Alnico Magnets 5 High-Temperature Permanent Magnet丨CORT

Alnico Magnets Product Specification Table

| Parameter | Details |

|---|---|

| Material Grade | Alnico 5 |

| Magnetic Properties | Br: 1.22-1.27 T Hcb: 48-56 KA/m HcJ: 49-57 KA/m (BH)max: 38-40 KJ/m³ |

| Operating Temperature Range | ≤550℃ (Excellent high-temperature stability) |

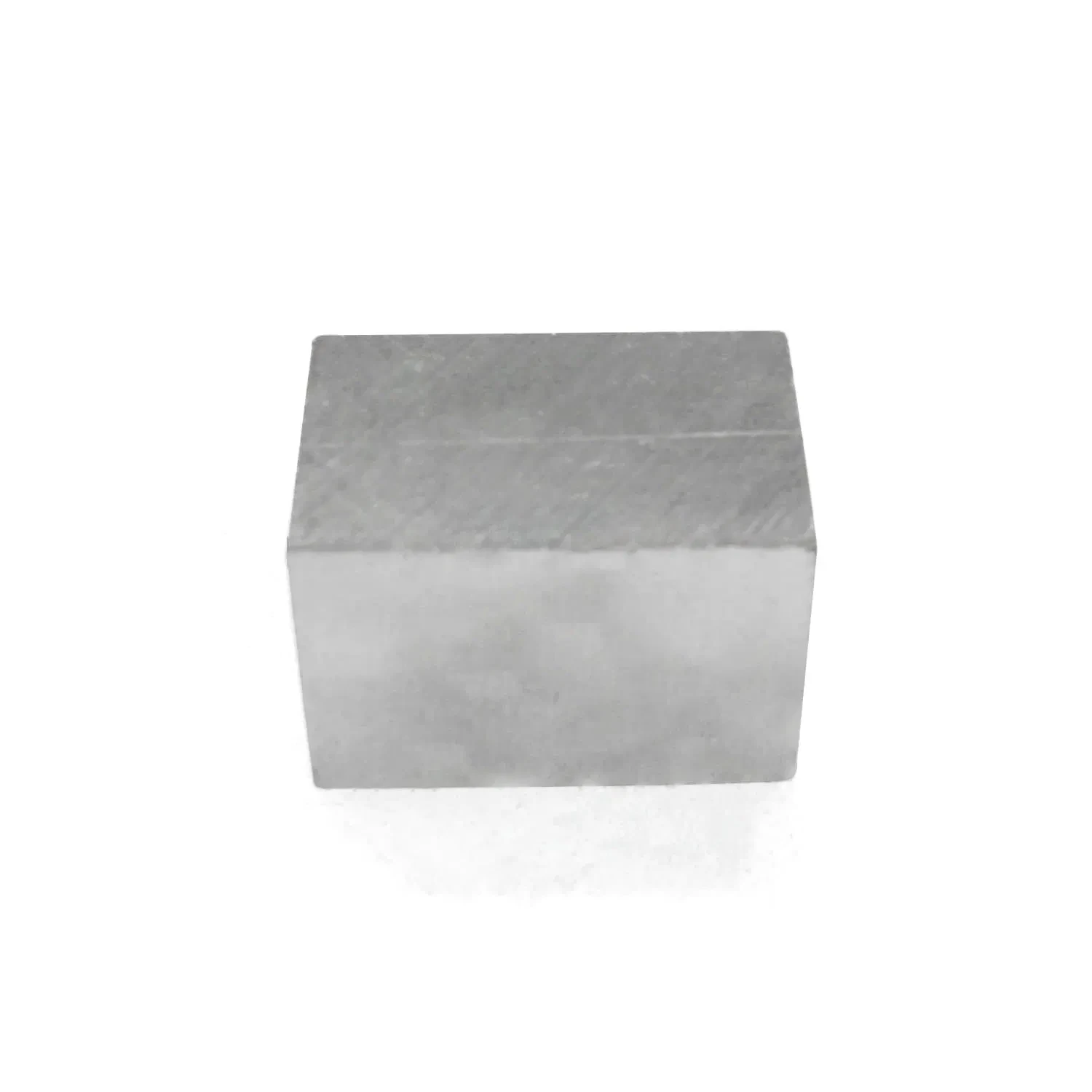

| Standard Dimensions | 66.5×13×3 mm (Length×Width×Height) |

| Customizable Size Range | Blocks: L:30-150mm, B:17-80mm, H:17-70mm Rings: D:60-140mm, d:20-100mm, H:20-40mm |

| Coating Options | Nickel Coating: – Barrel plating: 5~20μm thickness, salt spray test ≤48h – Rack plating: 5~20μm thickness, salt spray test ≤16h Operating temperature ≤200℃ |

| Applications | Speaker magnets, Industrial magnets, Jewelry magnets, Solenoids, Motor magnets |

Alnico Magnets Detailed Features

Excellent Magnetic Performance

- High Remanence: 1.22-1.27 T high remanence ensures strong magnetic flux output

- Superior Energy Product: Maximum energy product of 38-40 KJ/m³ provides efficient energy conversion

- Stable Coercivity: Maintains 48-56 KA/m coercivity even at high temperatures, ensuring long-term magnetic stability

Extreme Temperature Resistance

- Ultra-high Temperature Operation: Stable performance at temperatures up to 550℃, far exceeding neodymium and ferrite magnets

- Low Temperature Coefficient: Minimal magnetic property variation across a wide temperature range, ideal for high-temperature industrial environments

Precision Manufacturing

- Strict Dimensional Tolerance: Custom products maintain ±0.05mm tolerance for precise assembly

- Premium Surface Treatment: Nickel coating provides dual protection, enhancing corrosion and wear resistance

- Uniform Magnetization Direction: Multi-direction magnetization options are available to ensure optimal magnetic circuit design

Versatile Customization Capabilities

- Flexible Size Options: Full range customization from micro to large sizes to meet diverse application needs

- Special Shape Processing: Customizable blocks, rings, cylinders, and special shapes for complex installation spaces

- Performance Grade Adjustment: Magnetic parameters optimized according to customer requirements to balance cost and performance

Industrial Motors

- High-temperature Motors: Suitable for automotive engines and industrial furnace high-temperature motors

- Precision Servo Motors: Provides a stable magnetic field for high-precision motor control

- Traction Motors: High energy product enhances motor power density

Acoustic Equipment

- High-end Speakers: Delivers a clear, stable magnetic field for improved sound quality

- Microphones: High-sensitivity magnetic circuit design captures subtle sounds

- Sensors: Stable magnetic performance ensures detection accuracy

Industrial Automation

- Solenoid Valves: Fast response improves valve control precision

- Magnetic Fixtures: Secure workpiece holding in high-temperature environments

- Magnetic Separation Equipment: Efficient separation of ferrous contaminants

Alnico Magnets Product Advantage Summary

Alnico 5 permanent magnet is a high-performance, high-stability magnetic material specifically designed for high-temperature environments and applications requiring long-term reliability. Its exceptional temperature stability (≤550℃) and superior magnetic properties make it irreplaceable in motors, acoustic equipment, and industrial automation. Nickel coating provides excellent corrosion resistance, while flexible customization capabilities ensure adaptability to complex application requirements. Whether standard size or custom design, Alnico 5 permanent magnets deliver stable and reliable magnetic solutions for your products.

Alnico Magnet Technical Parameters Table

| Parameter Item | Specification Range | Testing Standard |

|---|---|---|

| Material Composition | Al-Ni-Co-Cu-Fe alloy | ASTM A801 |

| Remanence (Br) | 1.0-1.4T | IEC 60404-5 |

| Coercivity (Hc) | 350-500 Oe | IEC 60404-5 |

| Operating Temperature | -40°C ~ +550°C | ISO 9001:2015 |

| Density | 7.0-7.4 g/cm³ | ASTM B328 |

| Hardness (Hv) | 450-550 | ISO 6507-1 |

| Thermal Expansion Coefficient | 11×10⁻⁶/°C (20-200°C) | ASTM E228 |

Frequently Asked Questions—alnico magnets

1. What advantages does Alnico 5 magnet have compared to neodymium magnets?

The main advantages of Alnico 5 magnets are their extremely high operating temperature (≤550℃) and excellent magnetic stability, making them suitable for high-temperature applications. While neodymium magnets offer higher energy product, they typically operate below 150℃ and have larger temperature coefficients.

2.How to choose the appropriate coating process?

Barrel plating is suitable for mass-produced standard parts, providing more uniform coating thickness and longer salt spray test duration (≤48h). Rack plating is suitable for irregular and large products, offering better coverage on complex surfaces despite shorter salt spray test duration (≤16h).

3. What is the lead time for custom products?

Standard size products are typically delivered within 7-10 working days. Custom sizes and special performance requirements have a lead time of 15-20 working days, which can be negotiated based on order quantity.

4.What precautions should be taken for storage and handling of Alnico 5 magnets?

Store in a dry environment and avoid contact with corrosive substances. Although nickel coating provides protection, avoid severe impact and scratches. Magnetization direction should be kept away from other strong magnetic fields to prevent demagnetization.