Alnico Magnet Industrial Bright Silver Customized Rectangular Magnet丨CORT

Alnico Magnet Product Overview

Alnico Magnet rectangular alnico magnet is a high-performance permanent magnet component specially designed for industrial scenarios, precision-manufactured from aluminum, nickel, and cobalt alloy. The product features a bright silver metallic finish with a standard rectangular structural design, supporting full-dimensional customized production. Its unique thickness direction magnetization characteristic ensures stable and long-lasting magnetic field performance in industrial environments, making it an ideal choice for various automation equipment, precision instruments, and high-end manufacturing fields.

Alnico Magnet Core Product Features

Physical Characteristics

| Item | Specification Parameters | Image Reference |

|---|---|---|

| Shape | Standard rectangular with right-angle edge design | Figure 3, Figure 6 |

| Color | Bright silver metallic luster, uniform consistency | All images |

| Surface Treatment | Precision machined, natural metallic texture | Figure 1, Figure 2 surface texture |

| Structural Features | Solid one-piece construction, no splicing seams | Figure 4, Figure 5 side view angles |

Magnetic Performance Features

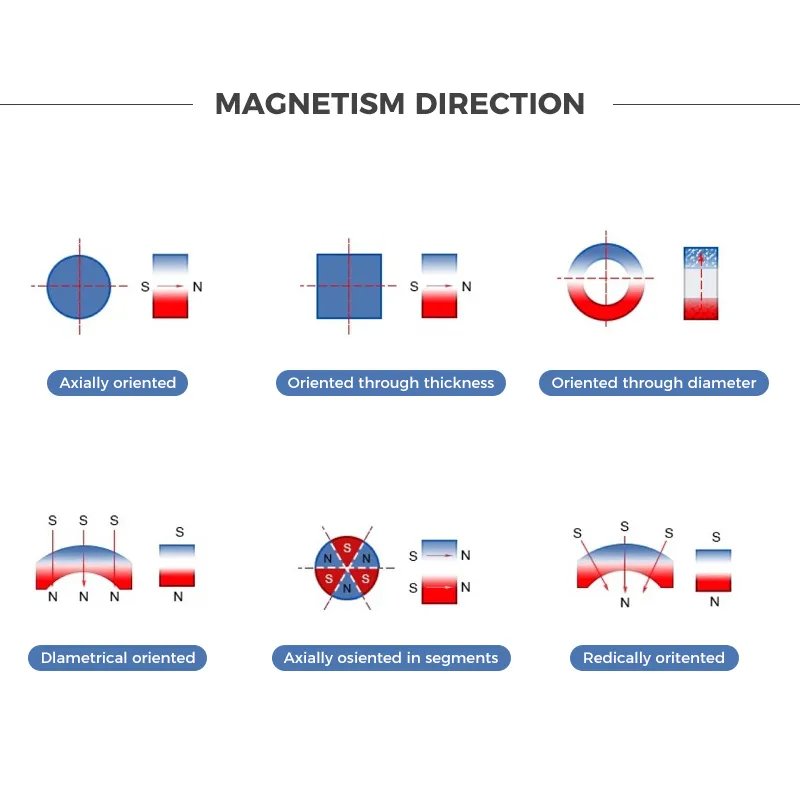

- Magnetization Direction: Thickness direction magnetized, magnetic field perpendicular to upper and lower surfaces

- Magnetic Stability: Wide temperature operating range from -40°C to +550°C, magnetic performance attenuation <3% in high-temperature environments

- Corrosion Resistance: The Original material has good corrosion resistance, supports custom surface coatings for enhanced protection

- Energy Product: 1.4-5.5 MGOe (can be custom adjusted according to application requirements)

According to industrial application requirements, providing comprehensive customization options:

Specification Customization

- Length: 10mm – 500mm (1mm step)

- Width: 5mm – 200mm (0.5mm step)

- Thickness: 2mm – 100mm (0.1mm step, determining magnetic field strength in magnetization direction)

- Tolerance Control: ±0.05mm (precision grade) / ±0.1mm (standard grade)

| Coating Type | Applicable Environment | Thickness | Color |

|---|---|---|---|

| Nickel plating | General industrial environments | 5-10μm | Silver-white |

| Zinc plating | Humid environment protection | 8-15μm | Silver-gray |

| Epoxy resin | Chemical corrosion environments | 20-50μm | Transparent/Black |

| Uncoated | Dry and clean environments | – | Natural bright silver |

- Size Customization: Besides the standard size, the length, width, and height can be adjusted according to actual customer needs to meet special installation space and magnetic action range requirements.

- Shape Customization: Can be customized into rings, circles, and irregular shapes to fit different magnetic field distribution needs and device structural design.

- Magnetic Customization: Based on the special requirement for magnetic field strength and direction in the application scenario, the magnetism of the magnet can be adjusted to ensure the best usage effect.

Alnico Magnet Industrial Application Scenarios

As a professional Industrial Magnet, widely used in:

- Automation Equipment: Servo motors, magnetic sensors, position encoders

- Manufacturing Industry: Metal sorting systems, mold positioning, welding fixtures

- Energy Equipment: High-temperature generators, special transformers, new energy equipment

- Testing Instruments: Non-destructive testing equipment, material testing platforms

- Transportation Systems: Magnetic conveyor lines, elevator door systems, rail transit braking devices

Alnico Magnet Product Advantages

- Extreme Environment Adaptation: 550°C high-temperature stability far exceeds neodymium magnets, suitable for high-temperature industrial scenarios such as metallurgy and casting

- Long-lasting Magnetic Performance: Annual magnetic decay rate <0.5%, 20-year service life design, reducing maintenance costs

- Precision Manufacturing Process: Dimensional tolerance controlled within ±0.05mm, meeting the precision installation requirements of automation equipment

- Full-process Customization: From material formulation to final dimensions, providing one-stop customization solutions

- Environmental Compliance: Meets RoHS standards,不含 heavy metal elements, suitable for high-end manufacturing environments

Alnico Magnet Technical Parameters Table

| Parameter Item | Specification Range | Testing Standard |

|---|---|---|

| Material Composition | Al-Ni-Co-Cu-Fe alloy | ASTM A801 |

| Remanence (Br) | 1.0-1.4T | IEC 60404-5 |

| Coercivity (Hc) | 350-500 Oe | IEC 60404-5 |

| Operating Temperature | -40°C ~ +550°C | ISO 9001:2015 |

| Density | 7.0-7.4 g/cm³ | ASTM B328 |

| Hardness (Hv) | 450-550 | ISO 6507-1 |

| Thermal Expansion Coefficient | 11×10⁻⁶/°C (20-200°C) | ASTM E228 |

Alnico Magnet Technical Parameters Table

- Installation Notes: Alnico material is hard and brittle; avoid severe impact. Recommend using non-magnetic fasteners (stainless steel screws)

- Magnetic Field Protection: Use low-carbon steel magnetic keepers during storage to prevent demagnetization; avoid placing against strong magnetic fields

- Cleaning and Maintenance: Wipe surface with dry cloth, use alcohol for oil stains, do not use acidic cleaners

- Demagnetization Treatment: If magnetic field strength adjustment is needed, professional equipment can perform partial demagnetization or complete demagnetization, followed by re-magnetization

- Safety Warning: Large-size products have significant weight, pay attention to anti-slip during handling; wear gloves to prevent fingerprint contamination on the bright silver surface

Frequently Asked Questions—alnico magnet

1. What is the size customization range for Alnico rectangular magnets, and what tolerances are available?

Full-dimensional customization is supported with the following ranges:

- Length: 10mm-500mm (1mm step increments)

- Width: 5mm-200mm (0.5mm step increments)

- Thickness: 2mm-100mm (0.1mm step increments)

Tolerance control reaches ±0.05mm (precision grade) or ±0.1mm (standard grade), meeting the precision installation requirements of automated equipment.

2.What is the temperature stability range, and in what environments is it suitable?

The product exhibits excellent temperature stability with an operating range of -40°C to +550°C. In high-temperature environments, magnetic performance attenuation is less than 3%, making it ideal for metallurgical, casting, and other high-temperature industrial scenarios where traditional magnets would fail.

3. What are the core advantages of Alnico magnets compared to neodymium (NdFeB) magnets?

The key advantages are threefold:

- Extreme temperature resistance: Stable operation at 550°C, compared to neodymium magnets typically limited to 150°C

- Magnetic permanence: Annual magnetic decay rate <0.5% with a 20-year design lifespan, reducing maintenance costs

- Material stability: Alnico alloy offers inherent corrosion resistance without relying on protective coatings (custom coating options available)

4.What precautions should be taken during installation and handling?

Important considerations include:

- Mechanical properties: Material is hard and brittle; avoid severe impact or dropping

- Mounting hardware: Use non-magnetic fasteners (e.g., stainless steel screws)

- Magnetic protection: Store with low-carbon steel magnetic keepers to prevent demagnetization

- Surface care: Wear gloves when handling large products to prevent fingerprint contamination on the bright silver finish

5.Is custom magnetization direction available, and what is the minimum order quantity?

- Magnetization options: Standard thickness-direction magnetization; radial, axial, or custom directions available (detailed magnetic field distribution requirements needed)

- Minimum order quantity: 100 units for standard products; sample orders negotiable (5-50 units)

- Lead time: 7-10 days for standard products; 15-20 days for customized products (including special magnetization directions)