Customizable Alnico Magnets-Personalized Magnetic Products丨CORT

AlNiCo Magnets Product Overview

Introducing CORT’s Customizable Alnico Magnets – Personalized Magnetic Products. Alnico magnets, an alloy of aluminum, nickel, and cobalt, are well known for their excellent magnetic properties and temperature stability. Our customizable alnico magnets are designed to meet various needs, whether it’s for industrial applications, electronic device manufacturing, or scientific research projects.

AlNiCo Magnets Core Materials and Characteristics

- Material: Made from AlNiCo Magnet, this alloy gives the magnet good corrosion resistance and high temperature stability, so it can maintain stable magnetic performance in different environments.

- Grade: The grade is ALNICO 5, one of the most popular grades. It offers a good balance of magnetic energy, coercivity, and temperature coefficient. It can deliver energy to a magnetic circuit efficiently, suitable for many applications.

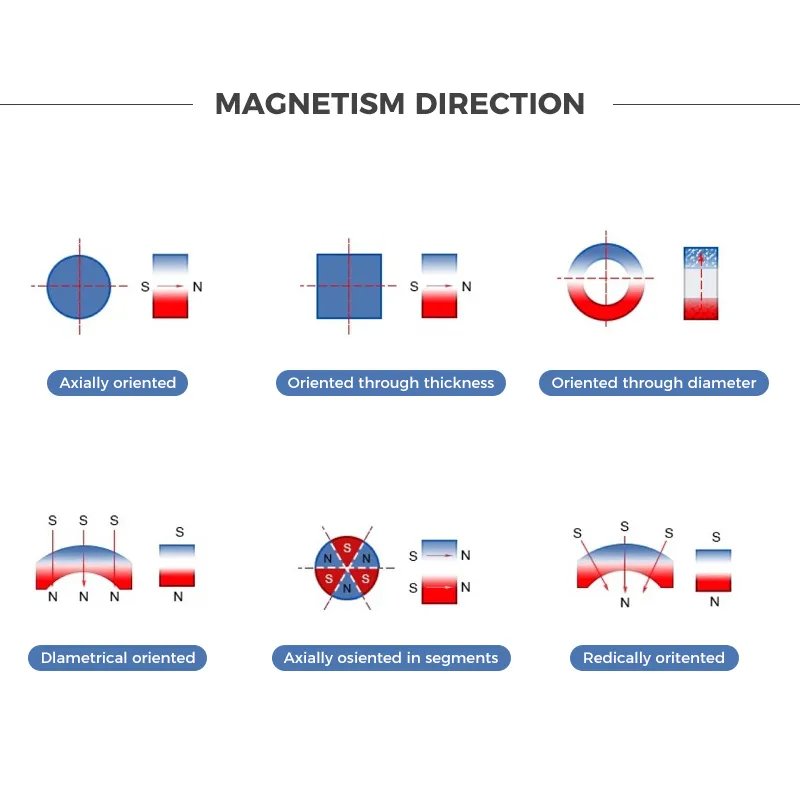

- Magnetism Direction: The magnetism direction is along the thickness. This directional magnetization is beneficial in applications where a specific magnetic field orientation is required, such as in some electrical motors or sensors.

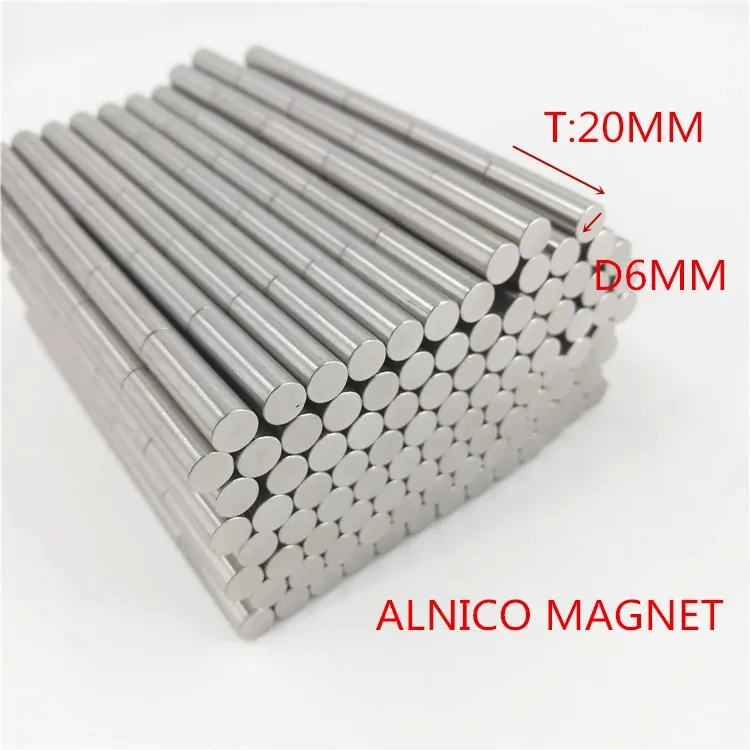

- Specification: Dia6*20mm, a standard size that can be applied to many common scenarios. But customization is also available to meet special dimensional requirements.

- Color: The bright silver color not only looks good but also reflects the good condition of the surface, which may be related to the coating or the material itself.

- Tolerance: Tolerance is set to +/-0.05mm, high precision manufacturing. This ensures accurate assembly and consistent performance when used in different devices.

AlNiCo Magnets Manufacturing and Types

- Casting vs Sintering: Hawell Magnetics offers both cast and sintered Alnico Magnets in various grades, including Alnico 2, Alnico 5, Alnico 5-7, and Alnico 8. Cast Alnico is the most common. Casting is often used to produce “near net shape” Alnico magnets, which can reduce machining cost and maintain good magnetic properties. Sintered Alnico magnets are less common due to their lower magnetic performance and limitations in forming complex shapes.

- Anisotropic and Isotropic: Anisotropic magnets have the direction of magnetisation (DoM) built into the structure, so they can achieve maximum performance in one direction. Isotropic magnets have a direction of an axis. Isotropic magnets have no direction of magnetisation, so they can be magnetised in multiple ways but have reduced performance.

AlNiCo Magnets Customization Options

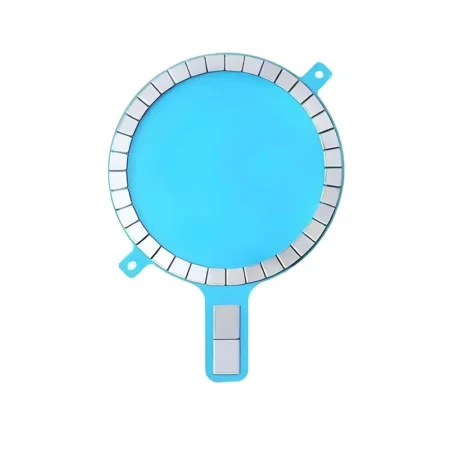

- Shape Customization: In addition to the standard Dia6*20mm, we can customize alnico magnets into various shapes such as rings, bars, horseshoes, etc., according to your application requirements.

- Grade and Performance Customization: We can adjust the grade or fine-tune the magnetic performance parameters according to your needs. For example, if you need higher coercivity or better temperature stability for your application, we can customize the magnet to meet those requirements.

- Special Requirements: Whether it’s for a specific coating, special surface treatment, or unique magnetization direction, we can work with you to develop personalized magnetic solutions.

AlNiCo Magnets Wholesale Benefits

- Large Supply: We have advanced production facilities and efficient production lines, so we can ensure a stable and sufficient supply for small batch and large batch orders.

- Cost Effective: Through optimized production processes, large-scale raw material procurement, and efficient management, we can offer competitive prices for bulk purchase, help you reduce cost while maintaining high-quality products.

- Quality Guarantee: A strict quality control system is in place, covering every stage from raw material inspection to final product testing. Each alnico magnet undergoes multiple quality checks to ensure consistent magnetic performance, accurate dimensions, and reliable quality.

AlNiCo Magnets Application

- Industrial Applications: Widely used in rotating machinery such as motors and generators, where their high temperature stability and good magnetic properties can ensure long-term and reliable operation. Also used in meters, instruments, and sensing devices for stable magnetic fields.

- Electronic Devices: In audio equipment like speakers and guitar pickups, Alnico 5 magnets can provide warm and rich sound quality. Also used in some precision electronic components where stable magnetic fields are required.

- Medical and Aerospace Fields: In medical devices, they can be used in some sensors or actuators. In aerospace equipment, their high temperature resistance and stable magnetic performance make them suitable for various components.

AlNiCo Magnets Installation and Maintenance

- Installation: During installation, please handle the magnets carefully to avoid damage. Since the magnetism direction is along the thickness, please ensure proper orientation according to application requirements. If you need any help with installation, our technical team can provide detailed guidance.

- Maintenance: Alnico magnets have good corrosion resistance, but please keep them away from strong corrosive substances. Check the surface regularly for any damage or wear. If stored for a long time, please store them in a dry and cool environment to maintain their magnetic performance.

AlNiCo Magnets Product Features Summary

- High-quality Material: Made from high-quality AlNiCo alloy, ALNICO 5 grade, with overall good performance.

- Customizable: Can meet various customized requirements, from shape to magnetic performance.

- Wide application: Suitable for many industries and applications, with good magnetic properties and temperature stability.

- Reliable quality: Strict quality control for both small and large batches.

Frequently Asked Questions—alnico magnets

1. What is the difference in performance between cast and sintered Alnico magnets?

Cast Alnico magnets are more common and have better magnetic performance. They can be made into “near net shape” and are suitable for complex shapes. Sintered Alnico magnets have lower magnetic performance and are often limited to simpler shapes.

2. Can I get samples before placing a bulk order?

Yes, we can send you samples to test and evaluate. Please contact our sales team to discuss the sample-related details, such as sample cost and delivery time.

3. How long does it take for customized products to be delivered?

The delivery time for customized products depends on the complexity of the customization. Generally, it will take 10-20 working days. We will confirm the exact delivery time with you based on your specific order requirements.

4. What kind of coating options do you offer for these alnico magnets?

We offer zinc, nickel, titanium, silver, gold, epoxy, and Parylene coating. The coating can be customized according to your application environment and requirements.

5. Are these alnico magnets suitable for high temperature environments?

Alnico magnets, especially ALNICO 5 grade, have good temperature stability and can be used in relatively high temperatures (e.g., many industrial applications where the temperature is not extremely high). But if you need to use them in extremely high temperature environments, please contact us for more advice and product recommendations.