High-Performance Samarium Cobalt Magnetic Material丨CORT

Customized Service:OEM&ODM

MOQ:100 PCS

Material:Support customization

Material grade:Support customization

Magnet shape:Support customization

Size:Customized

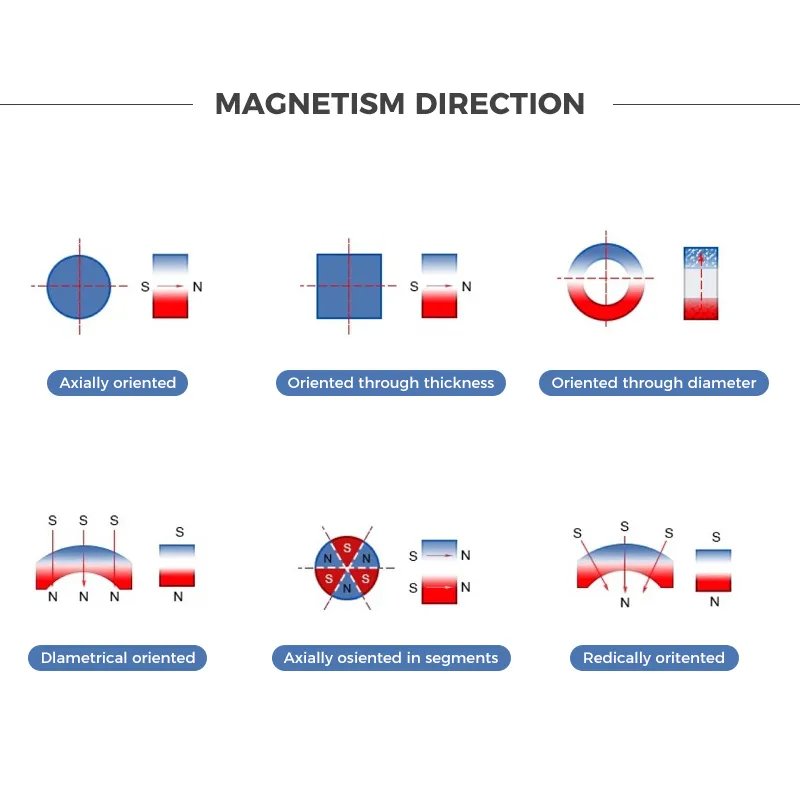

Magnetization direction:Support customization

Samarium Cobalt magnets Product Overview

CORT’s High Performance Samarium Cobalt Magnetic Material is a key magnetic solution for various industries. Samarium cobalt (SmCo) magnets are known for their great properties and are used in applications that require high-performance magnetic components.

Samarium Cobalt magnets Core Materials and Characteristics

- Material Composition: These magnets are made of Sm2Co17, a type of samarium-cobalt alloy. Samarium-cobalt is a high-performance, low-temperature, low-temperature-coefficient permanent magnetic material, consists of samarium, cobalt, and other rare earth elements. It has excellent thermal stability, high magnetic properties, good corrosion resistance, and high resistance to demagnetization.

- Shape Feature: Cup-shaped. This cup-like structure is beneficial in applications where a concave magnetic structure is required, such as in certain motor designs or magnetic assemblies that require a focused magnetic field.

- Magnetic Performance: Bh Max is from 16 mgoe to 32 mgoe. This range allows for selection based on different application requirements for magnetic field strength.

- Size Option: Customizable. We can adjust the dimensions of the cup-shaped magnet, including diameter, depth, and wall thickness, according to the customer’s specific needs to fit different equipment.

- Coating Option: No coating by default, but can be customized. In most applications, the inherent corrosion resistance of SmCo may not require coating. But in a corrosive environment, customized coating such as nickel (Ni), zinc (Zn), or epoxy can be applied to enhance protection.

Samarium Cobalt magnets Application Scenarios

- Speaker Field: As speaker magnets, they generate a stable and strong magnetic field. This interacts with the voice coil to convert electrical signals into sound signals accurately, greatly improving the sound quality of speakers.

- Industrial Field: In industrial applications, they are used in various equipment. For example, in magnetic fixtures, they hold workpieces firmly, ensuring machining accuracy. In magnetic separators, they separate ferromagnetic impurities from materials, safeguarding the normal operation of production lines.

- Motor Field: In motors, SmCo magnets provide a reliable and stable magnetic field. This is crucial for the efficient conversion of electrical energy into mechanical energy, making them suitable for high-performance and demanding motor applications.

- Made to Order: We can customize these magnets according to the customer’s specific needs, including size adjustment and magnetic performance modification. So the magnets will fit perfectly into the application requirements.

Samarium Cobalt magnets Installation and Maintenance

- Installation: Handle the magnets with care during installation to avoid mechanical damage. Align and position the magnets according to the equipment design to optimize the magnetic field performance.

- Maintenance: In normal use, keep the magnets clean. In a harsh environment (such as a corrosive condition), check the magnet regularly for any sign of corrosion or damage. If customized coating is applied, check the coating periodically and take action if damage is found to maintain the magnet’s performance and lifespan.

Samarium Cobalt magnets Product Benefits

- High Performance: Excellent thermal stability, high magnetic properties, good corrosion resistance, high resistance to demagnetization, SmCo magnets perform well in many applications.

- Customization: Size and coating can be customized to fit your application needs.

- Wide Application: Suitable for speaker, industrial, and motor applications.

Frequently Asked Questions—Samarium Cobalt magnets

1. Why cup - shape design for these SmCo magnets?

Cup-shaped design has a unique magnetic field distribution. It can focus the magnetic field to a specific direction or area, which is good for motor design, where a concentrated magnetic field can improve energy conversion efficiency, or magnetic assembly, where a specific magnetic field pattern is required.

2. Why customization magnets coating?

SmCo magnets have good corrosion resistance, but in some corrosive environments (high humidity, acidic, and alkaline), a customization coating can provide extra protection. Coatings like nickel, zinc, and epoxy can prevent the magnet from corroding, extend its service life, and maintain its magnetic performance. Some coatings also provide other benefits, like better adhesion for assembly.

3. Can these SmCo magnets work in high temperature?

Yes, SmCo magnets are suitable for high temperatures. They can work up to 350°C, depending on the grade and permeance coefficient. Excellent thermal stability with low flux density change over temperature makes them a good choice for high-temperature applications like turbo machinery and some industrial heating equipment. But please note that the maximum operating temperature may vary depending on the exact composition and application details, so please consult us for more information.

4. How to determine the Bh Max for my application?

Bh Max value depends on your application requirements. If your application needs a stronger magnetic field like such as a powerful motor or a heavy-duty magnetic separator, you may choose a higher Bh Max value within 16 mgoe – 32 mgoe. If your application only needs a relatively lower magnetic field strength, like some small-scale electronic sensors, you can choosea lower Bh Max value. Our technical team can also give you professional advice based on your application details.