Customized Services

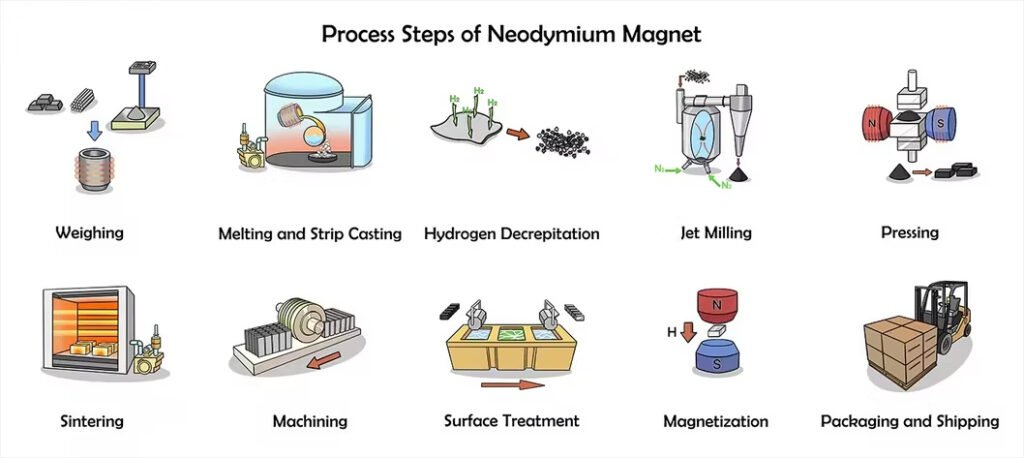

Every project is unique, and off-the-shelf magnets may not always meet your needs. That’s where our custom services shine. We provide complete solutions for custom magnets, from material selection to delivery. Our team works closely with you to understand your specific requirements – whether it’s adjusting magnetic strength, size, and shape or compatibility with extreme environments. We deliver high-quality custom magnets that exceed your expectations.

Industrial applications of magnets

Industrial applications of magnets

Consumer Electronics

Mini Motor

Renewable Energy

Industrial Machinery

Medical Equipment

Aviation Accessories

Wireless Charger

and more

Our magnet customization options

Our magnet customization options

Custom Magnet Types

- For high-end applications, N52 NdFeB powers EV motors, enabling them to produce high torque in compact sizes.

- For tough environments: Alnico magnets (Grade 8) handle temperatures over 600℃, made just for aerospace engine sensors.

- For saving costs, Ferrite magnets meet large-scale needs (like in home appliances and toys) with steady performance.

- Our material engineers study your application closely to pick the right magnet type and specs – no sacrifices on performance or budget.

Custom Magnet Grades

- In Renewable Energy: N52SH for wind turbines loses less than 3% of flux between – 40℃ and 150℃.

- In Industrial Machinery: N48UH stands up to over 100,000 shocks and keeps flux stable.

- In Medical Equipment: N38M meets MRI’s needs for low hysteresis and high consistency.

- Using magnetic simulation and testing prototypes, we make sure the grade fits your device’s conditions perfectly.

Custom Magnet Shapes

- In Consumer Electronics: Curved magnetic hinges for foldable phones work for over 300,000 folds without coming loose.

- In Robotics: Trapezoidal magnets for joints boost torque by 22%.

- In Automotive: Multi-hole magnets for motors raise power density by 15%.

- We go from your concept drawing to a working sample in 72 hours – your new ideas won’t be held back by manufacturing.

Custom Magnet Sizes

- Tiny Magnets: ±0.01mm tolerance, perfect for small wearables.

- Large Magnets: ±0.1mm precision, keeping industrial loads stable.

- An AI-powered inspection line checks 10% of each batch with 3D imaging. Your production line gets magnets that work right away, with no setup costs.

Custom Magnet Coatings

- Functional Coatings:

- Ni – Cu – Ni passes 1,000 – hour salt – spray tests, good for marine and automotive undercarriages.

- Epoxy coating gives 1,000V insulation, made for electronic components.

- Brand – Match Coatings:

- Custom – colored Zinc (like matte black, anodized blue) for consumer tech that looks good and works well.

- Our direct – to – substrate plating bonds coatings at a molecular level, keeping over 99.5% of flux (checked by third parties). No trade-off between protection and magnet strength.

Additional Customizations

- Component Integration: We combine magnets with metal or plastic parts to make “ready-to-install” sub – sub-sub-sub-sub-assemblies (like EV charging port magnetic modules).

- Magnetic Simulation: We use 3D models to optimize flux distribution early (like “zero-leakage” for medical devices).

- Packaging Customization:

- Factory-Ready: Trays and magnetically safe materials for automated lines.

- Retail – Ready: Color boxes and manuals for direct – to – consumer brands.

- Rapid Prototyping: We deliver working samples in 5–7 days, with material certificates and performance data, speeding up your R&D.

From buying single parts to getting complete solutions, we help you simplify supply chains and cut hidden costs.

RECENT CUSTOMIZED PROJECTS

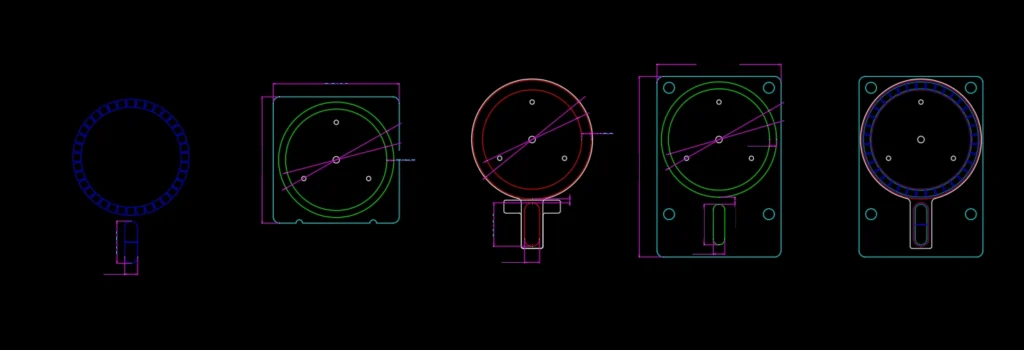

Wireless Charging Magnetic Ring Customized Project

Magnet material: N35 neodymium iron boron. N35 means the maximum magnetic energy product of this neodymium iron boron magnet is between 33 and 36 MGOe, high magnetic performance, meeting the magnetic force requirements of wireless charging.

Additional iron sheet: Add an iron sheet with 0.7mm thickness to enhance magnetism or adjust the magnetic field distribution, to meet the specific electromagnetic performance requirements of wireless charging.

Myra material: Pure white Myra (polyethylene terephthalate film) is used, can be used for insulation, to protect the surface of the magnet, or to beautify the appearance.

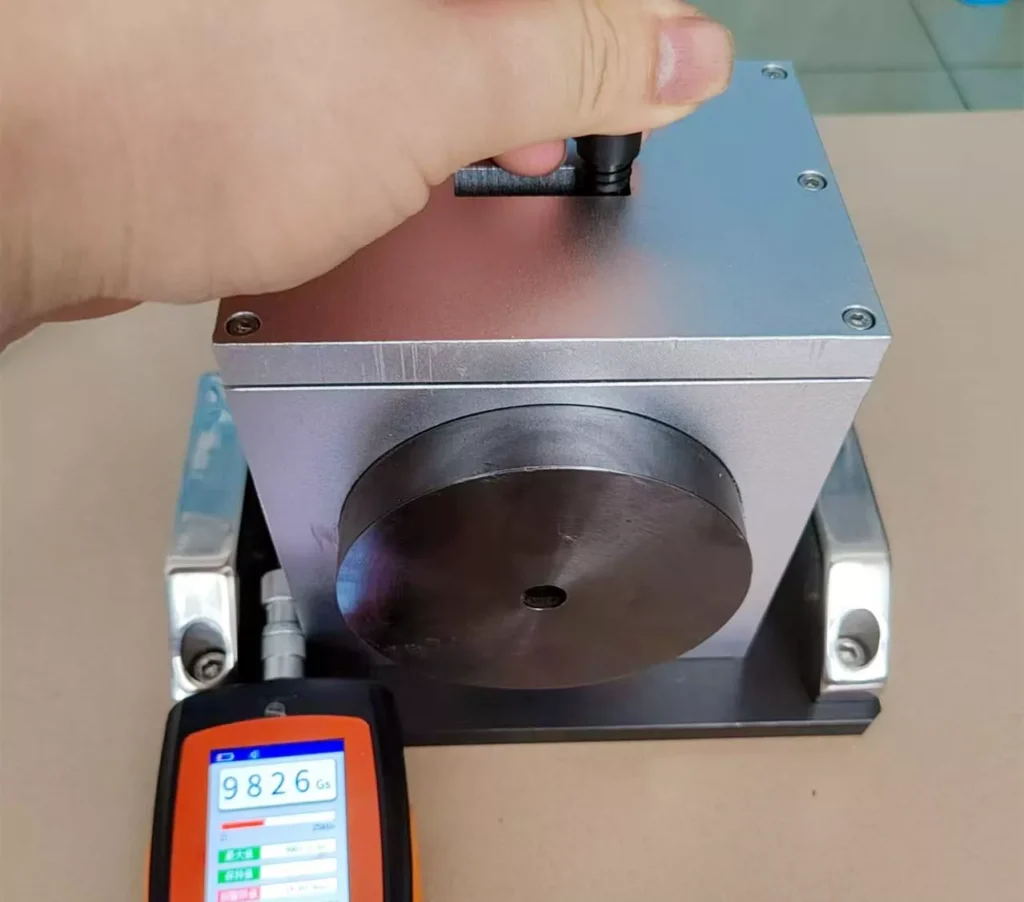

neodymium magnets Customized Project

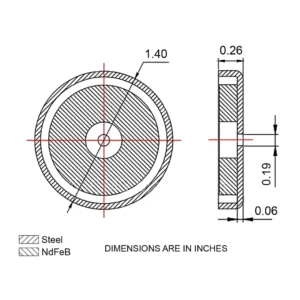

This circular perforated magnet is made of neodymium iron boron (NdFeB) and steel. Neodymium iron boron is the core material, providing the magnetism, and steel is for structural strength and magnetic conduction.

Diameter: 1.40 inches. Thickness varies in different areas: edge is 0.06 inches, middle is 0.19 inches, and total height is 0.26 inches. There is a through hole in the center for easy installation and fixation with screws or other connecting components.

ferrite magnets Customized Project

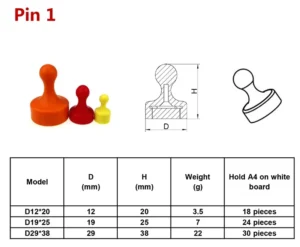

Product is a ferrite material drawing pin, overall shape is like a traditional drawing pin. Upper part is round head for easy grip, lower part is the base for adhesion.

There are three specifications and models:

– Model D1220: D=12mm, H=20mm, 3.5g

– Model D1925: D=19mm, H=25mm, 7g

– Model D2938: D=29mm, H=38mm, 22g

Each model weight is different.

Experience CORT's Excellence Today!

Whether you’re a consumer electronics brand, automotive manufacturer, industrial equipment provider, or a buyer in the renewable energy sector, choosing CORT Magnet means choosing high-performance, customized magnetic solutions for your projects. Contact us to learn more, or get a free quote today to boost the performance of your products!