I am Aaron Chen, the operations director of CORT MAGNET. CORT MAGNET is a manufacturer specializing in the research and development of magnetic materials. It has over 15 years of experience in the research and development of magnetic materials, as well as international sales experience.I will analyze Cylinder Magnets vs Disc Magnets from the perspective of a magnet manufacturer, and determine which one would be more suitable for your project. Of course, as time goes by, perhaps in the future, there will be changes. However, if you can understand the principles of Cylinder Magnets and Disc Magnets from this article, I believe that in the future, you will also be able to make correct judgments.

Cylinder magnets vs disc magnets is a question we hear daily from engineers and buyers who want the best performance per dollar. Both shapes can be made from NdFeB (neodymium), ferrite, SmCo, or AlNiCo, yet their geometry drives very different field patterns, assembly methods, and lifetime costs. This guide compares them head-to-head with clear selection rules, application tips, and sourcing advice from the CORT MAGNET team.

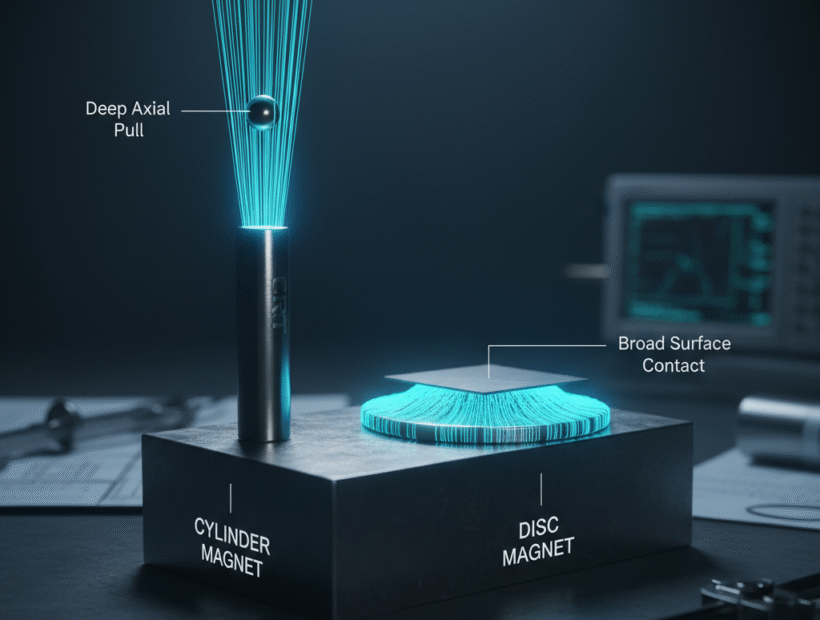

Quick verdict: choose cylinder magnets when you need deep, focused axial pull or a “reach” into a bore. Choose disc magnets when you need broad surface contact and a uniform field over a flat interface.

Table of Contents

What is a cylindrical magnet?

A cylindrical (rod) magnet has a round cross-section with length ≥ diameter. Most are axially magnetized (N/S on the flat ends), concentrating flux at the circular faces for a strong, localized pull. This makes cylinders excellent for insertion into housings, linear actuators, latches, and fixtures where you have depth but a limited footprint. If required, cylinders can be diametrically magnetized for rotating couplings and sensors.

- Typical coatings: Ni-Cu-Ni, Zn, epoxy, or passivated, depending on environment and assembly method

- Tolerances: ±0.05–0.10 mm are common in precision applications

Helpful CORT resources:

Cylinder Magnets vs Disc Magnets: fast comparison

| Feature | Cylinder Magnets | Disc Magnets |

|---|---|---|

| Geometry | Length (L) ≥ diameter (D) | Thickness (T) ≪ diameter (D) |

| Field pattern | Focused at circular ends → deeper axial reach | Spreads across flat face → high face pressure |

| Best for | Insertion into bores, linear motion, latching with depth | Flush mounting, panel holding, couplings on flat surfaces |

| Assembly | Press-fit, adhesive in bores, set-screw retainers | Surface adhesive, countersunk discs, tape or carriers |

| Heat options | SmCo/AlNiCo versions for higher temps | SmCo/ferrite discs for cost-effective heat resistance |

| Cost drivers | Length, grade, grinding | Diameter, thickness, grade, plating |

| Stockability | Often custom length; easy to stack | Many off-the-shelf diameters & thicknesses |

You’ll see cylinder magnets vs disc magnets tradeoffs most clearly in how the working gap behaves: cylinders maintain pull deeper into a gap; discs excel when the gap is near-zero and area contact is large.

Why choose cylinder magnets?

Q: When do cylinders outperform discs?

- Deep axial pull or “reach”: Need force at 2–6 mm standoff? Cylinders retain more usable flux along the axis than thin discs.

- Bore or pocket installs: The round profile and length allow secure press-fits and anti-shear retention.

- Sensors & motion: Hall sensors, reed switches, and linear slides benefit from the directional, concentrated field.

- Stackability: You can stack cylinders to tune force or trigger distance with repeatable increments.

- Rotational stability: Long aspect ratio helps alignment in couplings and magnetic bearings.

Browse examples:

Why choose disc magnets?

Q: When do discs beat cylinders?

- Face-to-face clamping: Flat-panel attachment, signage, tool plates, and closures love the wide contact area.

- Low profile: Discs minimize Z-height and integrate under labels, gaskets, or thin skins.

- Uniform field on planes: Better for couplings that rely on face area rather than depth.

- Convenience: Discs are widely stocked in many diameters and thicknesses, simplifying procurement.

How are cylinder magnets made?

Q: What does the manufacturing flow look like?

Powder metallurgy (for NdFeB/SmCo) → pressing with field alignment → sintering → heat-treat → precision grinding (OD/length) → coating → magnetization (axial or diametric) → inspection (flux, Br/Hcj, dimensional). Cast or sintered AlNiCo cylinders are also common for high-stability applications and can be ground or turned to tight tolerances.

Do cylindrical magnets have only one pole?

No—magnetic monopoles have not been observed. Every permanent magnet, cylinder or disc, has North and South. The practical question is pole location:

- Axial magnetization: poles on the flat ends (most common).

- Diametric magnetization: poles on the curved side, 180° apart—useful for certain couplings and sensor triggers.

What’s the difference between a bar magnet and a cylindrical magnet?

Bars are rectangular; cylinders are round. With equal volume and grade, shape changes the field distribution:

- Cylinders: concentrated axial field—great for deep pull, bores, and linear motion.

- Discs: flat and round—best for face-clamping on planar surfaces.

Application playbook: choose by requirement

Q: How do I decide—cylinder magnets vs disc magnets—for my exact requirement?

- Holding & fixturing

- Flush mount on a plate/panel: pick disc magnets (larger diameter, thin T).

- Inside a hole or bushing: pick cylinder magnets (L ≥ D, axial).

- Shear loads: cylinders in pockets resist shear better than surface-mounted discs.

- Sensing & actuation

- Reed/Hall trigger at distance: cylinders maintain field at standoff.

- Face-coupled triggers with near-zero gap: discs are simpler and lower profile.

- Diametric effects: for rotary sensing, a diametrically magnetized cylinder gives clean angular transitions.

- Motors, couplings, and motion

- Linear actuators and solenoids: cylinders concentrate flux along travel.

- Magnetic couplings on flat faces: discs, often in pairs or arrays.

- High temperature: consider SmCo or AlNiCo versions (available as both cylinders and discs).

- Size, cost, and supply

- Cost priority: ferrite discs are often the value leader.

- Force per volume: NdFeB cylinders or discs (N35–N52) deliver top energy density.

- Customization: CORT supports tight tolerances, special coatings, and magnetization directions across both shapes. Start here: Customized Service.

Engineer’s checklist (copy/paste)

When you send a spec or RFQ, include:

- Shape & size: Cylinder (Ø×L) or Disc (Ø×T)

- Grade & temp: NdFeB Nxx (or SmCo/AlNiCo/Ferrite) + max operating temp

- Magnetization: Axial or diametric; orientation to datum

- Coating: Ni-Cu-Ni, Zn, Epoxy, Au, etc.

- Tolerance: e.g., OD ±0.05 mm, length ±0.10 mm

- Mating material: steel grade, thickness, air gap

- Environment: humidity, salt fog, sterilization, chemicals

- Packaging & compliance: RoHS/REACH, SGS/CE, labeling

You can reference typical ranges here: Magnet Size Range.

FAQs about cylinder magnets vs disc magnets

Where are cylinder magnets used most?

- Motors & linear motion: rotors, sliders, voice-coil drives

- Industrial fixtures: latches, chucks, pick-and-place nests

- Electronics: haptics, micro-speakers, camera modules.

Can discs ever replace cylinders?

- Yes—if you can bring the magnet flush to the mating surface and maximize diameter, discs often achieve equal or better holding force at lower thickness and cost.

What if I need high temperature?

- Pick SmCo or AlNiCo in either shape. Example: High-Performance AlNiCo.

How do I prevent corrosion?

- Select the right coating (Ni-Cu-Ni, epoxy, etc.) and seal adhesive joints. Our team can advise per environment: Contact CORT.

Decision guide: which is better for your project?

- To make cylinder magnets vs disc magnets concrete, apply these rules:

- Choose a cylinder magnet if… you need force through a gap or into a bore, want stable alignment in a pocket, or must tune trigger distance by stacking.

- Choose a disc magnet if… you can maximize contact area on flat parts, need low profile, or prefer widely stocked sizes for quick builds.

If you’re still unsure, send us Ø/length (or Ø/Thickness), target pull at a stated air gap, and your base steel thickness. CORT engineers will simulate options and recommend geometry and grade that minimize BOM cost while hitting force and temperature targets.Explore more insights on our Blog or jump straight to Neodymium Magnets (Category).

From quick prototypes to volume production, we design, grind, coat, magnetize, and test to spec. Start with a drawing or even a sketch—our team will optimize geometry and grade for your budget and operating environment.

If your design needs depth, pocket installs, or gap tolerance, choose cylinder magnets. If it needs low profile and broad face contact, choose disc magnets. When in doubt, send CORT your dimensions, gap, and temperature—we’ll specify the optimal shape, grade, and coating.

Update Date: September 18, 2025

Contact Channel: Contact Us (Whatsapp: +8619118612939)

Disclaimer: Please note that the content of this article is solely derived from the personal perspective of CORT MAGNET and combined with industry analysis. It is provided for explanatory purposes only. If any issues arise, please contact us.

Contact Channel: Contact Us (Whatsapp: +8619118612939)

Disclaimer: Please note that the content of this article is solely derived from the personal perspective of CORT MAGNET and combined with industry analysis. It is provided for explanatory purposes only. If any issues arise, please contact us.