Small Neodymium Magnets – N52 Grade for Electronics & Motors丨CORT

Small Neodymium Magnets Product Overview

Introducing our Small Neodymium Magnets in arc shape – high-performance, compact magnetic components for precision applications. Made from premium NdFeB material (neodymium iron boron magnets), these arc-shaped magnets have high magnetic strength in a small size. Standard grade is N52 (customizable to meet your project needs), featuring a nickel coating for durability and tight tolerance control (±0.05mm or customized). These grades are ideal for electronic products, speaker systems, industrial machinery, solenoids, and motors.

Small Neodymium Magnets Core Specifications

- Neodymium magnet grades: Standard N52, customizable to meet your magnetic strength requirements. N52 grade has a strong magnetic pull for compact space operation.

- Shape: Arc-shaped. This unique shape allows for optimized magnetic field distribution, perfect for applications where space is limited and a curved magnetic surface is required, such as motors or precision electronic devices.

- Material: NdFeB Magnet (Neodymium – Iron – Boron). High-performance magnetic material with excellent magnetic energy product, these small magnets can generate a strong magnetic field.

- Coating: Nickel coated. Nickel coating provides corrosion resistance, protects the magnet from environmental factors like moisture and chemicals, and enhances aesthetic and durability.

- Tolerance: ±05mm as standard, customizable tolerance available. This precision ensures seamless integration into your project, whether it’s for high-precision electronic components or industrial assemblies.

- Export Markets: Global. Our magnets meet international quality standards, suitable for use in various regions worldwide.

- Specification Compliance: ROHS, SGS, CE certified. These certifications ensure our magnets are environmentally friendly, safe, and meet strict quality and performance standards.

Small Neodymium Magnets Product Advantages

- Compact but Powerful: These arc-shaped neodymium magnets may be small, but they pack a strong magnetic punch. N52 grade has high magnetic flux density, perfect for applications where space is limited but a strong magnetic force is required, such as miniature electronic devices or small-scale industrial machinery.

- Durable Nickel Coating: Nickel coating not only protects the magnet from corrosion but also enhances wear resistance. This ensures long service life, even in harsh environments or frequent handling, like jewelry magnets or industrial components.

- Tolerance: ±05mm as standard (customizable). Precise for solenoids and motors, where minor deviation can affect performance.

- Customization: From grade and size to coating and tolerance, we have many options. Need a specific magnetic strength for a speaker magnet or a unique size for jewelry application? We can customize to your exact requirements.

- Global Compliance: ROHS, SGS, CE certified. Safe for use in various applications and regions. Gives manufacturers and end users peace of mind that environmental and safety standards are met.

Small Neodymium Magnets Application Scenarios

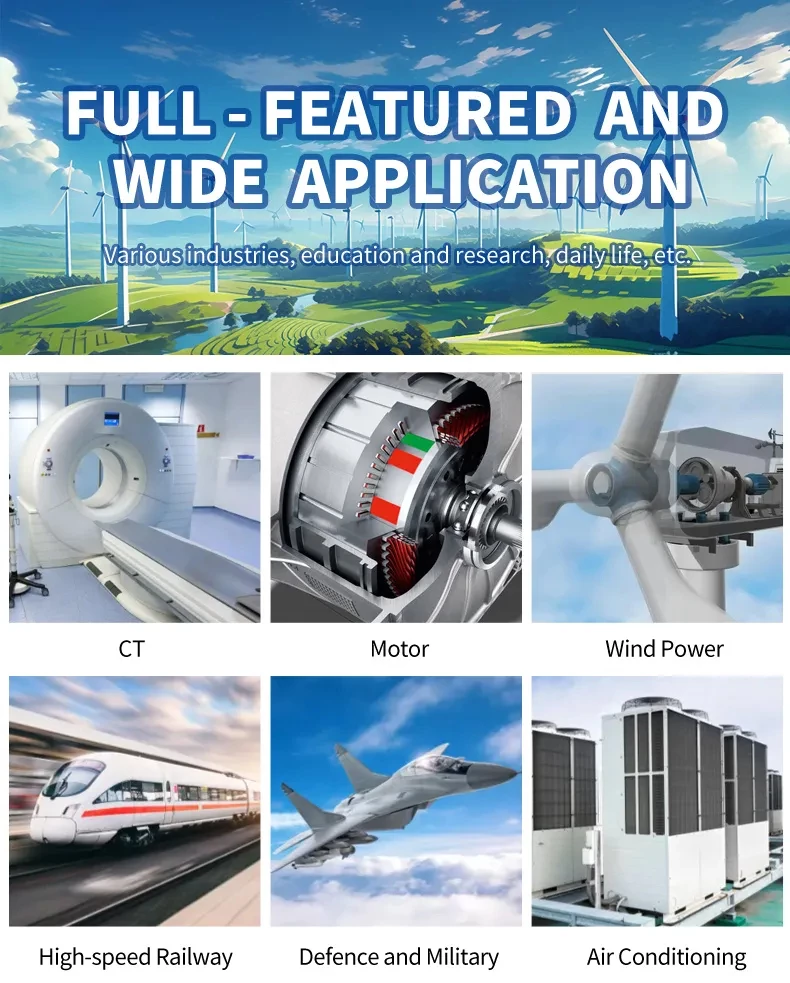

- Electronic Products: In small electronic devices such as smartphones, tablets, and wearable gadgets, these arc-shaped neodymium magnets can be used in components like sensors, actuators or magnetic connectors. Their small size and strong magnetism make them perfect for auto-alignment in wireless charging or precise movement in small motors.

- Speaker Magnet: In speakers, especially small – form – factor ones like those in headphones or portable audio devices, these magnets help to create a stable magnetic field that interacts with the voice coil. This interaction is crucial for good sound. The arc can be optimized to fit the speaker’s design for better sound.

- Industrial Neodymium Magnets: In industrial applications like magnetic holding fixtures, small-scale magnetic separators, or as part of precision machinery. For example, they can hold workpieces in place during machining or separate ferromagnetic particles in small-volume fluid processing.

- Solenoid: In solenoid-based systems, like small valves or actuators, these magnets provide the magnetic force to actuate the solenoid. The arc can be designed to match the solenoid’s geometry for efficient energy conversion and reliable operation.

- Motor Magnet: In motors, especially small motors like those in drones, electric toys, or small appliances, these arc-shaped neodymium magnets play a key role. They create the magnetic field for motor rotation, and their small size allows for smaller, more efficient motors.

Small Neodymium Magnets Customization Services

We know every project is unique. That’s why we offer a full customization service for our Small Neodymium Magnets.If you need custom neodymium magnets, you can contact us and we will provide you with a professional one-stop customized solution

Small Neodymium Magnets Customizable Options

- Grade: While N52 is our standard grade, we can provide other neodymium magnet grades to meet your magnetic strength requirements. Whether you need a lower grade for cost-sensitive applications or a higher grade for extreme performance requirements, we can do that.

- Size and Shape: Our arc-shaped magnets can be customized to your dimensions (inner radius, outer radius, thickness) to fit your design. We can also create non-standard arc shapes or modify the curvature to match your application’s geometry.

- Coating: In addition to the standard nickel coating, we offer zinc, epoxy, or gold plating. These alternative coatings provide different levels of corrosion resistance, aesthetic finishes, or compatibility with specific environments.

- Tolerance: If your project requires a tighter or different tolerance than our standard ±05mm, we can adjust the manufacturing process to meet your tolerance requirements. So the magnets will fit into your assembly perfectly.

Small Neodymium Magnets Customization Process

- Consultation: Reach out to our team via our website, email, or phone. Share your project details, including the desired application, required specifications (grade, size, shape, coating, tolerance), and any other specific needs.

- Design and Quotation: Our experienced engineers will work with you to design a custom solution. We will then provide a detailed quotation that includes the cost, lead time, and any other relevant information.

- Sample Production (Optional): If you need to test the custom magnets before mass production, we can produce a small batch of sample magnets for your evaluation. This allows you to verify that the magnets meet your expectations in terms of performance and fit.

- Mass Production: Once you approve the sample (or if you choose to skip the sample stage), we will proceed with mass production. Our state – of – the – art manufacturing facilities ensure that the magnets are produced to the highest quality standards.

- Delivery: We will ship the custom magnets to your location, ensuring they arrive on time and in perfect condition. We offer global shipping to meet the needs of our international customers.

Frequently Asked Questions—Small Neodymium Magnets

1: Can these small arc - shaped neodymium magnets be used in high - temperature applications?

The maximum operating temperature depends on the grade and coating. For standard N52 grade with nickel coating, the recommended maximum operating temperature is around 80°C. However, we can provide magnets with modified grades or coatings that can withstand higher temperatures (up to 200°C or more) for specific applications. Contact our team to discuss your high-temperature requirements.

2: Are these magnets safe for use in jewelry?

Yes. Our neodymium magnets are nickel – coated, which provides a safe and durable finish. However, as with any small magnet, they should be kept away from young children to prevent ingestion. When used in jewelry, they provide a strong and secure clasp while remaining discreet.

3: How do I determine the right grade of neodymium magnet for my application?

The choice of grade depends on your application’s requirements for magnetic strength, operating temperature, and cost. Our team of experts can help you select the appropriate grade based on your specific needs. Provide us with details about your application, such as the required magnetic force, operating environment, and any space constraints, and we will recommend the best grade for you.

4: Can I order a mix of different sizes and grades in the same batch?

Yes. We support mixed – batch orders, allowing you to order different sizes, grades, and coatings of small arc – shaped neodymium magnets in a single batch. This flexibility is ideal for projects that require a variety of magnetic components.

5: What is the lead time for custom - made magnets?

The lead time for custom-made magnets depends on the complexity of the customization and the order quantity. For standard customizations, the lead time is typically between 2 – 4 weeks. For more complex or large-volume orders, it may take longer. We will provide you with an accurate lead time during the quotation process and keep you updated throughout the production process.

6.What is NdFeB Magnets?

When I ask myself, “What is NdFeB magnets?” I think of neodymium-iron-boron magnets. People also call them neodymium or NdFeB magnets. These magnets combine neodymium, iron, and boron, creating the strongest rare-earth magnets available today. Their unique crystal structure, known as Nd2Fe14B, enables them to generate powerful magnetic fields.