Big Cast AlNiCo Magnet 5 Ring Permanent Magnet丨CORT

Big Cast AlNiCo Magnet Product Specification Table

| Project | Specification |

|---|---|

| Material Grade | AlNiCo 5 (Aluminum-Nickel-Cobalt Alloy) |

| Magnet Type | Permanent |

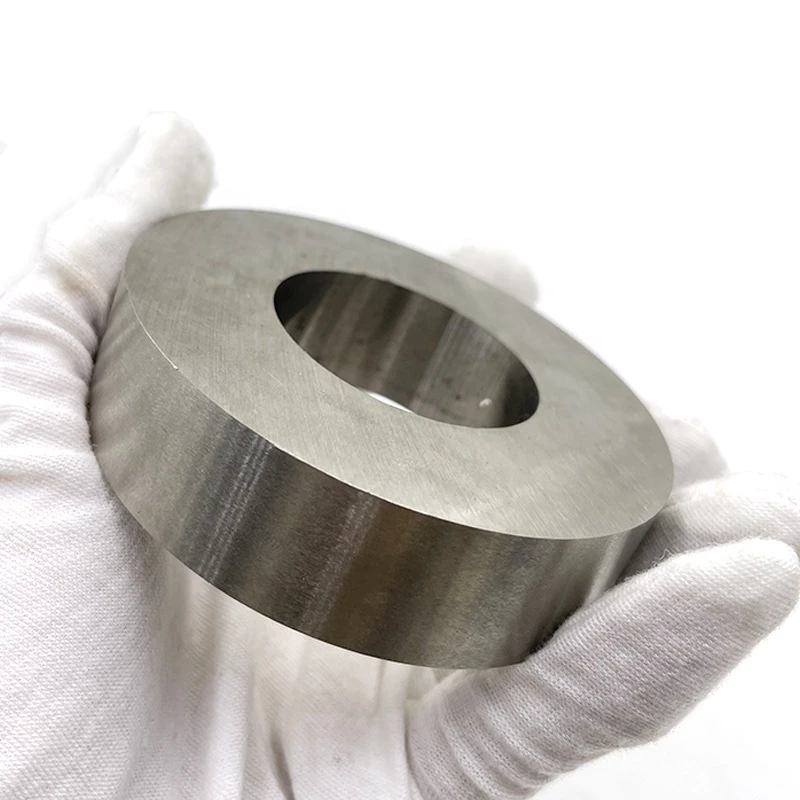

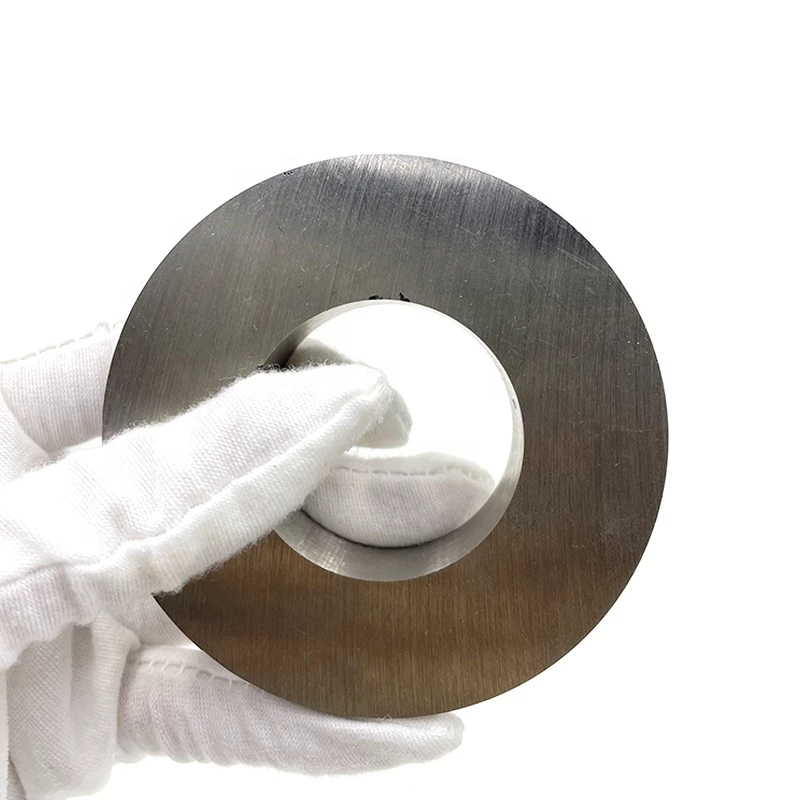

| Shape | Ring (Annular) |

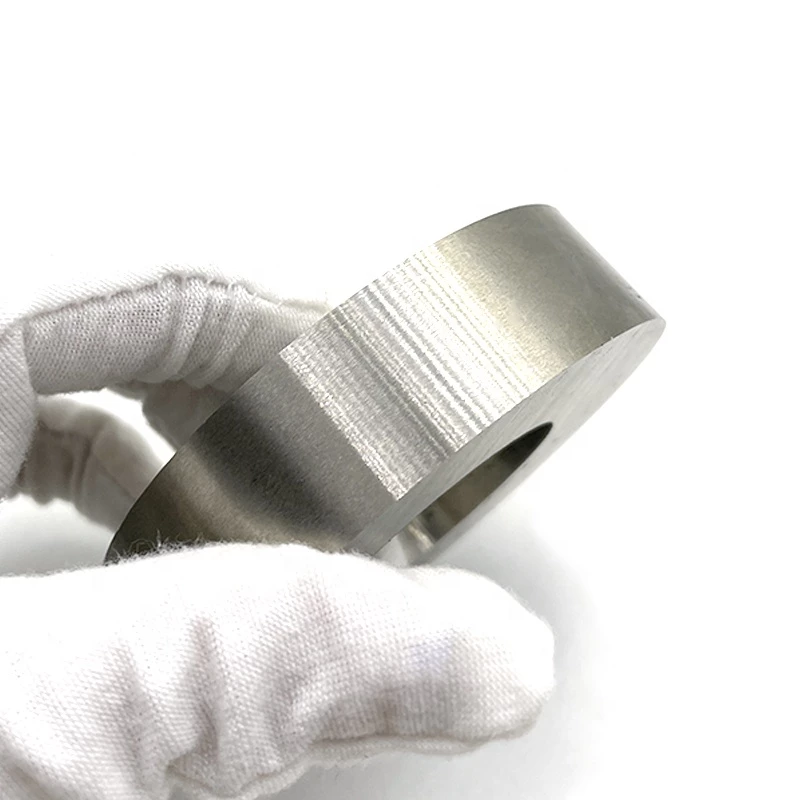

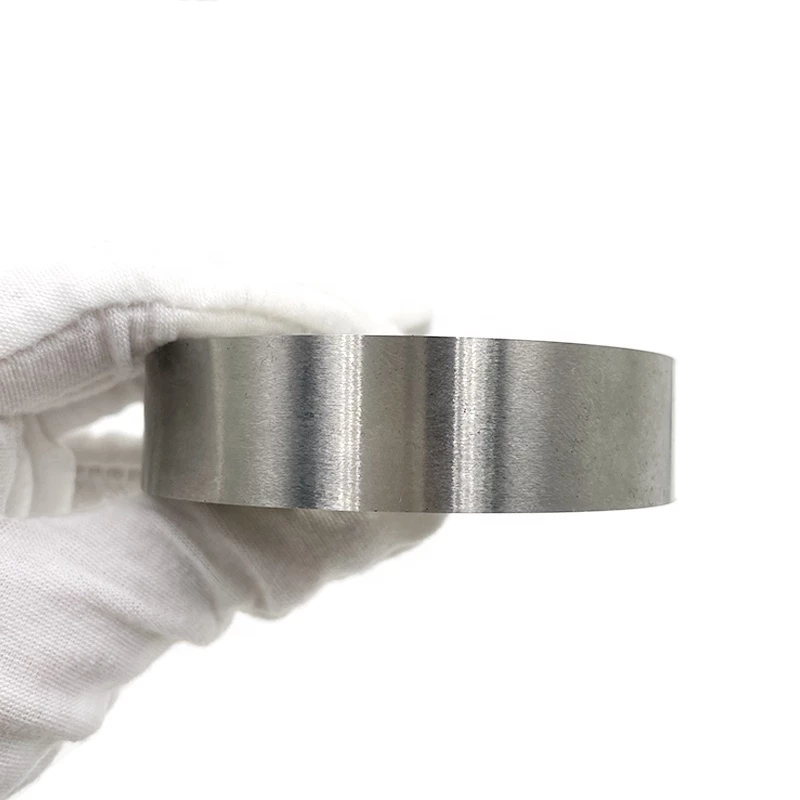

| Dimensions | 160×120×20mm (Outer Diameter×Inner Diameter×Thickness) |

| Magnetism Direction | Axial or Customizable |

| Processing Services | Bending, Welding, Decoiling, Cutting, Punching, Moulding |

| Sample Support | YES |

| Remanence (Br) | 1.2-1.3 T (12000-13000 Gauss) |

| Coercivity (HcB) | 48-56 kA/m (600-700 Oe) |

| Max Energy Product | 37-44 kJ/m³ (4.6-5.5 MGOe) |

| Operating Temperature | -250℃~550℃ |

| Curie Temperature | 860℃ |

| Tolerance | ±0.1mm (Customizable to ±0.05mm) |

| Surface Treatment | Nickel Plating (Optional: Zinc, Epoxy Coating) |

Big Cast AlNiCo Magnet Detailed Features

- Large-Size Casting Technology: Precision-cast annular structure with 160mm outer diameter, enabling large-scale magnetic field applications in industrial equipment.

- Versatile Processing Capabilities: Comprehensive manufacturing services including bending, welding, cutting, and punching to meet complex industrial requirements.

- Customizable Magnetization: Axial magnetization as standard with optional radial or multi-pole magnetization patterns available upon request.

- Industrial-Grade Durability: Maintains stable magnetic performance in extreme temperatures (-250℃~550℃), suitable for heavy machinery operating environments.

- Exceptional Mechanical Strength: Robust cast construction resists mechanical stress and vibration in industrial applications.

- Tailored Surface Treatments: Multiple coating options, including nickel, zinc, and epoxy, to enhance corrosion resistance for specific operating environments.

- Scalable Production: Capable of both prototype development and mass production with sample availability for qualification testing.

- Heavy Industrial Machinery: Used in large motors, generators, and drive systems requiring powerful and stable magnetic fields.

- Magnetic Separation Equipment: Ideal for large-scale mineral processing and material separation systems in mining and recycling industries.

- Aerospace & Defense: Suitable for guidance systems and large actuator components in military and aerospace applications.

- Power Generation: Applied in turbine generators and renewable energy systems requiring high-temperature stability.

- Marine Engineering: Used in underwater equipment and ship propulsion systems where corrosion resistance is critical.

- Infrastructure Projects: Suitable for magnetic levitation systems, large-scale sensors, and industrial automation equipment.

Big Cast AlNiCo Magnet Product Advantage Summary

Big Cast AlNiCo Magnet represents a premium solution for industrial applications requiring large-format permanent magnets. With its annular design (160×120×20mm), versatile processing options, and exceptional temperature stability, this AlNiCo 5 magnet delivers reliable performance in heavy machinery, power generation, and aerospace systems. The combination of customizable magnetization, comprehensive manufacturing services, and industrial-grade durability makes it an ideal choice for demanding engineering projects requiring both size and performance.

Big Cast AlNiCo Magnet Technical Parameters Table

| Parameter Item | Specification Range | Testing Standard |

|---|---|---|

| Material Composition | Al-Ni-Co-Cu-Fe alloy | ASTM A801 |

| Remanence (Br) | 1.0-1.4T | IEC 60404-5 |

| Coercivity (Hc) | 350-500 Oe | IEC 60404-5 |

| Operating Temperature | -40°C ~ +550°C | ISO 9001:2015 |

| Density | 7.0-7.4 g/cm³ | ASTM B328 |

| Hardness (Hv) | 450-550 | ISO 6507-1 |

| Thermal Expansion Coefficient | 11×10⁻⁶/°C (20-200°C) | ASTM E228 |

Frequently Asked Questions—Big Cast AlNiCo Magnet

1. What are the standard dimensions of the Big Cast AlNiCo Magnet?

The standard size is 160×120×20mm (Outer Diameter×Inner Diameter×Thickness). Custom sizes are available upon request with minimum order quantities.

2.What magnetic properties does the AlNiCo 5 material offer?

AlNiCo 5 provides remanence (Br) of 1.2-1.3 T, coercivity (HcB) of 48-56 kA/m, and maximum energy product of 37-44 kJ/m³, delivering strong and stable magnetic performance.

3. What is the operating temperature range of this Big Cast AlNiCo Magnet?

It maintains stable performance from -250℃ to 550℃, making it suitable for high-temperature industrial applications.

4.What processing services are available for customization?

We offer comprehensive processing including bending, welding, decoiling, cutting, punching, and moulding to meet specific application requirements.

5.Can the magnetization direction be customized?

Yes, standard magnetization is axial, but radial or multi-pole magnetization patterns can be customized based on your application needs.