Neodymium Ring Magnets – The best choice of magnets丨CORT

Shape:Disc

Composition:Neodymium Magnet

Grade:36H

Size:Customized

Tolerance:+/-0.05mm or Customized

neodymium ring magnets Product Overview

Our neodymium ring magnets are precision-engineered magnetic components that utilise the properties of neodymium magnet material. With a grade of 36H, these disc-shaped magnets offer high magnetic strength and stability. The disc form factor makes them very versatile for use in a wide range of applications, from miniature electronic devices to large industrial machinery. Whether you need standard-sized magnets for everyday use or fully customised solutions for your unique project, these neodymium ring magnets are designed to perform.

neodymium ring magnets Key Specifications

- Material: Made from high-quality neodymium magnet material, these magnets benefit from the high magnetic energy product of neodymium. This means strong magnetic attraction in a small physical size, perfect for space-constrained applications.

- Grade: 36H grade, these magnets have excellent resistance to demagnetisation. This grade means they can withstand moderately challenging environments and are suitable for long-term use in many applications.

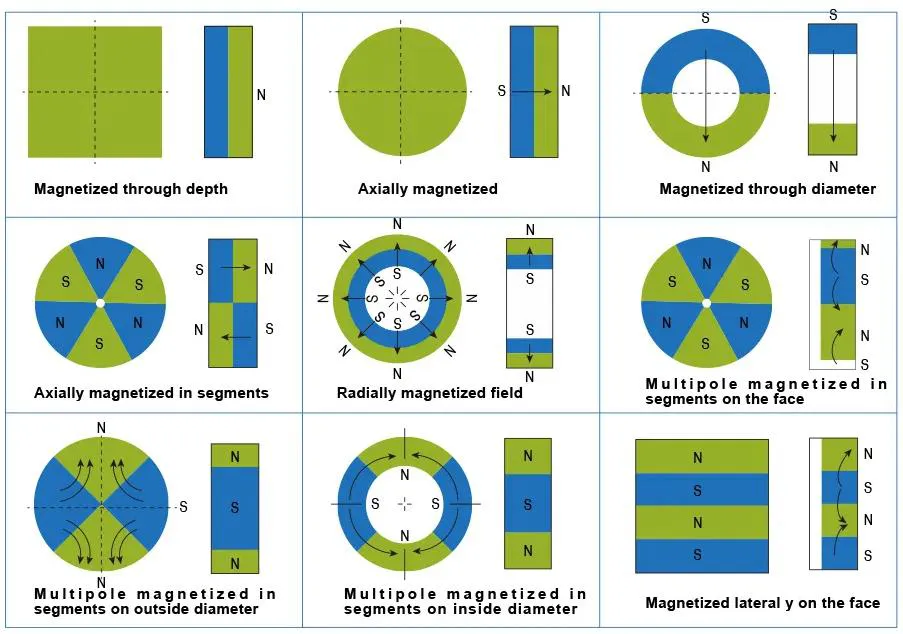

- Shape: The disc shape is a popular and widely used geometry. It provides a relatively uniform magnetic field distribution across its surface, ideal for applications such as sensor activation, speaker magnetism, and industrial holding.

- Size: We can customise to any size you require. Whether you need a small magnet for a precision electronic component (e.g., in a smartphone sensor) or a large magnet for an industrial motor, our manufacturing process can be tailored to produce the exact size you need.

- Tolerance: Our standard tolerance is +/-0.05mm, so the magnets will fit your design precisely. For applications that require even tighter tolerance, we can customise to your project’s requirements so they fit seamlessly.

- Coatings

- Ni (Nickel): A cost-effective coating that provides good corrosion resistance and a smooth finish.

- Ni – Cu – Ni (Nickel-Copper-Nickel): Better corrosion protection than single-layer nickel, ideal for harsh environments.

- Zn(Cr3+) (Zinc with trivalent chromium): Excellent corrosion resistance and environmentally friendly.

- Tin: Suitable for applications that require solderability and good corrosion resistance.* Epoxy: A tough, protective coating that can withstand extreme environments, high humidity, and chemical exposure.

- Ni-AG (Nickel-Silver): Nickel corrosion resistance with silver electrical conductivity, for specific electronic applications.

- Ni-Au (Nickel-Gold): High corrosion resistance and high electrical conductivity, used in high-end electronic and aerospace applications.

Product Features

- High Pull: 36H grade neodymium material means these disc magnets have high magnetic strength. Perfect for applications that require a strong magnetic force, like motor magnets for efficient energy conversion or industrial holding fixtures for material handling.

- Customizable: Every aspect of these magnets, size and tolerance to coating, can be customized. Get magnets that fit your application, whether it’s a delicate electronic product that requires a precise fitting magnet or a heavy-duty industrial magnet that can withstand harsh conditions.

- Corrosion Resistant (with Coatings): The various coating options provide excellent corrosion protection. This extends the life of the magnets even in harsh environments. For example, the epoxy coating can protect the magnets from moisture and chemicals in industrial settings, while the Ni-Au coating is perfect for high-end electronic applications where corrosion resistance and conductivity are critical.

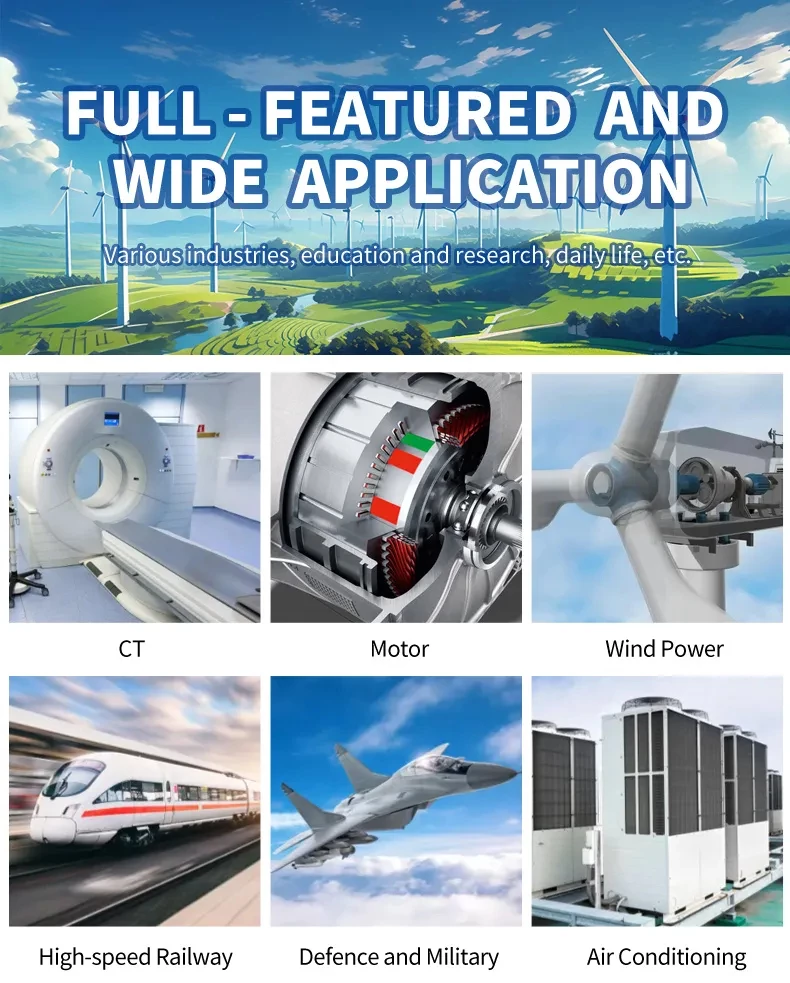

- Versatile Use :The disc shape and customizability of these magnets can be used in many applications:

- Electronic Products: Can be used in components like sensors (position detection), actuators (small-scale movement), and cameras (image stabilization) in smartphones, tablets, and laptops.

- Speaker Magnets: Create a strong magnetic field that interacts with the speaker coil to produce high-quality sound. Their compact size allows for smaller and more efficient speakers.

- Industrial Magnets: For holding, lifting, and separating ferromagnetic materials. Can be used in magnetic clamps for welding, magnetic separators for removing metal contaminants from fluids, and lifting magnets for handling heavy steel parts.

- Motor Magnets: Contribute to the creation of the magnetic field in electric motors, increasing motor efficiency and performance. Suitable for many types of motors, from small hobby motors to large industrial motors.

neodymium ring magnets Customization Services

We know that different projects have different requirements. That’s why we offer customization services for our neodymium ring magnets. If you need custom neodymium magnets, please contact us, and we will provide you with a one-stop customized solution

Size Customization

- Process: Provide us with the desired diameter and thickness of the disc magnet. Our engineering team will design the production process to manufacture magnets of the specified size. We utilize advanced manufacturing techniques to ensure that the size tolerance is maintained as per your requirements.

- Applications: This is particularly useful for applications where space is limited, such as in miniature electronic devices, or where a specific size is required to fit an existing design, such as in custom-built industrial machinery.

Tolerance Customization

- Process: If your application requires a tolerance different from our standard +/-0.05mm, inform us. We can adjust our manufacturing and quality control processes to achieve the desired tolerance level. This may involve additional precision machining and inspection steps.

- Applications: In high-precision applications like aerospace components or medical devices, where even the smallest deviation can affect performance, customized tolerance is essential.

Coating Customization

- Process: Select from our range of coating options based on your application’s environmental and performance requirements. Our coating process is carefully controlled to ensure uniform coverage and adherence. We can also provide additional testing for coating integrity if needed.

- Applications: For example, if you need a magnet for use in a marine environment, we can recommend and apply a coating with high corrosion resistance, such as Ni – Cu – Ni or epoxy. If you need a magnet for an electronic application where solderability is required, a tin coating would be appropriate.

Ordering Process

Inquiry: Contact our sales team via email, phone, or our website to discuss your requirements, including size, grade, coating, tolerance, and application.

Quotation: We will provide you with a detailed quotation based on your requirements, including price, lead time, and other relevant information.

Sample Order (Optional): If you need to test a sample before placing a bulk order, we can produce a sample for you. This allows you to verify the quality and performance of our neodymium ring magnets.

Bulk Order: Once you are satisfied with the sample (or if you choose to skip the sample stage), you can place your bulk order. We will confirm the order details and schedule production.

Delivery: We offer global shipping options to ensure that your order reaches you on time. Our shipping partners are reliable and can provide tracking information so that you can monitor the progress of your shipment. We also take great care in packaging the magnets to prevent damage during transit.

Frequently Asked Questions—neodymium ring magnets

1. What is the maximum operating temperature for these neodymium ring magnets?

For grade 36H, the maximum operating temperature is typically around 120°C. However, if higher temperature resistance is required, we can recommend alternative grades or coatings.

2. Can these magnets be used in a humid environment?

Yes, but the choice of coating is important. Coatings like Ni – Cu – Ni, epoxy, or Zn(Cr3+) provide excellent corrosion resistance in humid environments. We can help you select the most suitable coating for your specific environmental conditions.

3. How do I determine the right size and grade for my application?

Our sales and engineering team are available to assist you. Provide us with details about your application, including the required magnetic force, operating environment, and any space constraints. We will then recommend the appropriate size and grade of neodymium disc magnet for your needs.

4. Are these magnets recyclable?

Neodymium ring magnets contain rare earth materials and can be recycled. However, the recycling process requires specialized facilities. We recommend contacting a local recycling center or a company that specializes in rare earth magnet recycling for proper disposal.

5. What is the lead time for a custom order?

The lead time for a custom order depends on the complexity of the customization (size, tolerance, coating) and the order quantity. Typically, for small to medium-sized custom orders, the lead time is between 2 – 4 weeks. For large-volume or highly complex orders, it may take longer. We will provide you with an accurate lead time during the quotation process.

6.What Is NdFeB Magnets?

When I ask myself, “What is NdFeB magnets?” I think of neodymium-iron-boron magnets. People also call them neodymium or NdFeB magnets. These magnets combine neodymium, iron, and boron, creating the strongest rare-earth magnets available today. Their unique crystal structure, known as Nd2Fe14B, enables them to generate powerful magnetic fields.