Customizable NdFeB Magnet-Personalized Magnetic Solution丨CORT

NdFeB Magnet Product Overview

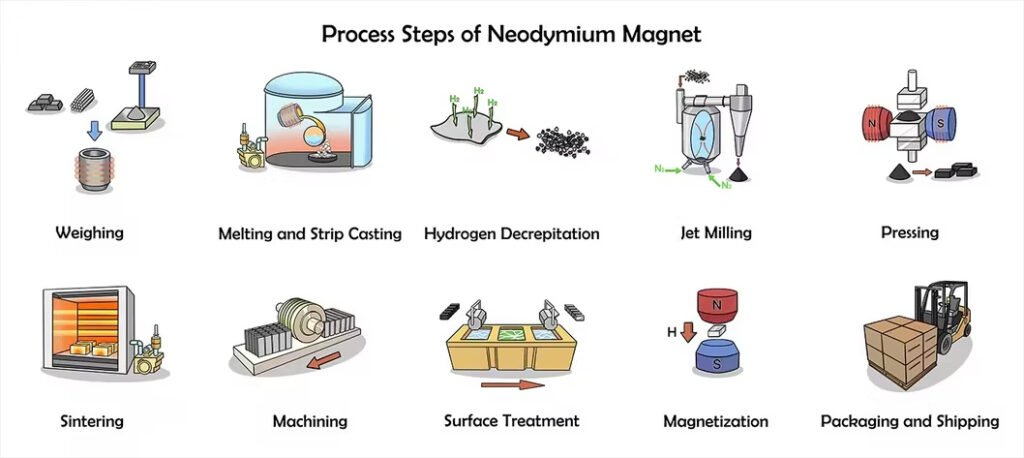

The Customizable NdFeB Magnet – Personalized Magnetic Solution from CORT is a unique magnetic product. As the third-generation rare earth permanent magnet material, NdFeB magnets have been widely used in many fields due to their excellent magnetic properties. This magnet is designed to meet various needs and can play a key role in many scenarios, whether it’s industrial production, electronic device manufacturing, or creative design projects, thanks to its great performance.If you need custom neodymium magnets, you can contact us and we will provide you with a professional one-stop customized solution

NdFeB Magnet Core Materials and Features

- Material Composition: Sintered neodymium, iron, boron, metal (neodymium iron boron magnets). This combination of materials gives the magnet strong magnetism, one of the strongest permanent magnets available.

- Neodymium magnet grades and Performance: N52, high remanence, high coercivity, high magnetic energy product. It can achieve strong magnetism in a small volume and meet the strict requirements of many high-end and precision applications.

- Coating: Standard Ni-Cu-Ni coating, customized coatings available. Ni-Cu-Ni coating can enhance the corrosion resistance of the magnet and extend its life. Customized coatings can be adjusted according to special usage environments and requirements, further improving the protection of the magnet.

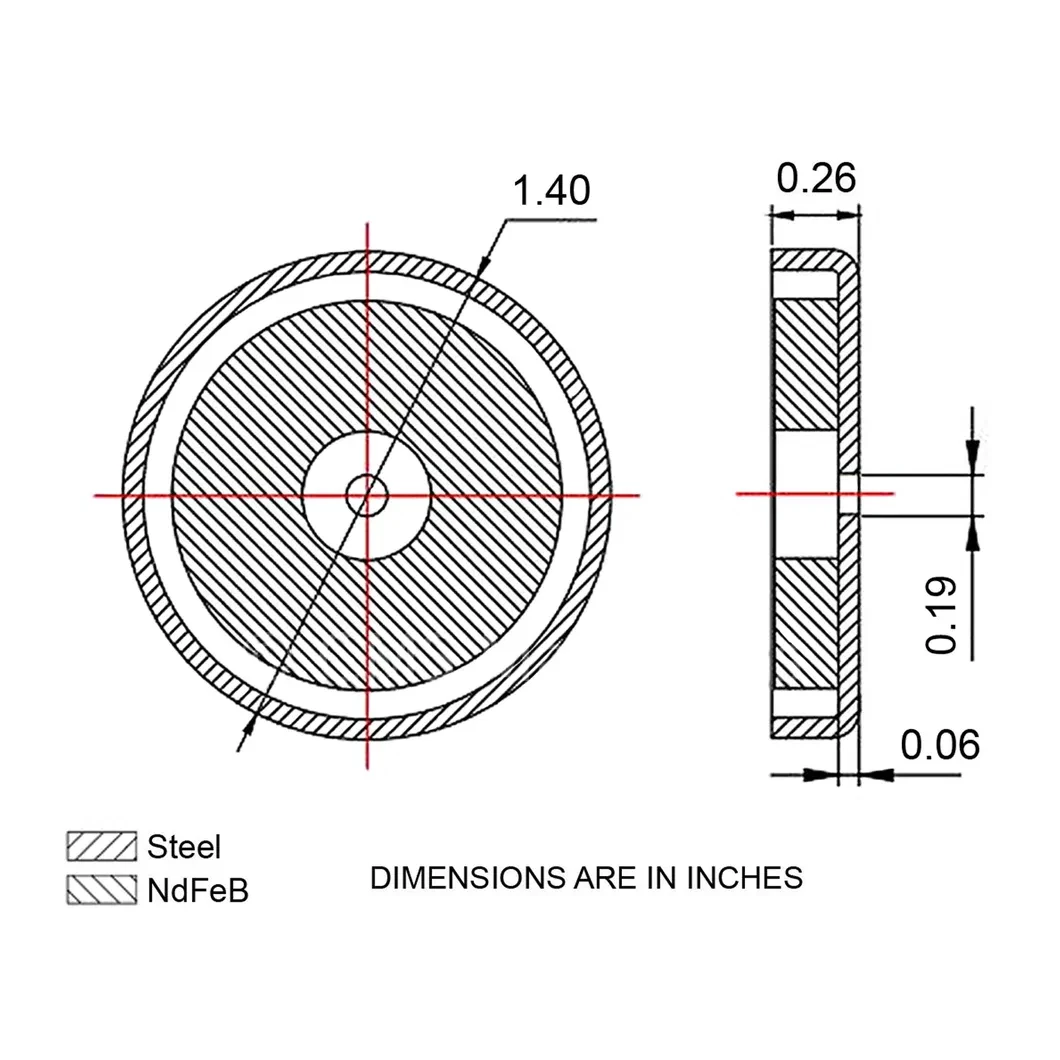

- Shape: Pot magnet with straight hole (Pot Magnet with Straight Hole). This shape gives it advantages in scenarios where a concentrated magnetic field or convenient installation and fixation are required, such as motor and sensor component assembly.

- Color and Appearance: Bright Silver, not only beautiful but also can reflect the good condition of the surface coating. More suitable for applications with appearance requirements.

- Tolerance: ±5%, which reflects the control of manufacturing precision. Ensure the consistency of product performance and size in mass production, and easy cooperation with other components.

NdFeB Magnet Customization Benefits

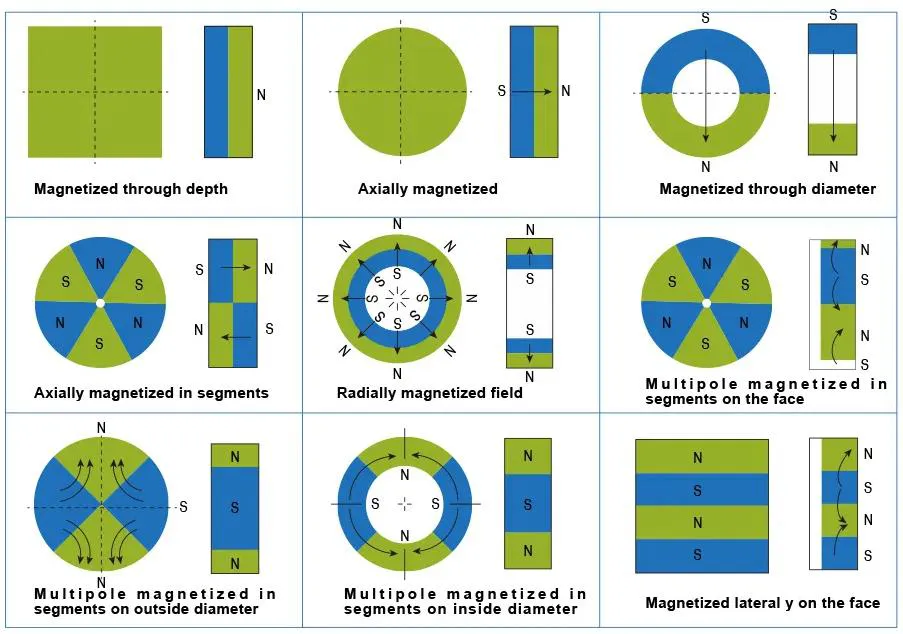

- Shape: Besides the standard pot magnet with straight hole, it can be customized into rings, squares, and irregular shapes according to the customer’s needs, to meet the unique installation and usage requirements of different devices and applications.

- Coating: Different coating materials and processes, such as galvanization, epoxy coating, and Parylene coating, can be customized according to usage environment and special requirements, to enhance the protection in a specific environment and meet different applications.

- Performance: According to the customer’s application requirements, the magnetic properties can be tuned within a certain range, such as adjusting remanence and coercivity, to fit different working environments and device performance requirements.

NdFeB Magnet Bulk Benefits

- Supply Capacity: We have advanced and complete production facilities and an efficient production process, so we have strong mass production capacity. No matter how big the order is, we can guarantee a timely, stable, and sufficient supply.

- Cost-efficient: Through supply chain management, centralized raw material procurement, and adoption of advanced production technology to reduce energy consumption, we control production cost and offer competitive prices to bulk customers.

- Quality Control: We have established a strict and comprehensive quality control system, covering raw material inspection and screening, multi-process detection during production, and final product inspection. So every magnet hasa stable and reliable quality.

NdFeB Magnet Application Scenes

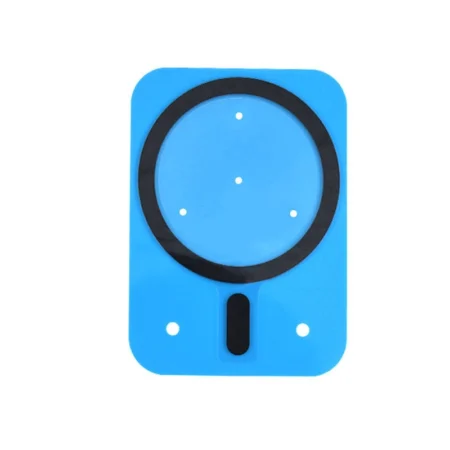

- Electronic Device Manufacturing: Applied in components such as wireless charging modules, speakers, vibration motors, and sensors of consumer electronics products like mobile phones, computers, and tablets, to improve product performance and function.

- Industrial Neodymium Magnets: Used in motors, solenoid valves, magnetic fixtures, and automated transmission equipment, to increase the degree of automation and precision in the production process and facilitate industrial production.

- Medical Equipment Industry: Plays a key role in medical products such as magnetic resonance imaging (MRI) devices, medical sensors, drug delivery systems, and rehabilitation physiotherapy equipment, to provide magnetic support for medical diagnosis and treatment.

- Creative and DIY Projects: Suitable for various creative design and DIY handicraft-making scenarios, such as making magnetic decorations and creative teaching aids, to provide magnetic components for creativity.

NdFeB Magnet Installation and Maintenance

- Installation: During installation, avoid violent collision and improper attraction between magnets to prevent magnet damage or personnel injury. For this pot magnet with a straight hole, you can use appropriate connectors to install and fix it through the straight hole to ensure firm installation and accurate positioning. If needed, we can provide an installation guide and professional technical support.

- Maintenance: In use, keep the magnet away from strong acid, alkali, strong oxidants, and other corrosive substances to prevent coating damage and magnet corrosion. Wipe the surface of the magnet with a clean and soft cloth regularly. If not in use for a long time, store the magnet in a dry and cool environment without strong magnetic field interference and do not stack it with other magnetic materials to prevent magnetic decline or magnetic field disorder.

Summary of Product Advantages

- High Performance: As an N52-grade NdFeB magnet, it has excellent magnetic properties such as high remanence, high coercivity, and a high magnetic energy product, meeting the strict requirements for magnetism in numerous high-end and precision applications.

- Customizability: We offer comprehensive customization services covering aspects such as shape, coating, and performance, fully meeting the diverse and personalized needs of different customers.

- Wide Application: Suitable for a wide range of fields, including electronics, industry, medicine, and creativity, with broad market application prospects, providing reliable magnetic solutions for customers in different industries.

- Reliable Quality: A strict quality control system and advanced production processes ensure stable and reliable product quality, high consistency of magnetic properties, and good performance over the long use.

Frequently Asked Questions—NdFeB Magnet

1.Are you factory/manufacturer or trading company? Why to choice you?

Yes, we are a direct factory manufacturer who owns production lines and workers, and everything is flexible, and you don’t have to worry about paying extra money to the middleman or trader.

2.Can you make our design?

Yes, your designs are welcoming.

3.Are you able to guarantee quality?

Every production process is controlled by professional technicians, and we have a perfect QC system, which has 100% quality inspection before delivery

4.Samples available?

Yes, sampling days:5-7 days, more days if make as your design.

5.How to choose the suitable suction force of the magnet box?

The suction force of magnet box is recommended to be 600-800kg for the production of composite slabs onstable platform, and the use spacing of the magnet box is adjusted according to the heicht of the formwork(generally 1 -1.5meters one piece), in the production on vibration platform,1000kg magnetic box is moresuitable. When producing wall panels, a 1350kg magnet box is suggested; when producing prefabricated beams, columns, or other special-shaped components,1800-2100kg magnet boxes with customized.

6.What is NdFeB Magnets?

When I ask myself, “What is NdFeB magnets?” I think of neodymium-iron-boron magnets. People also call them neodymium or NdFeB magnets. These magnets combine neodymium, iron, and boron, creating the strongest rare-earth magnets available today. Their unique crystal structure, known as Nd2Fe14B, enables them to generate powerful magnetic fields.