Neodymium Block Magnets-Arc Shaped for Industrial丨CORT

Neodymium Block Magnets Product Overview

Get into our Neodymium Block Magnets! These are high-performance, arc-shaped magnets that deliver great magnetic power and reliability. Made from top-quality NdFeB material and coated with nickel, they are designed for applications where a unique arc shape and strong magnetic force are required. Whether used in electronic products, industrial setups, or motors, they always perform well.

Neodymium Block Magnets Core Specifications

- Neodymium magnet grades: N52 or customizable grades. This means the magnets have strong magnetic properties to handle various tasks that demand high magnetic attraction.

- Shape: Arc-shaped. The arc design offers a special magnetic field distribution, ideal for integration into motors and industrial machinery.

- Material: NdFeB Magnet. As a powerful magnetic material, NdFeB (neodymium iron boron magnets) provides a high magnetic energy product, generates a strong magnetic field in a compact block form.

- Coating: Nickel coating. This coating offers excellent corrosion resistance, protects the magnet from environmental factors like moisture and chemicals, and gives it a smooth and professional look.

- Tolerance: +/- 0.05mm. This high precision ensures the magnets will fit and function perfectly in your applications, from precise electronic components to large-scale industrial projects.

- Size: Customized. Whether you need specific-sized arc blocks for electronic devices or industrial applications, we can adjust the dimensions to meet your exact requirements.

Neodymium Block Magnets Product Advantages

- Strong Magnetism with Arc Design: N52 grade combined with arc shape provides strong and uniquely distributed magnetic pull. Ideal for tasks like providing a magnetic field in motors or precise positioning in industrial magnet applications.

- Durable Nickel Coating: Nickel coating forms a protective barrier against corrosion, extending the magnet’s life. Suitable for use in harsh environments like humid industrial areas or corrosive electronic setups.

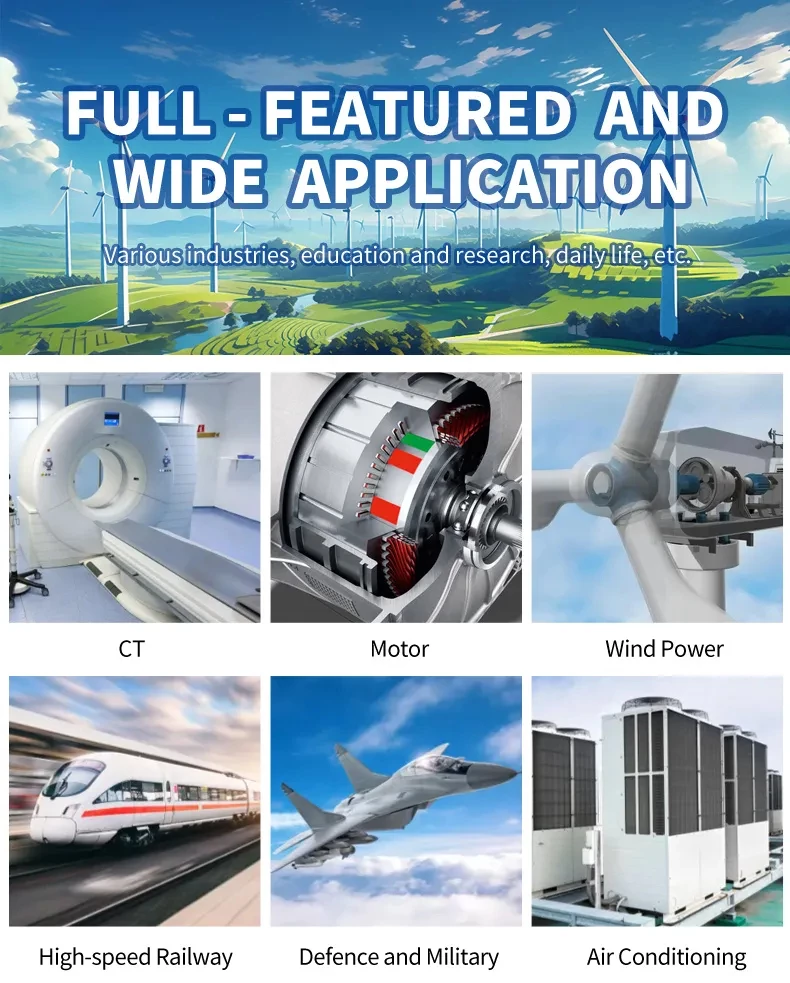

- Versatile Application: Arc-shaped neodymium block magnets are highly versatile. Can be used in electronic products as key magnetic components, in industrial magnets for lifting or holding tasks, and in motors to provide the necessary magnetic force for efficient operation.

Neodymium Block Magnets Application Scenarios

- Electronic Products: In precision sensors and actuators of electronic devices, these arc-shaped neodymium block magnets can be used to provide a magnetic field. Small in size (when customized) and strong in magnetism, they are perfect for these high-precision applications.

- Industrial Neodymium Magnets: In industrial applications, these magnets can be used in magnetic lifting equipment for curved or irregularly shaped metal parts or in magnetic fixtures to hold workpieces during the manufacturing process. This ensures efficient material handling and precise manufacturing.

- Motor Magnet: In motors, especially those with special design requirements, these arc-shaped neodymium block magnets are key. They provide the magnetic force for rotation, and their arc shape can be customized to fit the motor’s design, resulting in more powerful and energy-efficient motors.

Neodymium Block Magnets Customization Services

Every project is unique. That’s why we offer customization for our Neodymium Block Magnets.If you need custom neodymium magnets, you can contact us and we will provide you with a professional one-stop customized solution

Neodymium Block Magnets Customizable Options

- Size: Need small arc blocks for micro-electronic devices or large ones for industrial applications? We can adjust the inner and outer radii, as well as the thickness, to fit your needs.

- Grade: N52 is standard, but we can provide other grades of neodymium magnets to match the magnetic strength requirements of your project.

- Tolerance: We can maintain a tolerance of +/- 0.05mm as standard, but we also offer customized tolerance levels if your application requires different precision standards.

Neodymium Block Magnets Customization Process

- Contact Us: Reach out to our team with your requirements. Use our online contact form, email us, or give us a call. Our sales and engineering team will work closely with you to understand your needs in detail.

- Design and Quote: Based on your requirements, our engineers will design a custom solution. We will then send you a detailed quote including cost, lead time, and all other relevant information.

- Sample Production (Optional): If you want to test the custom magnets before mass production, we can produce a small batch of sample magnets for your approval. This allows you to verify that the custom magnets meet your expectations.

- Mass Production: Once you approve the sample (or if you choose to skip the sample stage), we will start mass production. Our state-of-the-art production facilities ensure the magnets are produced to the highest quality standards.

- Shipping: We will ship the custom magnets to your location on time and in perfect condition.

Frequently Asked Questions—Neodymium Block Magnets

1: Can the arc shape of these neodymium block magnets be adjusted to fit non - standard motor designs?

Absolutely! We offer fully customized arc shapes. Whether your motor has unique curvature or radius requirements, our engineering team can design and produce neodymium block magnets to perfectly match non-standard motor layouts, ensuring seamless integration.

2: How does the nickel coating affect the magnet’s compatibility with food - grade industrial applications?

The nickel coating is non-reactive and meets general industry standards for cleanliness. For strict food-grade requirements, we can further validate the coating or discuss alternative food-safe coatings (like epoxy) to ensure full compliance with hygiene regulations.

3: Do these arc magnets retain their magnetic strength after long - term exposure to vibration in industrial machinery?

Yes. Neodymium magnets are inherently resistant to vibration-induced demagnetization under normal operating conditions. Our N52 grade, combined with precise manufacturing, ensures stable magnetic performance even in high-vibration industrial environments.

4: Can I order a mix of N52 and customized lower - grade magnets in the same batch for cost - effective hybrid applications?

Definitely! We support mixed-grade orders. This allows you to use high-strength N52 magnets in critical areas and lower-grade (yet still powerful) customized magnets in less demanding sections, optimizing both performance and cost for hybrid industrial or electronic projects.

5: How does the tolerance of +/-0.05mm impact the alignment of multiple arc magnets in large - scale industrial setups?

The tight +/-0.05mm tolerance ensures consistent alignment across multiple magnets. In large-scale setups (like industrial motors or magnetic conveyors), this precision minimizes magnetic field distortion, resulting in smoother operation and more reliable performance.

6.What is NdFeB Magnets?

When I ask myself, “What is NdFeB magnets?” I think of neodymium-iron-boron magnets. People also call them neodymium or NdFeB magnets. These magnets combine neodymium, iron, and boron, creating the strongest rare-earth magnets available today. Their unique crystal structure, known as Nd2Fe14B, enables them to generate powerful magnetic fields.