Ferrite magnets, often called ceramic magnets, are permanent magnets made from a mix of iron oxide and either barium or strontium. These magnets stand out because they are ferrimagnetic, ceramic in nature, non-conductive, and highly resistant to demagnetization. Ferrite magnets account for over 70% of the global permanent magnet market by volume, driven by their cost-effectiveness and reliability. The table below highlights what makes ferrite and ceramic magnets unique:

Characteristic | Description |

|---|---|

Ceramic magnets do not conduct electricity. | |

Corrosion Resistance | They resist rust and moisture, even in harsh environments. |

Temperature Stability | Ferrite magnets work well from -40°C to +300°C and resist demagnetization. |

Table of Contents

Key Takeaways

Ferrite magnets are ceramic magnets made from iron oxide combined with barium or strontium, offering strong corrosion resistance and electrical insulation.

They come in two types: isotropic magnets with random magnetic domains and anisotropic magnets with aligned domains, the latter providing stronger magnetic force.

Ferrite magnets work through ferrimagnetism, where opposing atomic magnetic moments create a net magnetic field, allowing them to retain permanent magnetism.

These magnets are cost-effective, stable at high temperatures up to about 250°C, and resist rust, making them ideal for electronics, household items, automotive parts, and industrial uses.

Their ceramic nature makes ferrite magnets hard but brittle, so they require careful handling to avoid chipping or breaking under mechanical stress.

Compared to rare earth magnets, ferrite magnets have lower magnetic strength but offer better corrosion resistance and a much lower environmental impact.

Ferrite magnets provide excellent electrical insulation, reducing energy loss and electromagnetic interference in high-frequency electronic devices.

Advances in technology and AI have improved ferrite magnet performance, expanding their use in modern applications like electric vehicles and renewable energy.

Ferrite Magnets: Composition

Materials

Iron Oxide

Ferrite magnets use iron oxide as their main ingredient. This iron oxide, often in the form of hematite or magnetite, combines with other metal oxides to create a strong magnetic material. The iron oxide gives ferrite its ceramic nature, which makes these magnets non-conductive and highly resistant to corrosion. The crystal structure of ferrite, known as spinel, forms when iron oxide mixes with divalent metal ions. This structure helps reduce eddy current losses, making ferrite magnets ideal for high-frequency applications.

Barium and Strontium

Manufacturers often add barium or strontium to the iron oxide powder to produce ceramic magnets. These elements act as the divalent metal ions in the ferrite formula, which is generally written as MFe2O4, where M stands for a metal like barium or strontium. The choice of metal ions affects the magnetic hardness and electrical resistance of the final product. For example, cobalt ferrite creates a magnetically hard material, while nickel-zinc ferrite results in a softer magnetic material. The combination of iron oxide with barium or strontium produces a powder that, when pressed and heated, forms the finished ferrite magnet.

Note: The chemical composition of ferrite magnets directly influences their magnetic strength, resistance to demagnetization, and suitability for different uses.

Ferrite Magnets Structure

Ferrite magnets have a unique ceramic microstructure. Unlike metallic magnets, such as neodymium or AlNiCo, ferrite magnets consist of iron and oxygen atoms arranged in a ceramic matrix. This structure gives them strong corrosion resistance and high temperature stability. The table below compares the microscopic structure of ferrite magnets with other common types:

Magnet Type | Microscopic Structure | Composition | Key Microscopic Difference | Resulting Properties |

|---|---|---|---|---|

Ferrite Magnets | Ceramic microstructure | Iron + Oxygen (ceramic ferrite) | Ceramic nature with iron oxide matrix | Strong corrosion resistance, high temperature resistance |

NdFeB Magnets | Metallic microstructure | Rare earth alloys (Neodymium, Iron, Boron) | Complex metallic alloy with rare earth elements | Stronger magnetic properties, poor corrosion resistance |

AlNiCo Magnets | Metallic microstructure | Metal alloys (Aluminum, Nickel, Cobalt) | Metallic alloy structure | Strong magnetic force, more expensive |

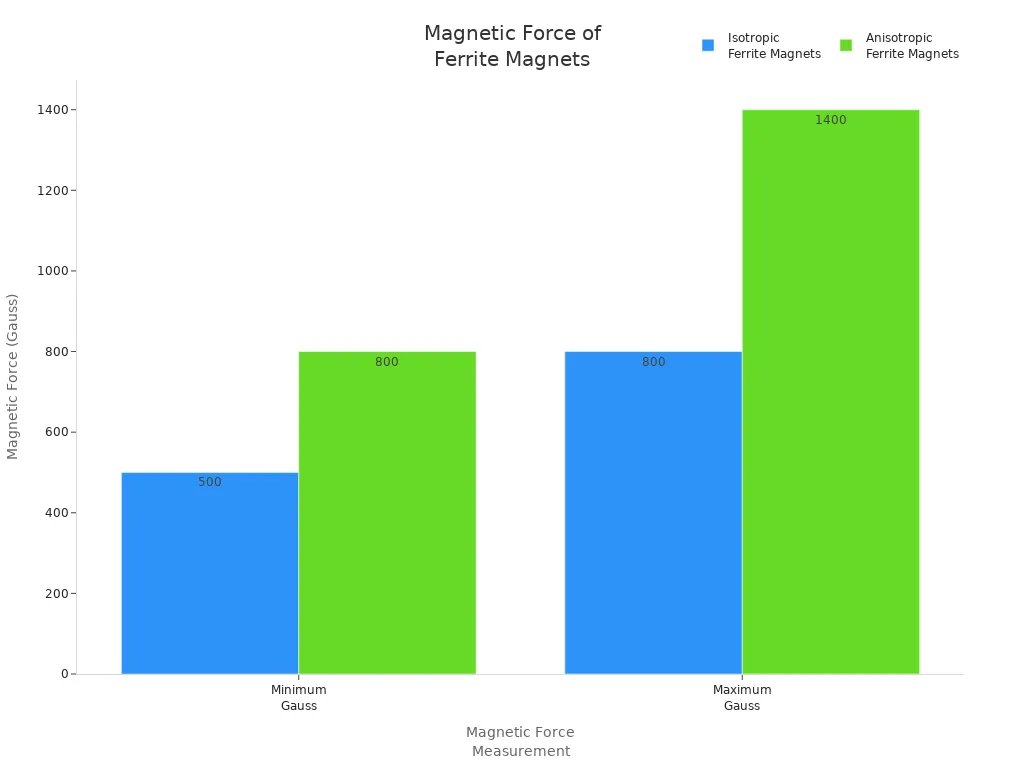

Ferrite magnets come in two main types: isotropic and anisotropic. The difference lies in how the magnetic domains align during manufacturing. Isotropic ferrite magnets have randomly arranged domains, so they can be magnetized in any direction. These magnets are easier and cheaper to produce but have lower magnetic strength. Anisotropic ferrite magnets, on the other hand, have domains aligned in a specific direction during the pressing process. This alignment gives them much higher magnetic strength, but they must be magnetized along the preferred axis.

The table below highlights the key differences:

Characteristic | Isotropic Ferrite Magnets | Anisotropic Ferrite Magnets |

|---|---|---|

Magnetic Domain Alignment | Randomly arranged during molding | Magnetically aligned in a preferred direction |

Magnetization Direction | Can be magnetized in any direction | Requires magnetization in a specific direction |

Magnetic Force (Gauss) | Approximately 800 – 1,400 gauss | |

Typical Applications | Simpler uses: refrigerator magnets, toys | High-performance uses: electric motors, sensors |

Manufacturing Cost | Lower cost, easier production | Higher cost, specialized manufacturing required |

Magnetic Strength | Weaker magnetic fields | Stronger magnetic fields |

Performance Under Stress | Moderate | Maintains higher efficiency under vibration |

Ferrite magnets made with isotropic powder work well for general purposes, such as refrigerator magnets and toys. Anisotropic ferrite magnets, made from specially aligned powder, serve in demanding applications like electric motors and sensors. The choice between isotropic and anisotropic types depends on the required magnetic strength and the intended use.

How Ferrite Magnets Work

Ferrimagnetism

Ferrimagnetism gives ferrite magnets their unique magnetic properties. In ferrite, atoms arrange themselves in a crystal structure called spinel. This structure contains two types of sites for metal ions: tetrahedral (A) and octahedral (B). The magnetic moments on these sites align in opposite directions, but their strengths are not equal. As a result, ferrite magnets show a net magnetic field.

The table below compares the interactions that create ferrimagnetism:

Interaction Type | Description | Strength and Role in Ferrimagnetism |

|---|---|---|

A–B interaction | Superexchange between ions on tetrahedral (A) and octahedral (B) sites via O2– ions, antiparallel alignment | Strongest interaction, dominant in spinel ferrites, causes opposite but unequal magnetic moments leading to net magnetization |

B–B interaction | Interaction between ions on octahedral (B) sites | Weaker than A–B, contributes less to net magnetization |

A–A interaction | Interaction between ions on tetrahedral (A) sites | Weakest, minimal effect due to larger distance and smaller bonding angle |

In ferrimagnetism, the magnetic moments point in opposite directions, but the imbalance between the two sublattices creates a net magnetization. This differs from ferromagnetism, where all moments align in the same direction, resulting in a stronger magnetic field. Ferrite magnets display this special type of magnetism, which makes them useful for many applications.

Ferrimagnetism in ferrite magnets leads to a net magnetic field, even though some atomic moments cancel each other out. This property sets ferrite apart from other types of magnets.

Magnetic Domains

Inside ferrite magnets, the material divides into tiny regions called magnetic domains. Each domain contains atoms with magnetic moments pointing in the same direction. In an unmagnetized ferrite, these domains point in random directions, so the overall magnet shows little or no magnetism.

When an external magnetic field is applied, domains that align with the field grow larger. Domains pointing in other directions shrink. The boundaries between these regions, called domain walls, shift as the domains change size. This process allows ferrite magnets to become magnetized and retain their magnetism even after the external field is removed.

The stability of these domains in ferrite comes from the material’s strong uniaxial anisotropy and the interactions between grains. These features help ferrite magnets keep their permanent magnetic properties. The size and shape of the domains depend on the composition and structure of the ferrite, as well as temperature and other factors.

Magnetic domains in ferrite magnets play a key role in how the magnet responds to external fields and how it holds its magnetism over time.

Magnetization Process

Manufacturers create ferrite magnets through a careful process. After forming and sintering the ferrite material, they apply a strong external magnetic field to the finished magnet. This field aligns the magnetic domains inside the ferrite, forcing them to point in the same direction. The magnet reaches a state called saturation, where almost all domains align with the field.

The strength of the applied field usually ranges from 955 to 1194 A/m (12 to 15 kOe). This value is about 2.5 to 3 times higher than the coercive force of the magnet. By using such a strong field, manufacturers ensure that the ferrite magnet achieves its maximum possible magnetization. After this step, the magnet retains its magnetic properties and is ready for use in various products.

The magnetization process locks in the magnetic domains, giving ferrite magnets their permanent magnetic strength.

Permanent Ferrite Magnets: Properties

Magnetic Strength

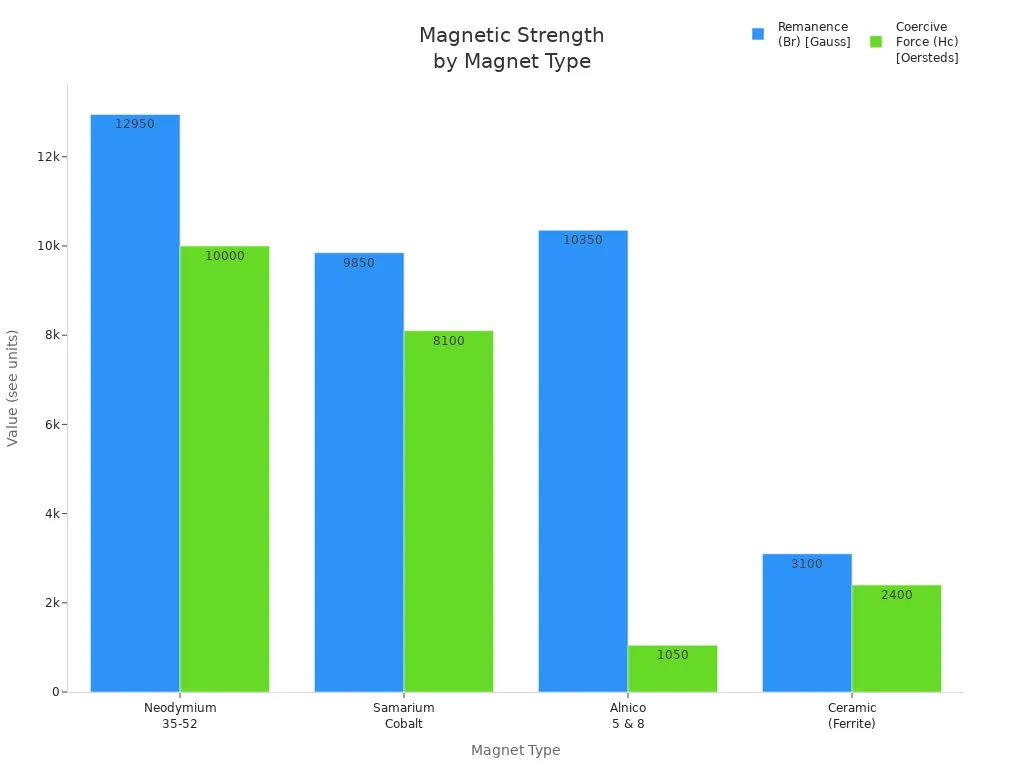

Permanent ferrite magnets offer reliable magnetic strength for many everyday uses. Their magnetic power comes from the alignment of magnetic domains within the ceramic structure. However, compared to rare earth magnets like neodymium or samarium-cobalt, permanent ferrite magnets have lower remanence and coercivity. Remanence measures how much magnetism remains after removing an external field, while coercivity shows how well a magnet resists becoming demagnetized.

The table below compares the magnetic strength of different magnet types:

Magnet Type | Max. Energy Product (BHmax) [MGOe] | Coercive Force (Hc) [Oersteds] | Typical Remanence (Br) [Gauss] |

|---|---|---|---|

Neodymium 35-52 | 33-53 | ≥10000 | 11800-14100 |

Samarium Cobalt | 16-30 | ≥8100 | 8700-11000 |

Alnico 5 & 8 | 4.0-5.5 | 600-1500 | 8200-12500 |

Ceramic (Ferrite) | 0.8-3.5 | 1600-3200 | 2300-3900 |

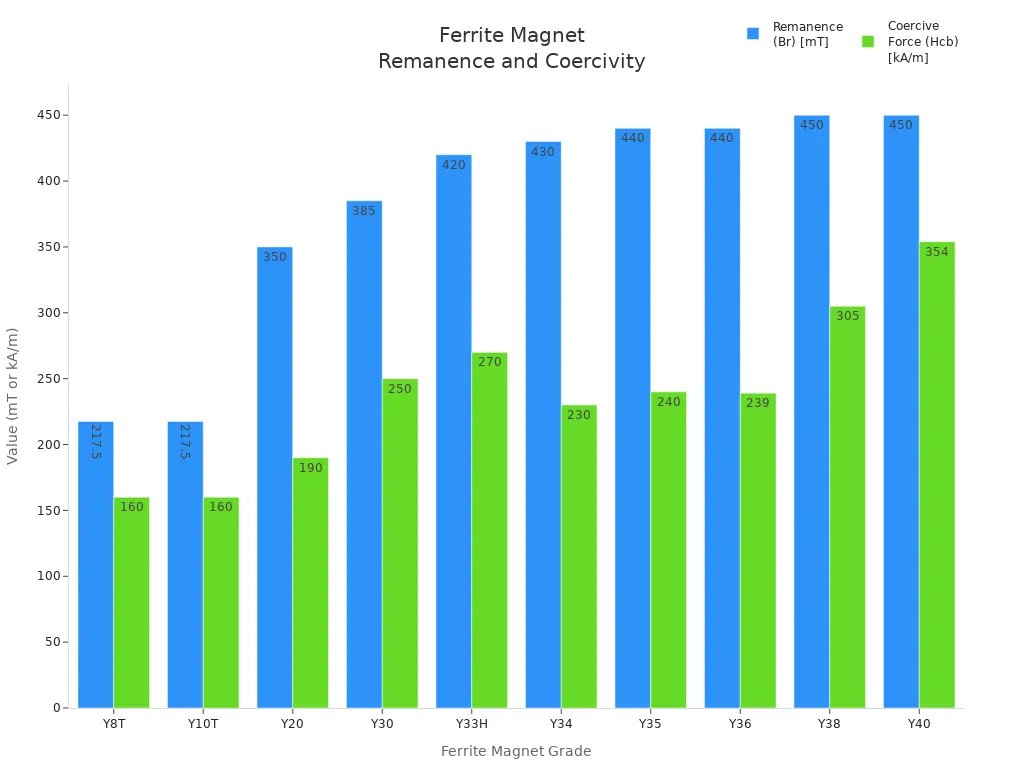

Permanent ferrite magnets typically show remanence values between 0.2 and 0.7 teslas. Their coercive force ranges from about 160 to 354 kA/m. These values make them weaker than neodymium magnets, which reach remanence values up to 1.4 teslas and much higher coercivity. The chart below visually compares the remanence and coercive force of common magnet types:

Despite their lower magnetic strength, permanent ferrite magnets remain popular because they are cost-effective and stable. Manufacturers produce a range of ferrite grades to suit different needs. The table below lists typical values for several grades:

Ferrite Magnet Grade | Remanence (Br) [mT] | Coercive Force (Hcb) [kA/m] | Intrinsic Coercive Force (Hcj) [kA/m] | Max. Energy Product (BHmax) [MGOe] |

|---|---|---|---|---|

Y8T | 200-235 | 160 | 280 | 0.8-1.2 |

Y20 | 320-380 | 190 | 195 | 2.3-2.7 |

Y30 | 370-400 | 250 | 255 | 4.0-4.4 |

Y35 | 430-450 | 240 | 240 | 4.2-4.8 |

Y40 | 440-460 | 354 | 360 | 4.7-5.3 |

Permanent ferrite magnets provide enough strength for motors, speakers, and household items. Their lower magnetic force also makes them safer for general use.

Tip: When selecting a permanent ferrite magnet, consider the grade and application to ensure the right balance of strength and safety.

Temperature Resistance

Permanent ferrite magnets perform well in a wide range of temperatures. They keep their magnetic properties even when exposed to heat or cold. Most permanent ferrite magnets can operate up to about 250°C before losing significant magnetism. Their Curie temperature, the point where they lose all magnetism, reaches around 450°C.

The table below compares the temperature resistance of common magnet types:

Magnet Type | Maximum Operating Temperature (°C) | Curie Temperature (°C) |

|---|---|---|

Alnico | ~525 | ~800 |

Ferrite | ~250 | ~450 |

Neodymium (NdFeB) | 80-200 (depending on grade) | 310-400 |

Permanent ferrite magnets resist higher temperatures than neodymium magnets, which often lose strength above 80°C. However, alnico magnets can withstand even higher temperatures, up to 525°C. This makes permanent ferrite magnets a good choice for devices that face heat, such as automotive parts and industrial motors.

Note: Permanent ferrite magnets offer a balance between magnetic strength and temperature resistance, making them suitable for many demanding environments.

Corrosion Resistance

Permanent ferrite magnets show excellent resistance to corrosion. Their ceramic structure does not rust or degrade when exposed to moisture, chemicals, or salt. This property makes them ideal for outdoor and marine applications, as well as in humid or wet environments.

The lifespan of permanent ferrite magnets depends on the application and environment. The table below shows typical lifespans in different industries:

Application Industry | Typical Lifespan Range | Key Factors Affecting Lifespan |

|---|---|---|

Automotive | 10 to 20 years | Exposure to varying temperatures and mechanical stress; proper design and installation critical |

Electronics and Consumer Devices | 15 to 30 years | Subject to high-frequency magnetic fields causing gradual demagnetization; operating conditions matter |

Medical Devices | Several decades | Exposure to strong magnetic fields; longevity depends on avoiding extreme temperatures and mechanical stress |

Permanent ferrite magnets maintain their quality over many years, even in harsh conditions. Their resistance to corrosion reduces the need for protective coatings, which lowers maintenance costs and increases reliability.

Permanent ferrite magnets provide long-lasting performance in challenging environments, making them a trusted choice for many industries.

Electrical Insulation

Permanent ferrite magnets stand out for their excellent electrical insulation. Their ceramic structure makes them electrically non-conductive, which brings several advantages in electronic applications:

High electrical resistivity prevents the flow of electric current through the magnet.

This property limits the formation of eddy currents, which often cause energy loss in metal-based magnetic cores.

Reduced eddy current losses mean less heat generation and improved efficiency, especially in alternating current (AC) and high-frequency devices.

Permanent ferrite magnets work well in high-frequency circuits, such as switch-mode power supplies, inverters, and radio frequency (RF) systems, because they channel magnetic flux efficiently while keeping core losses low.

Their insulating nature helps suppress electromagnetic interference (EMI), which protects signal integrity in sensitive electronic equipment.

Note: The electrical insulation of permanent ferrite magnets makes them a preferred choice for many modern electronic devices, where efficiency and signal clarity matter.

Brittleness

Ferrite magnets have a ceramic composition, which gives them both strength and brittleness. This characteristic affects how they perform in different environments and how users must handle them.

Mechanical Limitation | Effect on Ferrite Magnets |

|---|---|

Brittleness (ceramic nature) | Hard but brittle; prone to chipping or breaking under mechanical stress or impact |

Mechanical Strength | Limited due to brittleness; unsuitable for high mechanical loads, shocks, or vibrations |

Handling Requirements | Must be handled carefully to avoid dropping or stressing, as they can easily chip or break |

Application Impact | Not ideal for motors or vibrating environments where mechanical stress is common |

Permanent ferrite magnets can chip or break when exposed to mechanical stress. Their brittleness means they do not perform well in applications that involve frequent shocks, heavy loads, or constant vibration. Users must handle these magnets with care to prevent damage. This limitation restricts their use in certain environments, such as inside motors or machines that vibrate often. While their ceramic nature provides excellent corrosion resistance and cost savings, it also means that permanent ferrite magnets require careful handling and thoughtful application design.

Magnets: Comparison

Ferrite Magnets vs. Rare Earth

Ferrite magnets and rare earth magnets serve different needs in technology and industry. Ferrite magnets cost much less because they use abundant materials like iron oxide. Rare earth magnets, such as neodymium, use rare elements and require a more complex manufacturing process. This makes rare earth magnets much more expensive, especially in large-scale production. For example, ferrite magnets usually cost about $5–$10 per kilogram, while neodymium magnets can reach $30–$40 per kilogram.

The table below highlights the main differences:

Feature | Ferrite Magnets | Rare Earth Magnets |

|---|---|---|

Magnetic Strength | Lower; about 1/2 to 1/7 the strength of rare earth magnets | 2-7 times stronger; strongest permanent magnets available |

Cost | Economical and cost-effective | More expensive due to rare earth elements |

Corrosion Resistance | Resistant; no coating needed | Can corrode; often coated |

Durability | Brittle, can break easily | Also brittle, but harder to demagnetize |

Temperature Tolerance | Can lose coercivity above 248°C (480°F) | Lower Curie temperature; can lose magnetism above 248°C (480°F) |

Common Uses | Everyday applications, motors, speakers | High-strength needs, compact motors, sensors |

Ferrite magnets work well in budget-sensitive and high-volume applications. Rare earth magnets provide much higher magnetic strength, which is important for compact and powerful devices.

Note: Ferrite magnets offer 2-3 times more magnetic field per dollar in large-scale, cost-sensitive projects.

Ferrite Magnets vs. Alnico

Ferrite and alnico magnets both appear in many industries, but they have different strengths and weaknesses. Ferrite magnets resist corrosion and demagnetization better than alnico magnets. Alnico magnets, made from aluminum, nickel, and cobalt, can withstand much higher temperatures—up to 500°C. They also have higher magnetic strength, but they lose magnetism more easily if exposed to opposing magnetic fields.

The following table compares key properties:

Property | Ferrite Magnets | Alnico Magnets |

|---|---|---|

Composition | Iron oxide with strontium or barium | Aluminum, nickel, cobalt, iron |

Temperature Stability | Moderate | Very high (up to 500°C) |

Durability | Brittle, can chip easily | Mechanically stronger, less likely to crack |

Corrosion Resistance | High | Relatively high |

Magnetic Strength | Lower | High |

Demagnetization | High resistance | Easily demagnetized by opposing fields |

Cost | Cost-effective | More expensive |

Alnico magnets suit high-temperature environments, such as electric guitar pickups and sensors. Ferrite magnets remain the better choice for low-cost, corrosion-resistant needs.

Ferrite Magnets vs. Flexible Magnets

Flexible magnets use ferrite powder mixed with rubber or plastic. This blend creates a magnet that bends and shapes easily. Flexible magnets have much lower magnetic strength than solid ferrite magnets. They work best for lightweight uses, such as refrigerator magnets, labels, and crafts.

Key differences include:

Magnetic Strength: Ferrite magnets provide stronger magnetic fields than flexible magnets.

Durability: Flexible magnets resist breaking or chipping, while ferrite magnets can break if dropped.

Cost: Both types remain affordable, but flexible magnets cost slightly more due to added materials.

Applications: Ferrite magnets fit motors, speakers, and industrial uses. Flexible magnets fit signage, displays, and crafts.

Tip: Choose ferrite magnets for strength and stability. Use flexible magnets when shape and flexibility matter more than power.

Ferrite Magnets Applications

Electronics

Ferrite magnets play a vital role in modern electronics. Many electronic devices rely on these magnets for their stable performance and cost-effectiveness. Manufacturers often choose ferrite magnets for electric motors, loudspeakers, transformers, inductors, magnetic sensors, and magnetic recording devices. These applications benefit from the magnets’ high coercivity, which means they resist demagnetization even after long-term use. Ferrite magnets also offer good temperature stability and corrosion resistance, making them suitable for devices that operate in different environments.

Some of the most common electronic applications include:

Electric motors in appliances, vehicles, and industrial machinery

Loudspeakers and microphones for clear sound production

Transformers and inductors in power supplies and radio frequency circuits

Magnetic sensors for detecting position or movement

Magnetic recording devices such as tape recorders and credit card strips

Ferrite magnets provide reliable magnetic properties and durability, which are essential for mass-produced electronics. Their electrical resistivity reduces energy losses, especially in high-frequency circuits. These features make ferrite magnets indispensable in the electronics industry.

Household Uses

Many household products use ferrite magnets because of their affordability and long-lasting performance. Refrigerator door seals, small motors in blenders and fans, and loudspeakers all depend on these magnets. Ferrite magnets resist corrosion, so they last for years even in humid kitchens or bathrooms. Their ability to operate across a wide temperature range ensures that household appliances work reliably in different seasons.

Ferrite magnets also appear in toys, cabinet closures, and magnetic organizers. Their high coercivity keeps them magnetized over time, which is important for products that need a permanent magnetic force. The ceramic composition of ferrite magnets makes them safe and stable for everyday use. Homeowners benefit from these magnets because they combine low cost with dependable performance.

Tip: Ferrite magnets in household appliances help reduce maintenance needs and extend product lifespans.

Automotive

The automotive industry relies on ferrite magnets for many critical applications. These magnets appear in wiper motors, fuel pumps, and starter motors. Their heat resistance and reliability make them ideal for vehicles that face changing weather and road conditions. Ferrite magnets provide stable magnetic fields in electric motors, which are essential for smooth vehicle operation.

Automotive manufacturers choose ferrite magnets because they are cost-effective and durable. The magnets’ resistance to corrosion ensures that they last for many years, even in harsh environments. Ferrite magnets also come in various shapes and sizes, allowing engineers to design components that fit specific needs. Although ferrite magnets have lower magnetic strength than rare-earth types, their affordability and stability make them a popular choice for mass production.

Automotive applications benefit from the magnets’ high coercivity and high Curie temperature. These properties allow ferrite magnets to maintain performance even under the high temperatures found in engine compartments. As a result, ferrite magnets support the reliability and efficiency of modern vehicles.

Industrial

Ferrite magnets play a crucial role in many industrial applications. Factories and manufacturing plants rely on these magnets for their stability, durability, and cost-effectiveness. Their ability to maintain stable magnetism ensures that industrial equipment operates reliably, even under extreme conditions.

Many types of industrial machinery depend on ferrite magnets. Some of the most common applications include:

Electric motors and generators: Ferrite magnets convert electrical energy into mechanical energy and vice versa. This process is essential for automation and manufacturing.

Pumps and compressors: Motors in pumps and compressors often use ferrite magnets. Industries such as water treatment, food processing, and chemical manufacturing benefit from their reliability.

Conveyor systems: Motorized conveyor belts in factories, warehouses, and mining facilities rely on ferrite magnets for smooth and efficient movement.

Magnetic separation equipment: These magnets help separate metals from other materials, improving recycling and waste management processes.

Sensors and robotics: Ferrite magnets enable precise movement and positioning in automated machinery. Their anisotropic properties allow for accurate control in robotics and assembly lines.

Loudspeakers and audio equipment: Industrial environments often require robust audio systems. Ferrite magnets provide consistent sound quality in these settings.

The table below highlights the main advantages of ferrite magnets in industrial use:

Advantage | Description |

|---|---|

Durability | High resistance to physical and chemical wear ensures long-term functionality |

Corrosion Resistance | Performs well in harsh environments with moisture, chemicals, or high temperatures |

Cost-Effectiveness | Affordable compared to rare earth magnets, suitable for large-scale production |

Stable Magnetism | Maintains reliable operation, reducing downtime and maintenance costs |

Versatility | Supports a wide range of industrial applications |

Tip: Ferrite magnets help electric motors handle high workloads without overheating. This feature extends the lifespan of industrial equipment and reduces the need for frequent repairs.

Industrial engineers often choose ferrite magnets because they perform reliably in extreme temperatures and humid or corrosive environments. Their combination of power, affordability, and resistance to wear makes them indispensable in many industrial settings. As industries continue to automate and modernize, the use of ferrite magnets in new applications will likely increase.

Ferrite Magnets Handling and Selection

Choosing Ferrite Magnets

Selecting the right ferrite magnet for a project requires careful consideration of several factors. Each application has unique needs, so matching the magnet’s properties to the intended use ensures the best performance. Ferrite magnets come in many shapes and sizes, such as discs, blocks, rings, and cylinders. The choice depends on the space available and the required magnetic force.

The table below summarizes the main factors to consider when choosing ferrite magnets:

Factor | Description |

|---|---|

Strength | Ferrite magnets provide less pull force than neodymium magnets. Strength is measured by pull force or Gauss. |

Size and Shape | The magnet must fit the project. Common shapes include discs, blocks, rings, and cylinders. |

Temperature Resistance | Ferrite magnets operate up to 250°C without losing magnetism. |

Corrosion Resistance | These magnets resist moisture, chemicals, and rust. They work well in humid or underwater environments. |

Cost | Ferrite magnets are cost-effective and often the least expensive option. |

Environmental Conditions | Consider exposure to humidity, salt water, or chemicals. Ferrite magnets perform well in these settings. |

Application Matching | Match the magnet’s properties to its use, such as electronics, crafts, industrial, or medical devices. |

Ferrite magnets suit projects that need high temperature resistance, corrosion protection, and low cost. They work well in electronics, loudspeakers, motors, and medical devices. Their ceramic material makes them hard but brittle, so they should not be used where strong impacts or heavy loads occur. Ferrite magnets also have about one-seventh the pulling force of similar-sized neodymium magnets, so users should check if the strength meets their needs.

Tip: Always match the magnet’s size, shape, and strength to the specific requirements of the application for the best results.

Storage and Safety

Proper storage and safe handling of ferrite magnets help prevent damage and injury. Ferrite magnets can break or chip if dropped or struck, so careful handling is important. The following guidelines help ensure safe use and long-lasting performance:

Keep ferrite magnets away from electronic devices and items sensitive to magnetic fields.

Maintain a safe distance from pacemakers and implanted defibrillators.

Wear heavy protective gloves when handling large magnets to avoid pinched fingers or skin injuries.

Avoid drilling, sawing, or other mechanical treatments because ferrite magnets are brittle.

Store ferrite magnets at least 5 cm away from neodymium magnets to prevent demagnetization.

Package magnets with padding and arrange them to neutralize magnetic fields during shipping. Use magnetic shielding if needed.

Follow stricter packaging rules for airfreight to prevent interference with airplane navigation.

Do not expose ferrite magnets to temperatures below -40°C or above 250°C to avoid permanent loss of magnetic force.

Keep magnets out of reach of children to prevent swallowing hazards.

Place magnets securely to prevent them from falling or causing injury.

Warn individuals with pacemakers to keep a safe distance from magnets.

Note: Safe storage and handling protect both the magnets and the people using them. Proper care extends the life of ferrite magnets and reduces the risk of accidents.

Ferrite Magnets Trends

Technology Advances

Ferrite magnet technology has seen rapid progress in recent years. Manufacturers now use advanced materials and miniaturized components to create magnets that perform better and last longer. These improvements help electric vehicles run more efficiently. Motors built with new ferrite magnets show higher temperature stability, which increases vehicle range and reduces carbon emissions. Wind turbines also benefit from stronger and more durable magnets, making renewable energy more reliable.

Artificial intelligence (AI) has become a key part of ferrite magnet production. AI systems optimize manufacturing conditions, which leads to less material waste and higher precision. Automation powered by AI allows companies to scale up production and manage supply chains more effectively. Engineers use AI-driven simulations to design magnets with specific properties for robotics, healthcare, and consumer electronics. This approach speeds up development and ensures magnets meet the needs of modern devices.

New manufacturing methods, such as doping techniques and co-sintering, have improved the magnetic properties of ferrite magnets. Some companies now produce cobalt-free ferrite magnets, which lowers costs and reduces reliance on rare earth elements. These innovations allow for the creation of smaller, more versatile magnets. As a result, ferrite magnets now appear in a wider range of products, from medical imaging equipment to compact electronic devices.

AI and new materials have transformed ferrite magnet production, making magnets stronger, more efficient, and better suited for today’s technology.

Environmental Impact

Ferrite magnets offer significant environmental advantages over rare earth magnets. Their production process creates much less pollution and uses fewer hazardous materials. The table below compares the environmental and social impacts of ferrite magnets with those of rare earth magnets:

Aspect | Ferrite Magnets | Rare Earth (Nd–Fe–B) Magnets |

|---|---|---|

Production Environmental Burden | Significantly lower across most categories | Much higher due to mining and refining |

Main Impact Source | Electricity use during manufacturing | Mining and chemical processing of rare earths |

Climate Change Impact Reduction | High emissions, rare earths contribute ~50% | |

Eutrophication Marine Impact | Much lower | Up to 98% of impact from rare earth processing |

Human Health & Social Impacts | Lower accident rates, less hazardous waste | Higher accident rates, more hazardous waste |

Recycling Potential | Easier recycling and substitution | Recycling is complex and challenging |

Energy Consumption Sensitivity | Renewable energy can reduce footprint by ~90% | High energy and chemical demands remain |

Ferrite magnets do not require rare earth mining, which often harms the environment and poses risks to workers. Their main environmental impact comes from electricity use during manufacturing. Switching to renewable energy can reduce this footprint by up to 90%. Ferrite magnets also generate less hazardous waste and have lower accident rates in production. Recycling ferrite magnets is simpler, which further reduces their environmental impact.

Ferrite magnets provide a more sustainable choice for manufacturers and consumers who want to lower their environmental footprint.

Ferrite magnets combine ceramic strength, high electrical resistance, and excellent corrosion resistance, making them ideal for electronics, motors, and sensors. The table below highlights their unique properties:

Property | Description |

|---|---|

Temperature Stability | Operates up to 300°C, stable magnetic output |

Corrosion Resistance | Does not rust, withstands water and saltwater |

Electrical Insulation | High resistance, suitable for high-frequency use |

Brittleness | Hard but fragile, avoid mechanical stress |

Engineers value ferrite magnets for their cost-effectiveness and reliability. As electric vehicles, renewable energy, and digital devices advance, ferrite magnets will play an even greater role in modern technology.

Do you want to customize your own ferrite magnets

FAQ

What makes ferrite magnets different from neodymium magnets?

Ferrite magnets use ceramic materials and iron oxide. Neodymium magnets use rare earth metals. Ferrite magnets cost less and resist corrosion better. Neodymium magnets provide much stronger magnetic force but need protective coatings.

Can ferrite magnets lose their magnetism over time?

Ferrite magnets keep their magnetism for many years. Strong impacts or very high temperatures above 250°C can weaken them. In normal use, they rarely lose strength.

Are ferrite magnets safe to use around electronics?

Yes, ferrite magnets do not conduct electricity. They resist corrosion and do not damage most electronic devices. However, strong magnets can affect magnetic storage or sensitive sensors.

Why do ferrite magnets break easily?

Ferrite magnets have a ceramic structure. This makes them hard but brittle. Dropping or striking them can cause chips or cracks. Handle them with care to prevent damage.

What are common uses for ferrite magnets?

Manufacturers use ferrite magnets in motors, speakers, sensors, and household appliances. They also appear in toys, magnetic closures, and industrial equipment.

How should ferrite magnets be stored?

Store ferrite magnets in a dry place. Keep them away from strong magnetic fields and electronic devices. Use padding to prevent chips or cracks. Keep out of reach of children.

Do ferrite magnets work underwater?

Yes, ferrite magnets resist rust and corrosion. They work well in wet or underwater environments. Their ceramic material does not degrade in water.

Can ferrite magnets be recycled?

Yes, ferrite magnets can be recycled. Recycling helps reduce waste and saves resources. Many recycling centers accept ferrite magnets from old electronics or appliances.