| Table 1:General appearance inspection standards for block blanks |

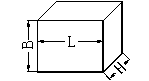

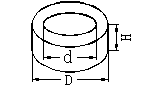

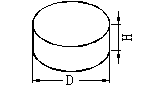

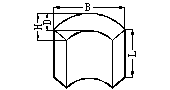

| Schematic diagram of the block blank | Size range (unit: mm) |

| L: perpendicular to the pressing direction

B: pressing direction

H: magnetization direction |

| 30≤L≤40

17≤B≤20

17≤H≤20 | 40≤L≤60

20≤B≤40

20≤H≤30 | 60≤L≤90

40≤B≤60

30≤H≤50 | 90≤L≤150

60≤B≤80

50≤H≤70 |

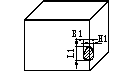

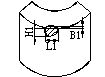

| Defect Category | Schematic diagram | Defect limit conditions |

| Plane gap |  | L1≤1.2

B1≤1

H1≤1 | L1≤1.5 B1≤1.2

H1≤1 | L1≤1.7

B1≤1.5

H1≤1.2 | L1≤2

B1≤1.6

H1≤1.5 |

| Impurities |  | D1≤0.3 | D1≤0.5 | D1≤1 | D1≤1.5 |

| Internal crack |  | Internal cracks are judged as unqualified |

| Table 2: General appearance inspection standards for ring blanks |

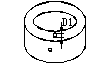

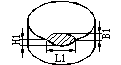

| Schematic diagram of the shape of the ring blank | Size range (unit: mm) |

| D: outer diameter of the ring

d: inner diameter of the ring

H: thickness (usually in the direction of magnetization) |

| 60≤D≤80

20≤d≤40

20 ≤H ≤40 | 80≤D≤100

40≤d≤60

20≤H≤40 | 100≤D≤120

60≤d≤80

20≤H≤40 | 120≤D≤140

80≤d≤100

20≤H≤40 |

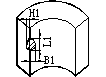

| Outer arc missing corner | Schematic diagram | Defect limit conditions |

| Outer arc missing corner |  | L1≤1.2

B1≤1

H1≤1 | L1≤1.5 B1≤1.2

H1≤1 | L1≤1.7

B1≤1.5

H1≤1 | L1≤2

B1≤1.6

H1≤1 |

| Impurities |  | D1≤0.5 | D1≤0.8 | D1≤1 | D1≤1.5 |

| Inner arc missing corner |  | L1≤1.2

B1≤1

H1≤1 | L1≤1.5

B1≤1.2

H1≤1 | L1≤1.7

B1≤1.5

H1≤1 | L1≤2

B1≤1.6

H1≤1 |

| Internal crack |  | Internal cracks are judged as unqualified |

| Table 3: General appearance inspection standards for cylindrical blanks |

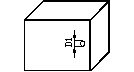

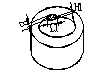

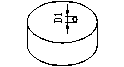

| Schematic diagram of a cylindrical blank shape | Size range (unit: mm) |

| D: outer diameter of cylinder

H: thickness (usually in the direction of magnetization) |

| 10≤D≤20

10 ≤H ≤20 | 20≤D≤40

20≤H≤40 | 40≤D≤60

20≤H≤40 | 60≤D≤80

20≤H≤40 |

| Defect Category | Schematic diagram | Defect limit conditions |

| Missing corner |  | L1≤1

B1≤1

H1≤0.8 | L1≤1.2 B1≤1.2

H1≤1 | L1≤1.5

B1≤1.2

H1≤1 | L1≤1.8

B1≤1.5

H1≤1 |

| Impurities |  | D1≤0.3 | D1≤0.5 | D1≤0.8 | D1≤1.2 |

| Internal crack |  | Internal cracks are judged as unqualified |

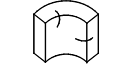

| Table 4: General appearance inspection standards for tile blanks |

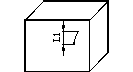

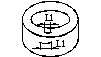

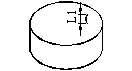

| Schematic diagram of the appearance of the tile blank | Size range (unit: mm) |

| L: length

B: width

D: thickness

H: arch height (D and H are generally the magnetization direction) |

| 20≤L≤40

20≤B≤40

20≤H≤40 | 40≤L≤60

20≤B≤40

20≤H≤40 | 60≤L≤80

30≤B≤50

30≤H≤50 | 60≤L≤80

40≤B≤60

30≤H≤50 |

| Defect Category | Schematic diagram | Defect limit conditions |

| Missing corner |   | L1≤1

B1≤1

H1≤1 | L1≤1.2

B1≤1

H1≤1 | L1≤1.5

B1≤1.2

H1≤1 | L1≤1.5

B1≤1.2

H1≤1.2 |

| Impurities |  | D1≤0.3 | D1≤0.5 | D1≤0.8 | D1≤1.2 |

| Internal crack |  | Internal cracks are judged as unqualified |