Tiny Neodymium Magnets-Customizable for Diverse丨CORT

Tiny Neodymium Magnets Product Description

Get into our Tiny Neodymium Magnets! These are high-precision, ring-shaped magnets that give you excellent magnetic performance and reliability. Made from top-grade NdFeB material, they come with Ni-Cu-Ni coating (or customized coatings). These small magnets are ideal for spaces where a strong magnetic force and long-lasting durability are essential. Whether used in electronic products, speaker systems, or industrial settings, they consistently deliver excellent results.

Tiny Neodymium Magnets Core Parameters

- Neodymium magnet grades: N45 or customized grades. This ensures the magnets have strong magnetic properties to handle various tasks that require magnetic attraction.

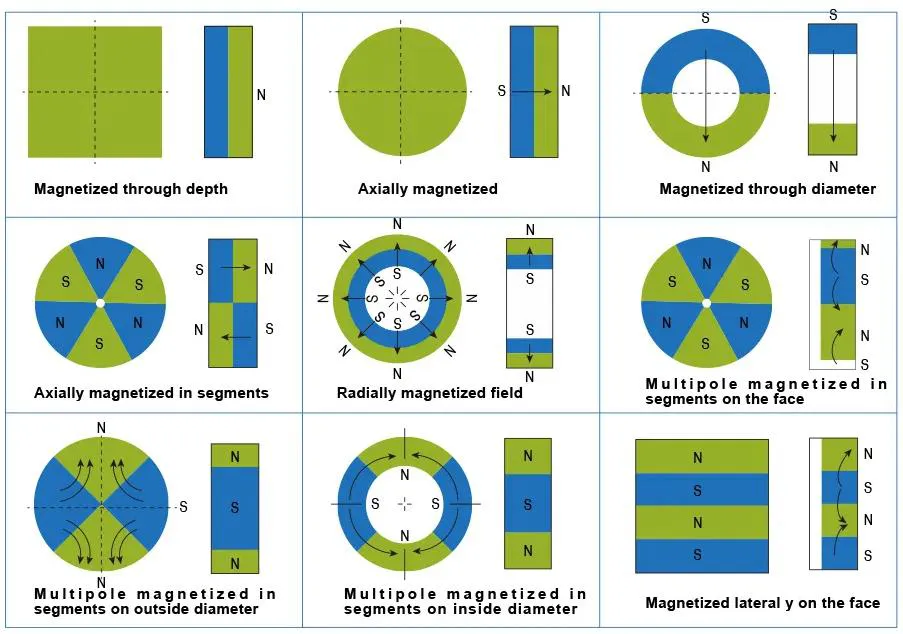

- Shape: Ring-shaped. The ring design offers a unique magnetic field distribution, easy to integrate into applications like solenoids and motors.

- Material: NdFeB Magnet. NdFeB (neodymium iron boron magnets)is a powerful magnetic material that offers a strong magnetic field in a compact form.

- Coating: Standard Ni – Cu – Ni coating, or customized coatings. Ni-Cu-Ni coating provides excellent corrosion resistance and environmental protection for magnets, with customizable options for specific applications.

- Size: Customized. We can customize ring sizes for delicate electronic devices or industrial applications.

- Tolerance: +/-0.05mm or customized. This high precision ensures the magnets fit and function perfectly in various applications, from electronics to industrial projects.

Tiny Neodymium Magnets Product Features

- Strong Magnetism in Small Size: These magnets, especially N45 grade, have a strong magnetic pull. Perfect for precise positioning in electronic products or providing a magnetic field in small speakers.

- Durable Coating Options: Standard Ni – Cu – Ni coating, or other customized coatings, form a protective barrier against corrosion. This enhances the magnet’s lifespan, making it suitable for harsh, humid, and corrosive environments.

- Multi-Purpose: These tiny ring-shaped magnets are multi-purpose. They can act as sensors or actuators in electronics, enhance speaker sound quality, assist with small-scale lifting, be used in jewelry clasps, and improve efficiency in solenoids and motors.

- Customizable: Customizable size, grade, coating, and tolerance.

Tiny Neodymium Magnets Application Scenarios

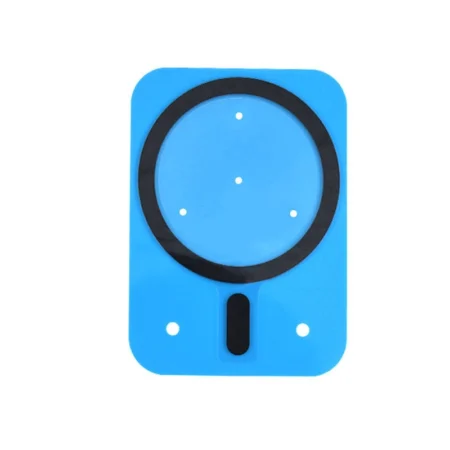

- Ring-shaped neodymium magnets are used in small devices like smartwatches and earbuds for precise magnetic functions. Their small size and strong magnetism make them perfect for these compact, high-precision applications.

- In small speakers, like those in headphones, neodymium ring magnets create a stable magnetic field that interacts with the voice coil, converting electrical signals into clear sound waves.

- Industrial Neodymium Magnets are used in small-scale lifting equipment to pick up tiny metallic parts and in magnetic separators to remove ferromagnetic impurities from materials. This ensures the purity of products in processes like precision manufacturing or small-batch food production.

- Jewelry Magnet: In the jewelry industry, these tiny ring magnets can be used for secure and discreet clasps in delicate jewelry pieces like bracelets or necklaces. They allow for easy opening and closing while providing a strong hold to keep the jewelry securely fastened.

- Solenoid: In solenoid systems, tiny ring magnets create the magnetic field needed to actuate the solenoid in miniature valves or small actuators. Their small size and strong magnetic force ensure efficient operation in these compact systems.

- Motor Magnet: In small motors, such as those in drones or robotic devices, these ring magnets generate the magnetic force needed for rotation. Their high magnetic strength enables efficient energy conversion, making the motors powerful and energy-efficient despite their size.

Tiny Neodymium Magnets Customization Services

We know every project is unique. That’s why we offer a full customization service for our Tiny Neodymium Magnets.If you need custom neodymium magnets, you can contact us and we will provide you with a professional one-stop customized solution

Tiny Neodymium Magnets Customizable Aspects

- Size: We can customize extremely small ring magnets for micro-electronic devices or specifically sized rings for industrial applications to meet your needs. From very small inner and outer diameters to customized thicknesses, we’ve got you covered.

- Grade: N45 is standard, but we can offer other grades of neodymium magnets to meet your project’s specific magnetic strength needs.

- Coating: We offer standard Ni-Cu-Ni coatings and customizable options, including various metal platings and organic coatings. These can provide different levels of corrosion resistance, appearance, and compatibility with other materials.

- Tolerance: We offer standard +/-0.05mm as well as customized tolerance to meet your precision needs for micro-electronic components or general industrial use.

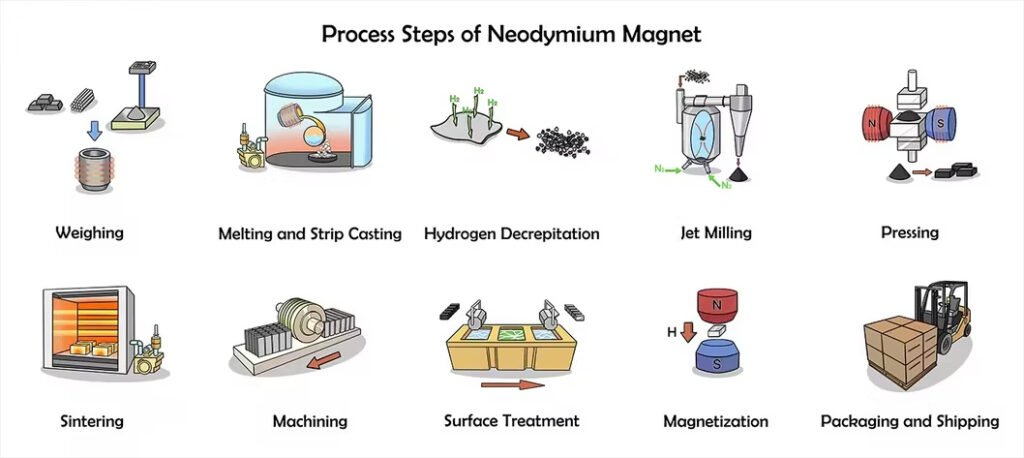

Tiny Neodymium Magnets Customization Process

- Contact: Reach out to us with your specific requirements. Use our online contact form, email, or give us a call. Our sales and engineering team will work with you to get all the details.

- Design and Quote: We will design a custom solution based on your requirements and send you a quote with price, lead time, and all the details.

- Sample (Optional): If you want to test the custom magnets before mass production, we can produce a small batch of samples for your approval. This way, you can verify that the custom magnets meet your expectations.

- Mass Production: Once you approve the sample (or if you choose to skip the sample stage), we will start mass production. Our advanced facilities ensure the magnets are produced to the highest quality.

- Shipping: We will ship the custom magnets to you and ensure they arrive on time and in perfect condition.

Frequently Asked Questions—Tiny Neodymium Magnets

1.What is the max operating temperature of these tiny neodymium magnets?

Max operating temperature depends on the grade and coating. For N45 grade with standard Ni – Cu – Ni coating, it’s around 80°C (176°F). We can provide magnets with modified grades or coatings for higher temperature applications. Just let us know your requirements.

2.Can these tiny ring magnets be used in corrosive environments?

Standard Ni – Cu – Ni coating provides good corrosion resistance. But for highly corrosive environments, we recommend customized coatings like epoxy or other specialized platings. We can discuss the best coating option for your specific corrosive conditions.

3.How does the magnetic strength of these tiny magnets compare to larger ones?

These tiny neodymium magnets, especially with N45 grade, have a high magnetic energy product. Even though they are small, they can generate a relatively strong magnetic field compared to other types of magnets of the same size. In applications where space is limited, they offer a powerful magnetic solution.

4.Are there any safety precautions when handling these tiny magnets?

Yes. They are small and strong, so keep them away from small children to prevent ingestion. Also, they can interfere with electronic devices, credit cards, and pacemakers, so keep them at a safe distance from these items.

When handling, be careful as they can snap together or onto metal surfaces with force and potentially cause injury or chip the magnets.

5.Can I return the magnets if they don’t meet my customized requirements?

We have a customer friendly return policy. If the custom made magnets don’t meet your requirements because of an error on our part (e.g. wrong size, grade, coating or tolerance), we will accept returns and provide a replacement or refund. Please discuss your requirements thoroughly before production to avoid any issues.

6.What is NdFeB Magnets?

When I ask myself, “What is NdFeB magnets?” I think of neodymium-iron-boron magnets. People also call them neodymium or NdFeB magnets. These magnets combine neodymium, iron, and boron, creating the strongest rare-earth magnets available today. Their unique crystal structure, known as Nd2Fe14B, enables them to generate powerful magnetic fields.