Ferrite Ceramic Magnets-Ring Shape, Industrial & Motor Magnet丨CORT

ferrite ceramic magnets Product Description

Our ferrite ceramic magnets are magnetic parts made from ferrite magnet material. With PBT + GF15% composition, these ring – shaped magnets are stable. They are customizable for industrial and motor applications. Whether for standard industrial magnet uses or customized motor magnet projects, these ferrite ceramic magnets are consistent and reliable.

ferrite ceramic magnets Specifications

- Material: PBT + GF15% and ferrite magnet core. This composition balances mechanical strength and magnetic properties for long-term use in industrial and motor environments.

- Certification: RoHS and CE certified. Our commitment to environmental safety and product quality ensures compliance with international standards.

- Application: Industrial Magnet and Motor Magnet. They can meet the magnetic force needs in industrial machines and motor-related tasks. This includes providing a stable magnetic field for motors and handling materials in factories.

- Coating: Injection coating. This coating not only increases durability but also provides a smooth surface finish to protect from environmental factors that can affect performance.

- Size: Fixed size 150134.3H28mm (customizable). This standard size fits common industrial and motor magnet application needs while allowing for adjustment based on project requirements.

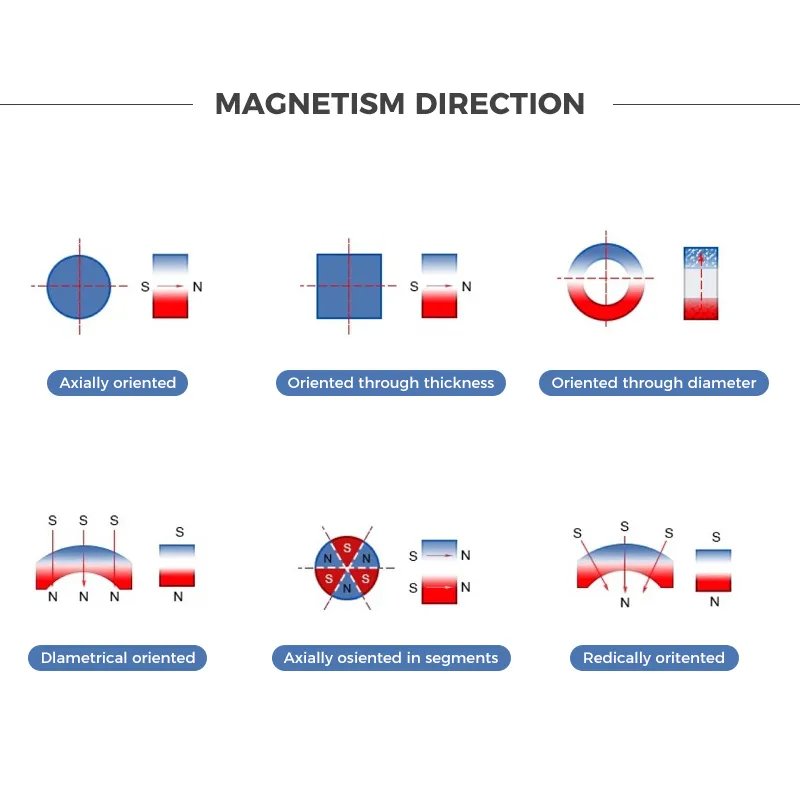

- Shape: Ring shape. A ring shape is good for applications where circular magnetic field distribution is required, such as motor assemblies or certain industrial holding devices.

- Surface Gauss:1700 GS. This magnetic strength is good for material lifting in industrial settings or motor efficiency.

- Operating Temperature: 30 to 120º. This range lets them work in different places, from cold storage to hot motor areas.

ferrite ceramic magnets Features

- Stable: Magnetic>1700 GS, these ferrite ceramic magnets have a stable and sufficient magnetic force. This stability is important for industrial material handling (e.g., lifting ferromagnetic objects) and motor operation (energy conversion).

- Customization: We can customize. Whether you need to adjust the size or specific modification to fit your industrial or motor application, our production can be customized to your needs.

- Certified: RoHS and CE certified. You can trust their safety and reliability in your application, whether in large industrial projects or motor manufacturing.

- Coating: Injection coating gives the magnets a smooth finish and protects them from wear, corrosion, and environmental damage. This extends their life in a harsh industrial environment.

- Wide Operating Temperature Range: From – 30 ºC to 120 ºC, these magnets can perform reliably in diverse conditions. This makes them suitable for use in cold storage facilities, hot industrial plants, and the temperature-varying environments of motor operation.

ferrite ceramic magnets Application Scenarios

Industrial Magnet Applications

Material Handling: In industrial settings, these ferrite ceramic magnets can be used in magnetic lifting devices. With >1700 GS surface gauss, they can lift and move ferromagnetic materials like steel plates or bars, making production and logistics more efficient.

Magnetic Separation: Magnetic separators can remove metal contaminants from industrial fluids. This is important in food processing to keep products pure. It is also used in mining to separate valuable minerals from waste.

Motor Magnet Applications

Motor Assemblies: In electric motors, these ring-shaped ferrite magnets contribute to the magnetic field for motor operation. Their stable magnetic performance and suitable size (150134.3H28mm) will enhance motor efficiency and power output, applicable in household appliances (e.g,. fans, washing machines) and industrial machinery motors.

ferrite ceramic magnets Customization Services

Size and Shape Customization

Process: If the standard 150134.3H28mm size or ring shape doesn’t fit your needs, contact us. We can adjust the size dimensions or even modify the shape (within practical manufacturing limits) by our advanced production techniques.

Applications: For unique industrial setups where non-standard magnet sizes are required, or for motor designs that need custom-shaped magnets for optimal performance.

Coating Customization (if needed, though standard is injection)

Process: While the standard is injection coating, if your application requires a different coating type for specific environmental resistance (e.g., enhanced corrosion protection in extreme industrial environments), we can explore alternative coating solutions. We will work with you to select and apply the most suitable coating.

Applications: For example, in marine-related industrial applications where high salt water corrosion resistance is needed, or in motors operating in highly dusty environments that require extra protection.

ferrite ceramic magnets Quality Assurance

Certification Compliance: Our ferrite magnetics are produced in accordance with RoHS and CE standards. This means they are free from hazardous substances (RoHS) and meet European safety, health, and environmental protection requirements (CE).

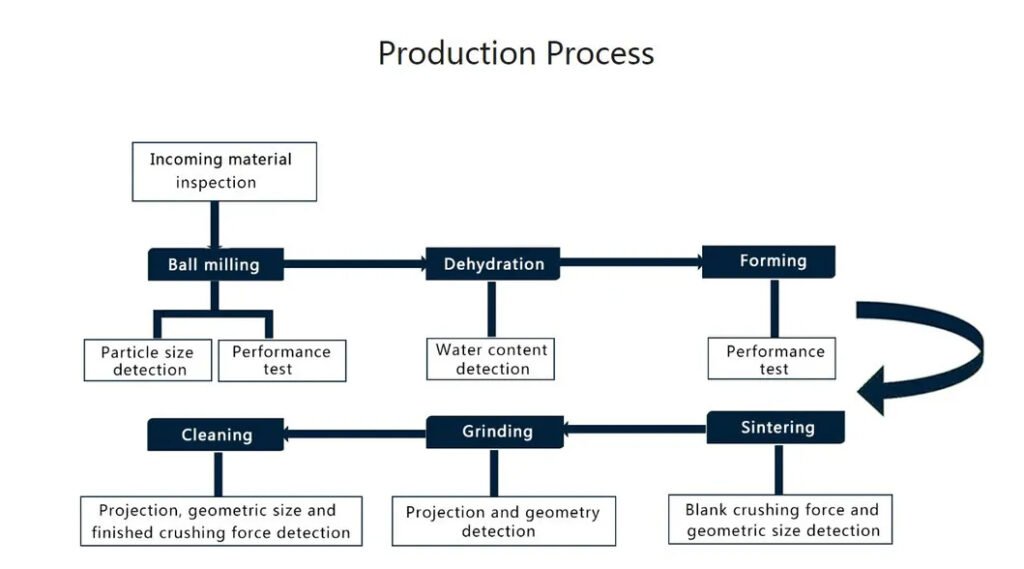

Quality Control Process: Raw Material Inspection: We source PBT + GF15% and ferrite magnet materials from reliable suppliers. Each batch of raw materials undergoes strict inspection to ensure it meets our quality standards for composition and performance.* Production Inspection: Our quality control team inspects every step of the production process, from molding to coating. So the magnets are formed correctly, have the right size, and the coating is applied evenly and correctly.

Final Inspection: Before shipping, all magnets are inspected again. This includes surface gauss strength, size tolerance, coating integrity and operating temperature, and certification requirements. Only magnets that pass all these checks are shipped out.

ferrite ceramic magnets Ordering and Delivery

Ordering Process

Inquiry: Reach out to our sales team via email, phone, or our official website. Provide details such as your required quantity, any customization needs (size, shape, coating), and the specific application (industrial or motor magnet use).

Quotation: Based on your inquiry, we will prepare a detailed quotation, including product price, delivery time, and any additional service costs (e.g., for customization).

Sample Order (Optional): If you want to test the product before placing a large-scale order, we can produce a sample for you. This allows you to verify the quality, performance, and suitability of our ferrite ceramic magnets for your application.

Bulk Order: Once you are satisfied with the sample (or if you choose to skip the sample stage), you can place your bulk order. We will confirm the order details, including delivery schedule and payment terms, and then start the production process.

Delivery: We offer global shipping options to ensure your order reaches you on time, regardless of your location. Our shipping partners are experienced and reliable, providing tracking information so you can monitor the shipment’s progress.

To prevent damage during transit, our ferrite ceramic magnets are carefully packaged. The packaging is designed to protect the magnets from physical impact, moisture, and other potential hazards, ensuring they arrive in perfect condition.

Frequently Asked Questions—ferrite ceramic magnets

1.Can the size of these ferrite ceramic magnets be changed?

Yes, we offer customization services for size. If the standard 150134.3H28mm size doesn’t fit your application, contact our sales team to discuss your specific size requirements.

2. What is the maximum operating temperature again?

These ferrite ceramic magnets can operate within a temperature range of – 30 ~ 120 ºC. This covers most industrial and motor application environments, but if your application involves extreme temperatures beyond this range, let us know and we can explore alternative solutions.

3. Are these magnets suitable for outdoor industrial use?

Yes, with the injection coating providing protection against environmental factors like moisture and minor corrosion. However, for extremely harsh outdoor conditions (e.g., constant heavy rain, salt – water exposure), we may recommend additional coating customizations. Our team can advise on the best solution for your specific outdoor application.

4. How do I know if these magnets are certified?

Our ferrite ceramic magnets come with RoHS and CE certifications. We can provide certification documents upon request during the ordering process, so you can verify their compliance with international standards.

5. What is the lead time for a custom - sized order?

The lead time depends on the complexity of the customization and the order quantity. For small to medium – sized custom orders, it usually takes around 2 – 4 weeks. For large – volume or highly complex custom orders, the lead time may be longer. We will provide you with an accurate estimate during the quotation process based on your specific requirements.