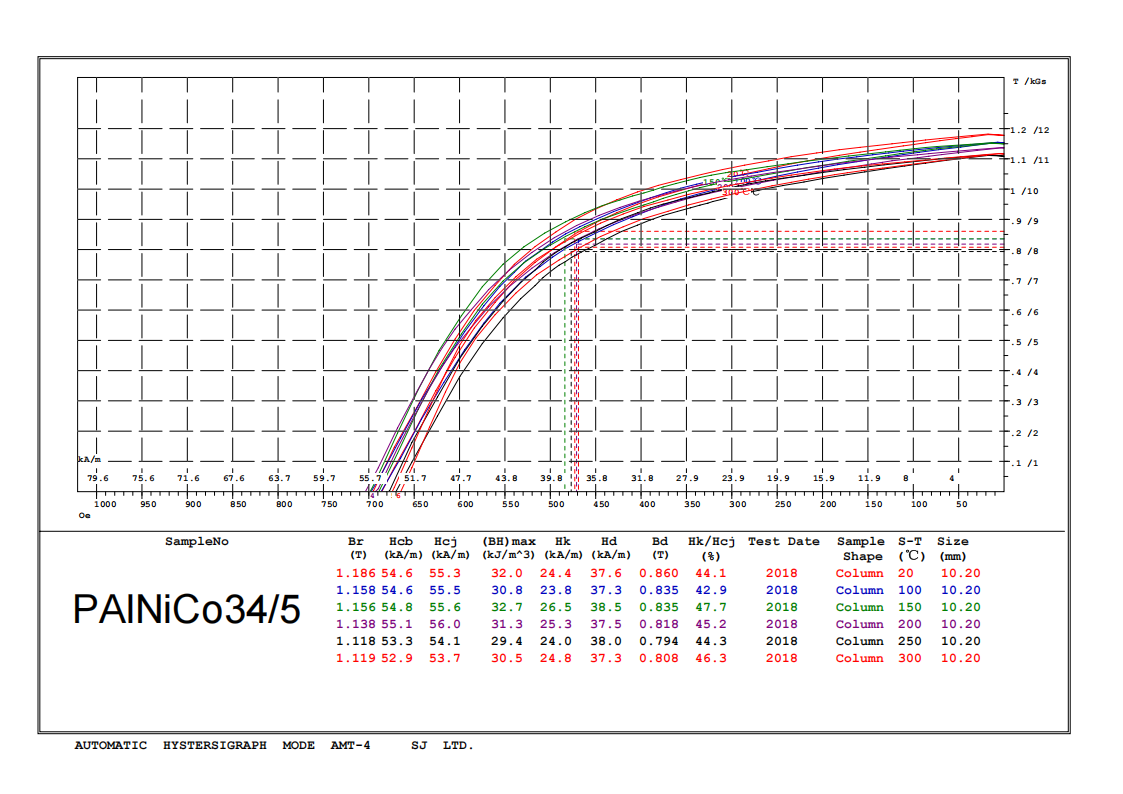

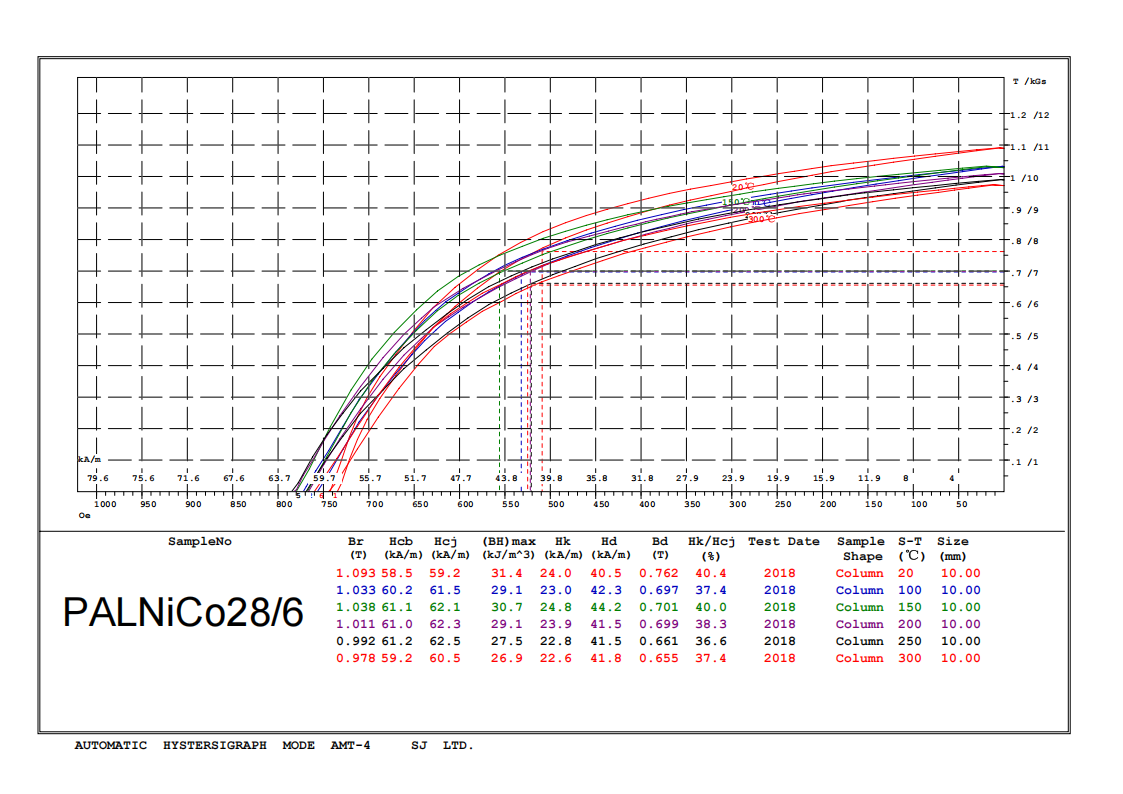

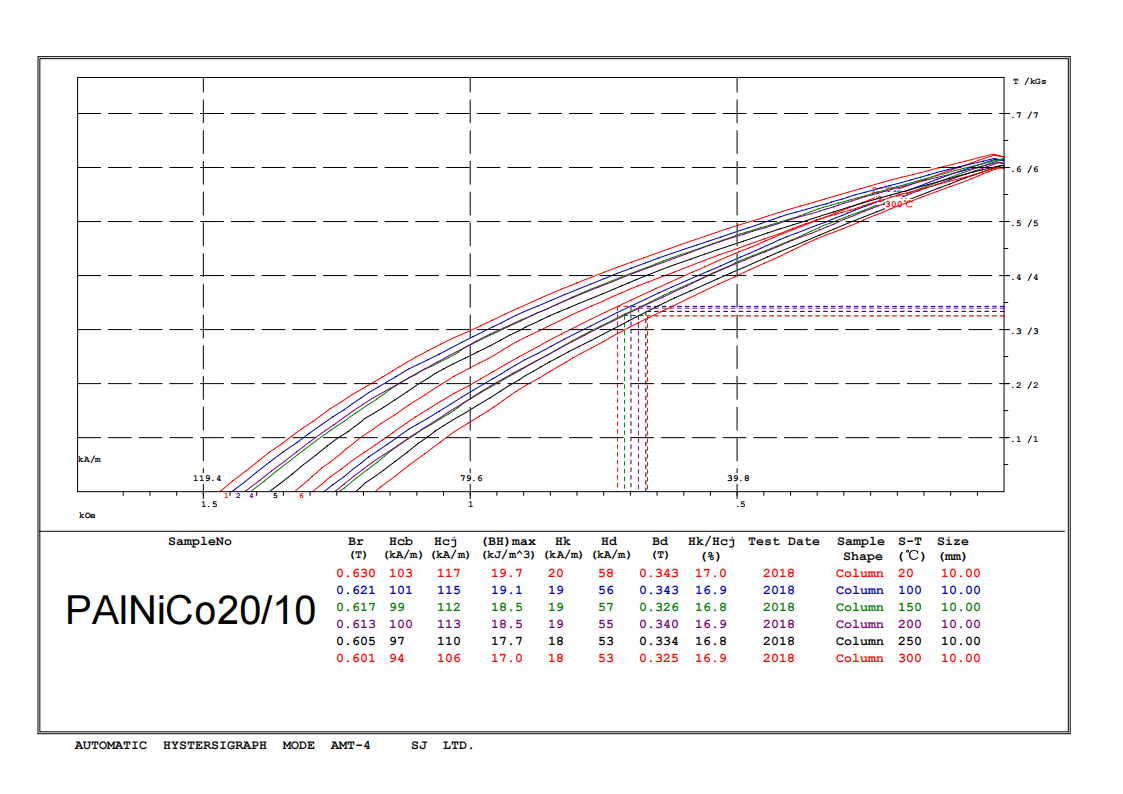

Alnico Magnet Demagnetization Curve

Request a call back?

Ferrite Magnet Performance Table

| Datasheet of Injection Molding Ferrite at Room Temperature | ||||||||||||

| Item | Grade | Remanence induc7on | Coercive force | Intrinsic Coercive force | Maximum Energy product | Working Temperature | Density | temperature coefficient of Br | ||||

| Br | HcB | HcJ | (BH)max | Tw | ρ | α | ||||||

| T | KGs | KA/m | KOe | KA/m | KOe | KJ/m³ | MGOe | ℃ | g/cm3 | %/℃ | ||

| Injec7on Ferrite Magnet | KBI-F1.5 | 0.22~0.24 | 2.2~2.4 | 160~167 | 2.00~2.10 | 231~240 | 2.90~3.00 | 11.6~12.4 | 1.45~1.55 | ≤150 | 3.25 | -0.19 |

| KBI-F1.9 | 0.27~0.29 | 2.7~2.9 | 180~186 | 2.25~2.33 | 216~228 | 2.70~2.85 | 14.8~15.6 | 1.85~1.95 | ≤150 | 3.63 | -0.19 | |

| KBI-F2.0 | 0.28~0.29 | 2.8~2.9 | 184~200 | 2.30~2.50 | 216~246 | 2.70~3.10 | 15.6~16.4 | 1.95~2.05 | ≤150 | 3.7 | -0.19 | |

| KBI-F2.1 | 0.28~0.29 | 2.8~2.9 | 190~204 | 2.38~2.55 | 224~249 | 2.80~3.12 | 16.4~17.2 | 2.05~2.15 | ≤150 | 3.75 | -0.19 | |

| KBI-F1.7(PPS) | 0.25~0.26 | 2.5~2.6 | 167~175 | 2.10~2.20 | 208~216 | 2.60~2.70 | 13.6~14.0 | 1.70~1.75 | ≤180 | 3.65 | -0.19 | |

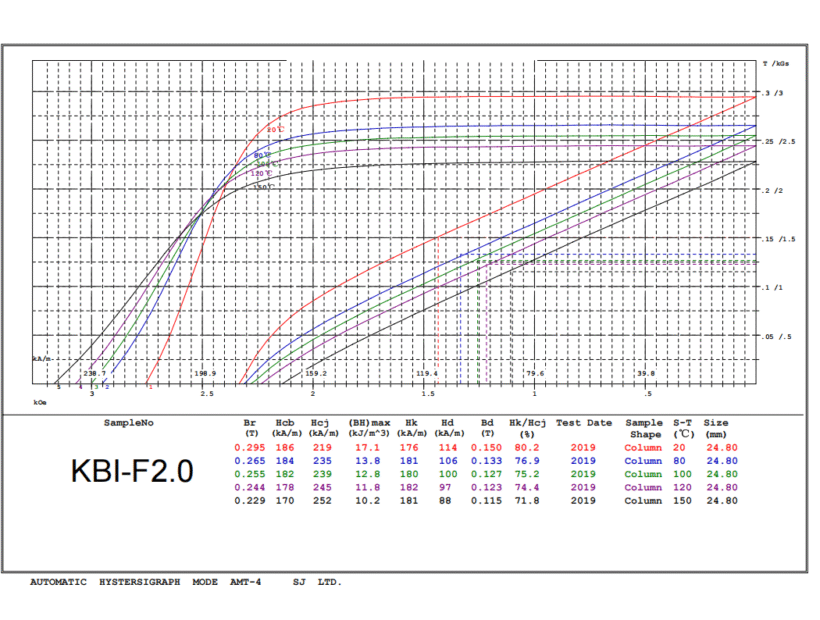

Ferrite Magnet Demagnetization Curve