Ring Alnico Magnet 8 High-Precision Permanent Magnet丨CORT

Ring Alnico Magnet Product Specification Table

| Parameter | Details |

|---|---|

| Material Grade | Alnico 8 |

| Magnetic Properties | Br: 0.7-0.9 T Hcb: 110-138 kA/m HcJ: 112-152 kA/m (BH)max: 38-48 kJ/m³ |

| Working Temperature Range | ≤550℃ (Curie temperature: 860℃) |

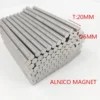

| Ring Dimensions | Outer Diameter: 3-240 mm Inner Diameter: 1-200 mm Thickness: 1-80 mm Tolerance: ±0.05 mm |

| Coating Options | Nickel plating (5-20μm thickness) – Barrel plating: Salt spray test ≤48h – Rack plating: Salt spray test ≤16h |

| Magnetization Direction | Axial, Radial, or Diametrical |

| Applications | Speaker magnets, Industrial sensors, Motor components, Solenoids, Precision instruments |

Ring Alnico Magnet Detailed Features

Optimized Ring Design

- Uniform Magnetic Field: Circular geometry provides symmetrical magnetic flux distribution, ideal for sensors and transducers

- Precision Tolerance: Maintains ±0.05mm dimensional accuracy for critical assembly applications

- Versatile Sizing: Available in an extensive size range (OD 3-240mm) to meet diverse industrial requirements

Superior Magnetic Performance

- High Coercivity: 112-152 kA/m intrinsic coercivity ensures excellent resistance to demagnetization

- Energy Efficiency: 38-48 kJ/m³ maximum energy product delivers optimal power-to-size ratio

- Stable Temperature Characteristics: Minimal performance variation across the operating range with -0.025%/℃ Br temperature coefficient

Extreme Environment Adaptability

- Ultra-high Temperature Operation: Maintains stability at temperatures up to 550℃, suitable for aerospace and automotive engine environments

- Corrosion Resistance: Nickel coating protects against harsh industrial conditions

- Mechanical Durability: High compressive strength (735 MPa) and hardness (650 HV) for demanding applications

Advanced Manufacturing Capabilities

- Dual Production Processes: Available in both cast (complex shapes) and sintered (high precision) versions

- Custom Magnetization Patterns: Supports multi-pole and radial magnetization for specialized motor designs

- Tight Tolerance Control: Precision grinding ensures consistent performance across production batches

Acoustic Engineering

- High-end Speakers: Provide clear, distortion-free sound reproduction with a stable magnetic field

- Microphones: Maintains sensitivity in high-temperature audio equipment

- Guitar Pickups: Delivers warm, vintage tone characteristics preferred by musicians

Industrial Automation

- Position Sensors: Precise magnetic field enables accurate linear and rotational position detection

- Flow Meters: Stable performance in high-temperature fluid monitoring applications

- Solenoid Valves: Fast response time for critical control systems

Automotive & Aerospace

- Engine Sensors: Withstands extreme under-hood temperatures up to 550℃

- Actuators: Reliable performance in aircraft and spacecraft control systems

- Navigation Systems: Stable magnetic reference in precision guidance equipment

Ring Alnico Magnet Product Advantage Summary

Ring Alnico 8 magnet combines exceptional thermal stability, high coercivity, and precision ring geometry to deliver superior performance in demanding applications. Its ability to operate at 550℃ while maintaining magnetic integrity makes it ideal for environments where other magnets fail. The versatile size range and customizable magnetization options ensure optimal integration into motors, sensors, and acoustic devices. With strict tolerance control and durable nickel coating, this ring magnet provides reliable, long-lasting service in industrial, automotive, and aerospace applications where precision and durability are critical.

Ring Alnico Magnet Technical Parameters Table

| Parameter Item | Specification Range | Testing Standard |

|---|---|---|

| Material Composition | Al-Ni-Co-Cu-Fe alloy | ASTM A801 |

| Remanence (Br) | 1.0-1.4T | IEC 60404-5 |

| Coercivity (Hc) | 350-500 Oe | IEC 60404-5 |

| Operating Temperature | -40°C ~ +550°C | ISO 9001:2015 |

| Density | 7.0-7.4 g/cm³ | ASTM B328 |

| Hardness (Hv) | 450-550 | ISO 6507-1 |

| Thermal Expansion Coefficient | 11×10⁻⁶/°C (20-200°C) | ASTM E228 |

Frequently Asked Questions—Ring Alnico Magnet

1. How does Ring Alnico 8 compare to neodymium ring magnets?

While neodymium magnets offer higher energy density, Ring Alnico 8 provides superior temperature stability (550℃ vs. 150℃ for neodymium) and better corrosion resistance without requiring heavy coating.

2.What magnetization direction is recommended for motor applications?

Radial magnetization is typically recommended for electric motor stators, providing optimal flux distribution and torque output.

3. Can custom sizes beyond the standard range be produced?

Yes, we offer custom manufacturing for specialized applications with outer diameters up to 300mm and custom inner diameter-to-outer diameter ratios.

4.What is the typical lead time for custom Ring Alnico 8 magnets?

Standard sizes ship within 7-10 days. Custom designs require 15-20 days for tooling and production, depending on complexity.