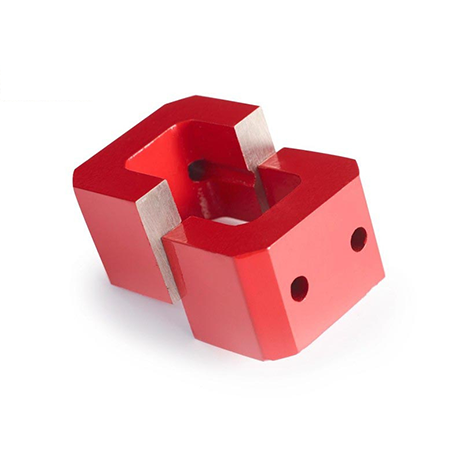

Sintered AlNiCo Magnet Custom Polished U-Shaped Magnets丨CORT

Sintered AlNiCo Magnet Product Overview

Sintered AlNiCo Magnet Technical Specifications

| Parameter | Specification |

|---|---|

| Material | Sintered AlNiCo alloy |

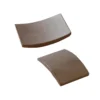

| Shape | Customizable U-shapes and complex geometries |

| Coating | Polished surface finish |

| Tolerance | ±0.1 mm |

| Magnetization Direction | Axial and diametrical options |

| Typical Magnetic Properties | Br: 1.0-1.4 T, Hc: 350-500 Oe |

| Mechanical Strength | Superior to cast AlNiCo products |

| Operating Temperature | -40°C to +550°C |

| Size Range | Typically smaller sizes (customizable) |

Sintering Process Advantages

- Sintered AlNiCo Magnet manufacturing involves compacting fine AlNiCo powder under high pressure, followed by controlled sintering. This process offers:

- Tighter Dimensional Tolerances: ±0.1mm precision for critical applications

- Complex Geometries: Capability to produce intricate shapes and configurations

- Enhanced Mechanical Strength: Improved durability compared to cast alternatives

- Consistent Material Structure: Homogeneous grain structure for reliable performance

- Cost-Effective Production: Efficient manufacturing for small to medium volumes

- Speaker Systems: Precision magnetic components for high-fidelity audio equipment

- Industrial Machinery: Positioning devices, sensors, and magnetic clamps requiring tight tolerances

- Motor Assemblies: Compact motor components where dimensional accuracy is critical

- Automotive Electronics: Custom magnetic solutions for specialized automotive applications

- Instrumentation: Precision measurement equipment requiring stable magnetic fields

- Sintered AlNiCo Magnet offers extensive customization options to meet specific application requirements:

- Shape Customization: U-shapes, horseshoes, and complex geometries tailored to your specifications

- Size Options: Small to medium sizes with tight dimensional control

- Magnetization Patterns: Axial, diametrical, or custom magnetization directions

- Surface Finishes: Polished standard finish or specialized coatings available upon request

- Tolerance Levels: Standard ±0.1mm or enhanced precision options for critical applications

- Our Sintered AlNiCo Magnet manufacturing follows strict quality control procedures:

- Raw Material Inspection

- Powder purity verification (>99.9%)

- Particle size distribution analysis (3-5μm range)

- Alloy composition testing

- In-Process Quality Checks

- Green compact density measurement

- Sintering temperature and atmosphere monitoring

- Dimensional inspection after sintering

- Final Product Testing

- Magnetic property measurement per IEC 60404-5

- Dimensional verification using coordinate measuring machine (±0.01mm precision)

- Surface finish inspection (Ra < 0.8μm for polished surfaces)

- Mechanical strength testing (transverse rupture strength)

| Parameter Item | Specification Range | Testing Standard |

|---|---|---|

| Material Composition | Al-Ni-Co-Cu-Fe alloy | ASTM A801 |

| Remanence (Br) | 1.0-1.4T | IEC 60404-5 |

| Coercivity (Hc) | 350-500 Oe | IEC 60404-5 |

| Operating Temperature | -40°C ~ +550°C | ISO 9001:2015 |

| Density | 7.0-7.4 g/cm³ | ASTM B328 |

| Hardness (Hv) | 450-550 | ISO 6507-1 |

| Thermal Expansion Coefficient | 11×10⁻⁶/°C (20-200°C) | ASTM E228 |

Frequently Asked Questions—Sintered AlNiCo Magnet

1. What are the main performance differences between Sintered AlNiCo Magnet and cast AlNiCo magnets?

Sintered AlNiCo Magnet offers tighter dimensional tolerances (±0.1mm vs. ±0.5mm for cast), superior mechanical strength, and better surface finish. Cast AlNiCo typically provides slightly higher magnetic properties but with larger size capabilities and lower production costs for high volumes.

2. What is the maximum size limitation for Sintered AlNiCo Magnet?

Sintered AlNiCo Magnet is generally limited to smaller sizes, typically with maximum dimensions of 100mm in any direction. For larger components, cast AlNiCo may be more suitable. We can provide specific size recommendations based on your design requirements.

3. How to choose between axial and diametrical magnetization for Sintered AlNiCo Magnet?

Axial magnetization (magnetic poles on opposite flat surfaces) is ideal for most flat or disc-shaped Sintered AlNiCo Magnet applications. Diametrical magnetization (poles on opposite sides of a cylinder) works best for rotating applications like sensors and encoders. Our engineering team can help determine the optimal magnetization pattern for your specific application.

4. What surface treatment options are available for Sintered AlNiCo Magnet?

Standard finish is polished (Ra < 0.8μm) with natural oxide layer. Optional treatments include nickel plating (5-10μm), zinc plating, or epoxy coating for enhanced corrosion resistance. The polished finish provides excellent corrosion resistance in most environments, making additional coatings unnecessary for many applications.

5. Can you provide magnetic performance test reports for Sintered AlNiCo Magnet?

- Magnetic properties (Br, Hc, BHmax) measured per IEC 60404-5

- Dimensional inspection report with full coordinate data

- Material certification and traceability information

- Optional environmental test results (salt spray, temperature cycling)