In modern technological products such as smartphones, electric vehicles, and wind turbines, permanent magnetic materials are indispensable core components. Right now, most high-performance permanent magnets depend on rare earth elements. This problem is getting worse as global competition for these resources increases. In this context, a traditional magnetic material called Alnico Magnet is becoming popular again. This material was created nearly a century ago and is now a focus of research in materials science.

Alnico magnets are made of aluminum (Al), nickel (Ni), cobalt (Co), and iron (Fe). They may also include other elements like copper (Cu) and titanium (Ti). They possess unique advantages: high remanence (up to 1.4T), excellent temperature stability (Curie temperature exceeding 800°C), and extremely low temperature coefficients. These characteristics make them irreplaceable in critical fields such as aerospace precision instruments and high-end sensors.

CORT MAGNETS is a Chinese enterprise integrating R&D, production, and sales, expecting to provide one-stop magnetic material solutions for global customers. You can visit our homepage to see the specific information. In addition, we also offer a wide range of sales plans for customers around the world. If you need any assistance, please feel free to contact us at any time.

Table of Contents

A Century of Alnico Magnets Evolution

1.1 Historical Milestones

Alnico Magnets’ development journey epitomizes the evolution of magnetic materials. In 1931, Japanese scholar Tokushichi Mishima discovered that Fe-Ni-Al alloys have magnetic properties. This finding laid the groundwork for Alnico Magnets materials. In 1938, British researcher Oliver added cobalt and copper to this foundation. He officially named the material “Alnico Magnets.” This marked the official start of this material category.

The 1960s were Alnico’s golden age. During this time, they created an alloy system. This system used Fe, Co, Al, and Ni as the main elements. It was divided into several series based on cobalt content. However, the arrival of neodymium-iron-boron (NdFeB) permanent magnets in the 1980s changed everything. Their higher energy product quickly took over the market. This shift caused Alnico magnets research to decline.

1.2 Return to the Center Stage

After 2000, two main factors helped revive Alnico research. First, there was a growing need for stable magnetic materials in precision instruments. Second, the global rare earth resource crisis pushed researchers to find alternatives that do not use rare earth elements. As a typical representative of rare-earth-free permanent magnetic materials, Alnico regained significant attention from academia and industry.

Alnico Magnets: "Nano-Chessboard" Structure

2.1 Spinodal Decomposition: Nature's Nanoscale Engineer

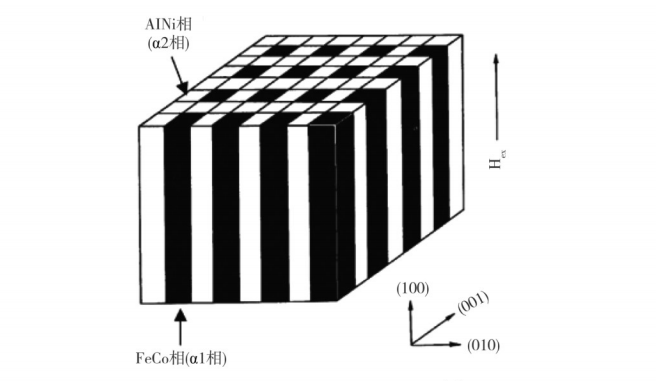

Alnico Magnets’ most unique microstructure arises from a solid-state phase transformation process called “spinodal decomposition.” When the material is treated at high temperatures, it forms a single α-phase solid solution. As it cools in an external magnetic field, this phase breaks down into two nanoscale phases. These phases have body-centered cubic (BCC) structures. The first phase is a magnetic Fe-Co-rich phase, called the α1 phase. The second phase is a weakly magnetic Al-Ni-rich phase, known as the α2 phase.

The structure created by this decomposition process is described by scientists as an “international chessboard” shape. In a plane that is perpendicular to the magnetic field, magnetic phase particles are spread out in the matrix. In the plane that is parallel to the magnetic field, the two phases alternate. This creates a long, repeating structure. This structure is the source of Alnico’s excellent magnetic properties.

2.2 Alnico Magnets Microstructural Differences Among Grades

Studies have revealed significant microstructural differences among different Alnico grades. If you want to know the result of the comparison between alnico 2 and alnico 5, you can check out another article of mine

Alnico 5-7 has less cobalt, around 24-25%. It has a slower spinodal decomposition rate. This leads to larger magnetic phase particles. These particles have an aspect ratio of about 1-5.

Alnico 8: Increased cobalt content (32-36%), forming a “mosaic” structure with small rectangular magnetic phases and increased aspect ratio

Alnico 9 has more cobalt and titanium. Its structure is closer to the ideal chessboard pattern. The magnetic phase aspect ratios are over 10. It also has a more even distribution

These structural differences directly lead to performance variations: Alnico 9 possesses the highest energy product (7.4 MGOe) due to its ideal microstructure, making it representative of high-performance Alnico.

2.3 Alnico Magnets: Mysterious Cu-Rich Phase

In recent years, advanced characterization techniques have revealed another critical structure in Alnico—the presence of Cu-rich phases. These tiny copper-enriched phases are about 3-5 nm wide. They mainly sit at the edges of magnetic and matrix phases. They act like small “nails” that hold domain walls in place. This stops domain wall movement and increases the material’s coercivity.

Research shows that forming Cu-rich phases is a dynamic process. It starts with small Cu-Ni atomic clusters. These clusters gradually grow into rod-like shapes. Eventually, they form a network distribution. This discovery provides a new approach for enhancing Alnico performance through composition optimization.

Breaking the Coercivity Bottleneck

3.1 Alnico Magnets: Coercivity Challenge

Despite Alnico Magnets’ many advantages, their coercivity (Hc) is much lower than expected. This limits its performance. Traditional theory says that magnetization reversal in Alnico follows the “coherent rotation model.” However, actual measurements show that coercivity is 30-50% lower than theoretical values.

Recent studies combining micromagnetic simulations and advanced characterization have revealed the source of this discrepancy: structural defects, phase interface roughness, and composition fluctuations in real materials facilitate domain wall movement, thereby reducing coercivity.

3.2 Enhancement Strategies

In recent years, researchers have primarily pursued two approaches to break through the coercivity bottleneck:

(1)Alloying Optimization:

- Appropriate Ti addition to promote Cu-rich phase formation and distribution uniformity

- Adjusting Co content to control spinodal decomposition rate and magnetic phase morphology

- Introducing trace elements like Nb to refine grain structure

(2)Process Innovation:

- Optimizing magnetic field heat treatment parameters to improve magnetic phase orientation

- Developing stepwise tempering processes for precise control of phase transformation

- Exploring magnetic field-assisted sintering to improve magnetic phase alignment

These measures have achieved significant results, with coercivity in some laboratory samples increasing from 0.6 kOe (traditional Alnico 5) to over 2 kOe.

3.3 The Secret of Temperature Stability

Another major advantage of Alnico Magnets is their excellent temperature stability. Its temperature coefficient of magnetic properties is much lower than other permanent magnetic materials, stemming from:

- High Curie temperature (800-860°C), far exceeding NdFeB (310-400°C).

- Minimal temperature variation of the unique spinodal structure.

- Ordered structure of α2 phase (B2 or L21 type) providing additional thermal stability.

Alnico Magnets: From Traditional Casting to Advanced Processes

4.1 Mature Casting Technology

Currently, Alnico magnets are primarily produced industrially using casting methods:

- Vacuum melting of alloys

- Sand or permanent mold casting

- Magnetic field heat treatment

- Multi-stage tempering

This process is mature and reliable, suitable for large-scale production, but cannot easily produce complex shapes or thin-walled magnets, limiting Alnico’s application range.

4.2 Advanced Preparation Technologies

To overcome the limitations of traditional processes, researchers have developed various advanced preparation technologies in recent years:

(1)Near-Net Shape Technologies:

- Powder metallurgy: Enabling complex-shaped magnets through powder compaction and sintering

- Injection molding: Achieving mass production of high-precision, complex-shaped components

(2)Rapid Solidification Technologies:

- Melt spinning: Obtaining finer, more uniform microstructures through rapid cooling

- Atomization powder production: Preparing nanocrystalline powders to enhance magnetic properties

(3)3D Printing Technologies:

- Selective laser melting: Directly forming complex three-dimensional structures with high material utilization

These new technologies not only expand Alnico’s application possibilities but also enable further magnetic property enhancement through microstructure control.

Alnico Magnets: Application Prospects and Challenges

5.1 Core Application Areas

Alnico Magnets occupies irreplaceable positions in the following fields due to its unique properties:

- Aerospace: Inertial navigation systems, attitude sensors, precision instruments

- High-end Manufacturing: Servo motors, torque sensors, magnetic encoders

- Medical Equipment: MRI devices, precision medical instruments

- Energy Sector: Sensors and actuators in high-temperature environments

5.2 Facing Challenges

Despite promising prospects, Alnico Magnets still faces numerous challenges:

- Insufficient coercivity: Gap compared to NdFeB limits applications in miniaturized devices

- Cost issues: High Co content results in elevated raw material costs

- Manufacturing complexity: Industrialization of advanced preparation technologies remains difficult

- Performance stability: Batch-to-batch performance fluctuations require further control

5.3 Future Research Directions

Addressing these challenges, future research will focus on:

- Deepening understanding of spinodal decomposition mechanisms to achieve precise structural control

- Developing new alloy systems to balance coercivity and remanence

- Promoting industrial application of advanced preparation technologies

- Expanding applications in new energy and intelligent manufacturing fields

Contact us for a free sample

Alnico Magnets: A New Star of Magnetic Materials

Alnico Magnets’ magnetic materials are experiencing growth. This is happening because there is a higher global demand for rare earth resources and advanced manufacturing. From their discovery in the 1930s to today’s control of nanoscale structures, Alnico has come a long way. Each step in its development shows how materials science and engineering work together in new ways.

As research and technology improve, Alnico Magnets are likely to replace rare-earth permanent magnets in more areas. This will create new opportunities for developing magnetic materials that do not use rare earth elements. For materials scientists and engineers, Alnico is more than just a useful material. It is a great model for understanding how solid-state phase changes, microstructures, and large-scale properties are related.

In today’s quest for sustainable development, the revival of Alnico permanent magnets is very important. It also brings hope for a greener manufacturing process. In the future, this century-old material will undoubtedly shine more brilliantly in the new era.