Neodymium Disc Magnets – N42 Grade for Diverse Applications丨CORT

Shape: Disc

Grade: N42

Composition: neodymium magnet

Coating: Nickel or Customized

Certificate: CE/SGS/ISO/IATF 16949/RoHS/Reach

Tolerance:+/-0.05mm or Customized

neodymium disc magnets Product Description

Our neodymium disc magnets – small but mighty magnetic components made from high-quality neodymium. N42 grade, these disc-shaped magnets are strong. Nickel coating (or customized coatings) with precise tolerance control (±0.05mm or customized) and various sizes (D X H, e.g., D8 X 1mm, D10 X 3mm, D15 X 1.5mm). CE/SGS/ISO/IATF 16949/RoHS/Reach certified for home use to industrial applications.

Key Features

- Neodymium magnet grades: N42. Strong magnetic pull for applications where space is limited but powerful magnetism is required.

- Shape: Disc. Simple and versatile disc shape for easy integration into various projects from DIY home use to complex industrial assemblies.

- Material: Neodymium magnet. High quality neodymium material for excellent magnetic properties.

- Coating: Nickel or customized. Standard nickel coating for good corrosion resistance and smooth finish. Customized coatings available for environmental or aesthetic requirements.

- Certificate: CE/SGS/ISO/IATF 16949/RoHS/Reach. Our neodymium disc magnets meet strict quality, safety and environmental standards.

- Tolerance: ±05mm or customized. Precise tolerance control for perfect fit into your projects whether for high precision industrial applications or DIY home use.

- Size: D X H (e.g., D8 X 1mm, D10 X 3mm, D15 X 1.5mm). Various standard sizes available, custom sizes can be produced to meet your needs.

neodymium disc magnets Benefits

- Strong Magnetic Field: N42 grade, these neodymium disc magnets have strong magnetic field in small disc shape. Suitable for holding, positioning or aligning components in various projects.

- Coating Options: Standard nickel coating for good corrosion protection, customized coatings for specific environments (e.g., harsh industrial or aesthetically demanding home projects).

- Tolerance Control: ±05mm or customized, our strict tolerance control ensures these neodymium disc magnets will fit into your design. Important for applications where small deviation can affect performance.

- Various Sizes: Various standard sizes and custom production available, these magnets can fit almost any project, from small DIY to large industrial applications.

- Certified: CE/SGS/ISO/IATF 16949/RoHS/Reach certified.

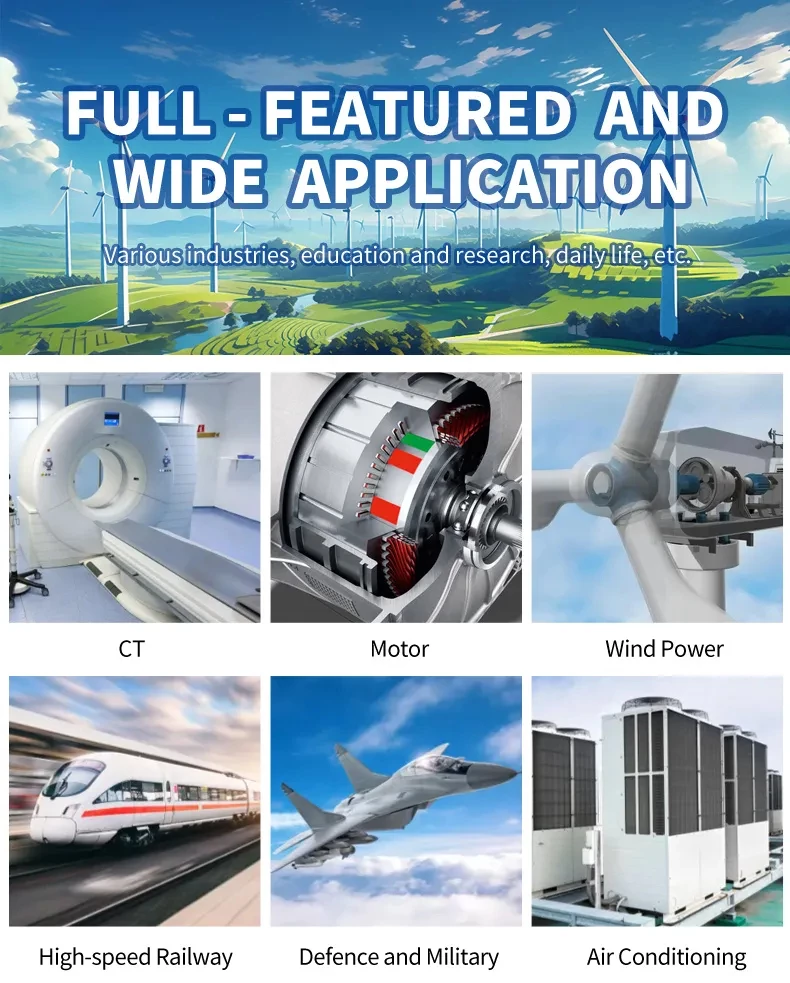

Application Examples

- Home Use: For home projects, these neodymium disc magnets can be used to hold notes on the fridge, create custom magnetic organizers, or make DIY crafts. Small and strong, perfect for adding functionality to everyday items.

- Industrial Applications: In industry, Industrial Neodymium Magnets can be used in machinery for component holding, positioning, or as part of magnetic assemblies. Precise tolerance and strong magnetic performance for industrial use.

- DIY Projects: For DIY enthusiasts, these neodymium disc magnets offer endless possibilities. Use in model building, custom magnetic tools, or any project that requires a small but powerful magnet.

- Electronics: In electronics, these magnets can be used for sensor activation, component alignment, or as part of magnetic connectors. Small enough to fit in compact electronic designs.

Customization Services

We know that different projects have different requirements. That’s why we offer customization services for our neodymium disc magnets.

If you need custom neodymium magnets, you can contact us and we will provide you with a professional one-stop customized solution

Customizable Options

- Coating: In addition to the standard nickel coating, we can provide other coating options like zinc, epoxy or gold plating. Different levels of corrosion resistance, aesthetic finishes, or compatibility with specific environments.

- Tolerance: If your project requires a tighter or different tolerance than our standard ±05mm, we can adjust the manufacturing process to meet your precision requirements.

- Size: While we have standard sizes, we can also produce custom-sized neodymium disc magnets to fit your project needs. Small for a delicate DIY project or large for an industrial application, we can accommodate.

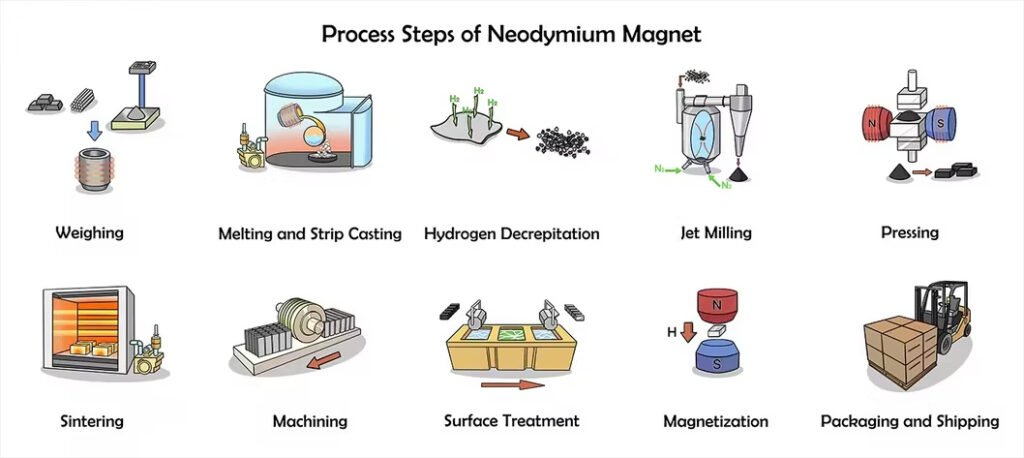

Customization Process

- Contact Us: Contact our team through our website, email, or phone. Share your project details, including the coating, tolerance, size, and application of the neodymium disc magnets.

- Design and Quote: Our team will work with you to design the custom solution. We will then send you a detailed quote including the price, lead time, and other relevant information.

- Sample Production (Optional): If you want to test the custom magnets before mass production, we can produce a small batch for your evaluation. This way, you can verify that the magnets meet your expectations in terms of performance and fit.

- Mass Production: Once you approve the sample (or if you choose to skip the sample stage), we will proceed with mass production. Our advanced facilities will produce the neodymium disc magnets to the highest quality.

- Delivery: We will ship the custom magnets to your location on time and in perfect condition. We ship worldwide to our international customers.

Frequently Asked Questions—neodymium disc magnets

1.Are these neodymium disc magnets safe for home use?

Yes, but they should be kept away from children and individuals with pacemakers. As with any small magnet, ingestion can be dangerous, so proper precautions should be taken, especially in households with young children.

2.Can these magnets be used in outdoor applications?

The standard nickel coating provides some corrosion resistance, but for prolonged outdoor use in harsh environments, customized coatings (such as epoxy) may be recommended. Contact our team to discuss your specific outdoor application requirements.

3.What is the maximum operating temperature for these neodymium disc magnets?

The maximum operating temperature depends on the grade and coating. For N42 grade with nickel coating, the recommended maximum operating temperature is around 80°C. For higher temperature applications, we can provide magnets with modified grades or coatings. Contact our team for more information.

4.How do I choose the right size of neodymium disc magnet for my project?

Consider the required magnetic force, the space available in your project, and the weight of the objects you need to hold or move. Our team can also provide guidance based on your project details.

5.Do you offer bulk pricing for large orders of neodymium disc magnets?

Yes, we offer competitive bulk pricing for large orders. Contact our sales team with your order quantity and requirements to get a customized quote.

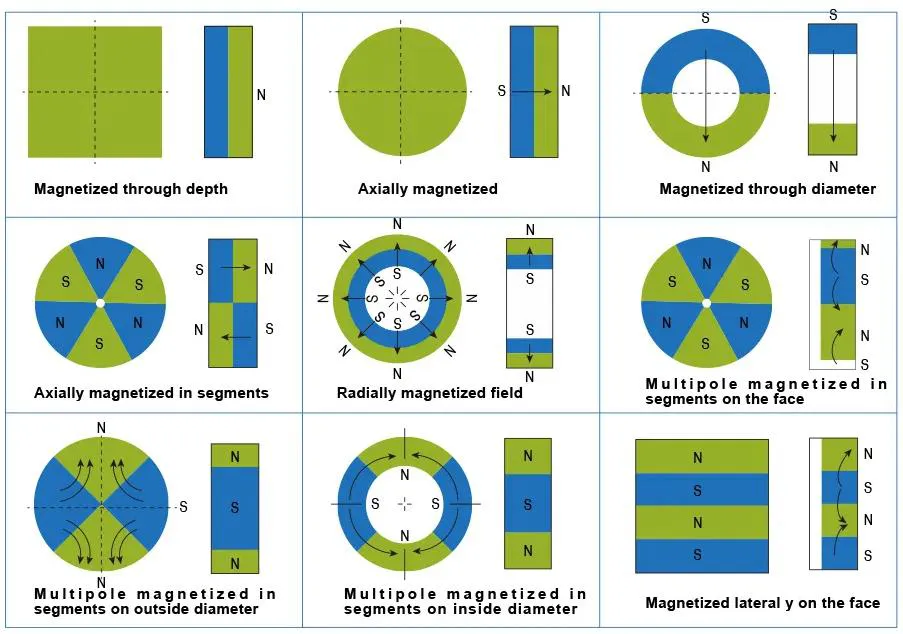

6.What is NdFeB Magnets

When I ask myself, “What is NdFeB magnets?” I think of neodymium-iron-boron magnets. People also call them neodymium or NdFeB magnets. These magnets combine neodymium, iron, and boron, creating the strongest rare-earth magnets available today. Their unique crystal structure, known as Nd2Fe14B, enables them to generate powerful magnetic fields.