Magnetic Rings for Electronic Applications丨CORT

Customized Service: OEM & ODM

MOQ:100 PCS

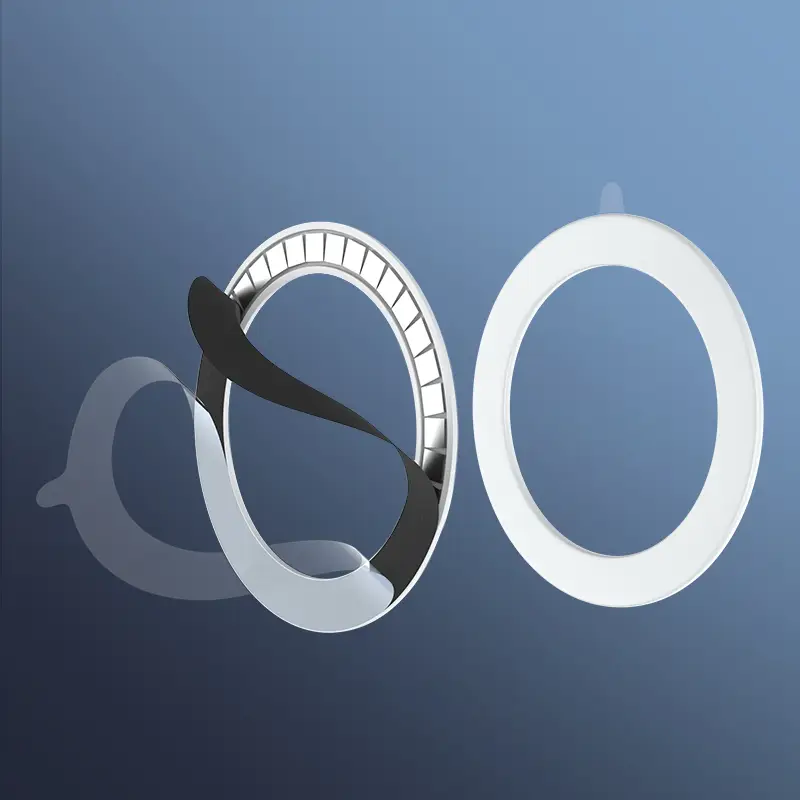

Material code: N52-D54-D46-2.0mm (O-type)

Magnet specifications: W9.84 * 4 * 1.4 watt type

Material code: N52-W9.84 * 4 * 1.4 watt type Zn

Metal Plate specifications: D54.0-D46-0.6mm

Material Code: D54.0-D46.0-0.6- Zn

Magnetic Rings Product Overview

CORT’s Magnetic Rings for Electronic Applications are magnetic components designed for electronic devices. With their special material and structure, they play important roles in optimizing electromagnetic performance in various electronic applications.

It is the best raw material for the MagSafe magnet. If you need stock, CORT MAGNETS can provide stock in various sizes. If you need customization, CORT MAGNETS can also customize your MagSafe magnets based on your parameter information.

Magnetic Rings Core Parameters and Characteristics

Magnetic Rings Material-related

- Magnet Material: N52 material code, high-performance neodymium-iron-boron permanent magnetic material. High magnetic energy product and high coercivity can provide a strong and stable magnetic field. For example, in some electronic devices with high magnetic field requirements, it can ensure stable magnetic flux.

- Metal Coating: Some specifications have Zn (zinc) coating. Zinc coating can enhance the corrosion resistance of the magnetic ring, can be used stably in more environments, and extend the product’s life. For example, in a high-humidity environment, it can prevent the magnetic ring from rust and corrosion.

Magnetic Rings Size Specifications

- Magnet Size: W9.84 4 1.4 watt type. This size determines the magnetic field distribution and strength of the magnetic ring, which can be adapted to the magnetic circuit design of specific electronic devices.

- Metal Plate Size: D54.0 – D46.0 – 0.6mm. This size affects the overall mechanical structure and magnetic shielding performance of the magnetic ring, and plays an important role in the cooperation of the magnetic ring and other electronic components.

- Overall Shape and Dimension Parameters: O – type (ring shape), D54 – D46 – 2.0mm. This shape and dimension can form a closed magnetic circuit, reduce magnetic leakage and improve magnetic utilization efficiency, achieve more efficient electromagnetic conversion, and perform other functions in electronic devices.

Magnetic Rings Application Scenarios

- Power Supply Field: In power supply devices (such as switching power supplies), it can be used as an inductor core. By using its high saturation magnetic induction intensity and low core loss, it can improve the conversion efficiency of the power supply, reduce heat generation, and stabilize the output voltage and current. For example, in computer power supplies and mobile phone chargers, can enhance the performance and stability of the power supply.

- Communication Equipment: Used in components such as filters and transformers of communication equipment. It can suppress electromagnetic interference (EMI), enhance signal purity and transmission stability, and ensure communication quality. For example, in routers and modems, can reduce signal distortion and noise interference.

- Sensor Field: Used with various sensors (such as Hall-effect sensors). Provide a stable magnetic field environment for sensors, so sensors can more accurately detect physical quantities such as magnetic field change, position, and speed. Widely used in sensor systems in automotive electronics and industrial control.

Magnetic Rings Installation and Maintenance

- Installation: Installation should be carried out in accordance with the design requirements and layout of electronic devices. Pay attention to the direction and position of the magnetic ring to ensure that its magnetic circuit is correctly matched with other components. For example, when installed in a power supply circuit, the winding direction of the magnetic ring should meet the circuit design requirements to avoid affecting the performance of the magnetic ring and the normal operation of the device due to improper installation.

- Maintenance: In daily use, keep the surface of the magnetic ring clean and avoid contamination by dust, oil, and other pollutants, which may affect its magnetic performance. Try to avoid exposing the magnetic ring to harsh environments such as high temperature and strong vibration. If the working environment is relatively harsh, regularly check whether the magnetic ring is damaged or has a decline in magnetism, and replace it in a timely manner if necessary.

Magnetic Rings Summary of Product Advantages

- High – performance Magnetic Material: Using high – performance neodymium – iron – boron materials such as N52, it has excellent magnetic properties and can meet the high requirements of electronic devices for magnetic field strength and stability.

- Precise Size Design: Precise size specifications enable the magnetic ring to accurately cooperate with other components of electronic devices, achieving better electromagnetic performance and overall device performance.

- Wide Applicability: Suitable for multiple electronic fields such as power supplies, communications, and sensors, it can meet the diverse needs of different electronic devices.

Frequently Asked Questions—Magnetic Rings

1. Can this magnetic ring be used in high - frequency electronic devices?

Since the material used has certain high-frequency characteristics, it can theoretically be used in some high-frequency electronic devices. However, specific applicability also needs to be determined in combination with the specific high-frequency parameters of the device (such as the operating frequency range and requirements for core loss). It is recommended that you inform us of the detailed parameters of the device so that we can provide you with more accurate advice.

2. What factors affect the service life of the magnetic ring?

The service life of the magnetic ring is mainly affected by environmental factors (such as temperature, humidity, corrosive gases, etc.) and working intensity (such as the magnitude of the current passing through, the frequency of magnetic field changes, etc.). High-temperature, high-humidity, and strongly corrosive environments will accelerate the aging and corrosion of the magnetic ring; high-intensity working conditions, such as long-term large-current and high-frequency magnetic field changes, may lead to a decline in the magnetism and performance of the magnetic ring.

3. Can the magnetic ring be customized according to specific electronic device requirements?

Yes, CORT offers customization services for magnetic rings. We can adjust parameters such as material properties, size, and shape according to your specific electronic device requirements. Whether it’s for adapting to unique magnetic circuit designs or meeting specific performance needs, we are committed to providing you with the most suitable magnetic ring solutions. Please feel free to contact us with your requirements.

4. How does the magnetic ring perform in terms of electromagnetic compatibility (EMC) in complex electronic systems?

Our magnetic rings are designed with EMC in mind. In complex electronic systems, they can effectively suppress electromagnetic interference, filter out unwanted electromagnetic signals, and enhance the overall electromagnetic compatibility. Through precise material selection and structural design, they can help maintain the stability and normal operation of electronic systems, reducing the risk of signal interference and equipment malfunctions.