Circular AlNiCo Magnets

Circular or cylindrical, with magnetic poles on the flat surfaces (axial magnetization) or circumference (radial magnetization). Made from aluminum-nickel-cobalt alloys, these magnets have excellent thermal stability (up to 525°C) and corrosion resistance, and maintain magnetic performance in extreme environments. Sizes range from 3mm to 200mm in diameter and 2mm to 100mm in thickness.

- Industrial Furnaces:Temperature-resistant sensors in steel mills and foundries.

- Aviation Engines:Magnetic components in jet engine ignition systems.

- Medical Equipment:Permanent magnets in radiation therapy machines.

Annular AlNiCo Magnets

Hollow ring-shaped with radial or axial magnetization, designed to create uniform magnetic fields around the central bore. These magnets are great for applications that require stable flux distribution and mechanical integration with shafts or cables. They have high coercivity and retain magnetism after being exposed to strong external fields.

- Scientific Instruments:Mass spectrometers and particle accelerators.

- Automotive Sensors:Crankshaft position sensors in high-temperature engine compartments.

- Renewable Energy:Generator rotors in geothermal power plants.

Square AlNiCo Magnets

Rectangular or cubic, with magnetic poles on opposite flat surfaces. Strong mechanical strength and stable magnetic fields make them ideal for assemblies that require stacked configurations to increase magnetic force. They resist demagnetization in harsh mechanical environments.

- Heavy Machinery:Magnetic chucks in metalworking lathes and milling machines.

- Defense Systems:Magnetic clutches in tank transmissions.

- High-Temperature Motors:Stator components in industrial ovens and kilns.

Special-Shape AlNiCo Magnets

Non-standard shapes (e.g., arc-shaped, T-shaped, perforated, or multi-angle profiles) are machined to meet specific design requirements. Precision grinding or EDM (electrical discharge machining) ensures tight tolerances (±0.01mm) for complex geometries to meet niche magnetic field needs.

- Aerospace:Curved magnets for aircraft compass systems.

- Optical Equipment:Magnetic mounts in high-precision laser alignment systems.

- Marine Technology:Corrosion-resistant magnets in subsea exploration vehicles.

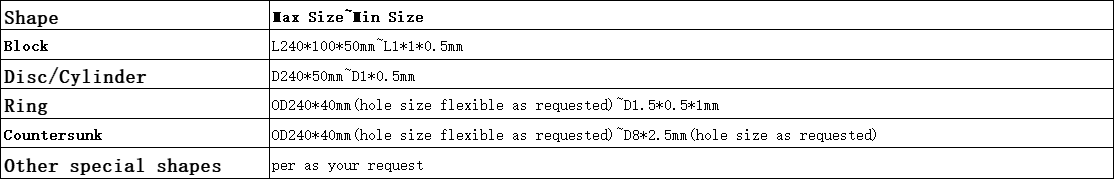

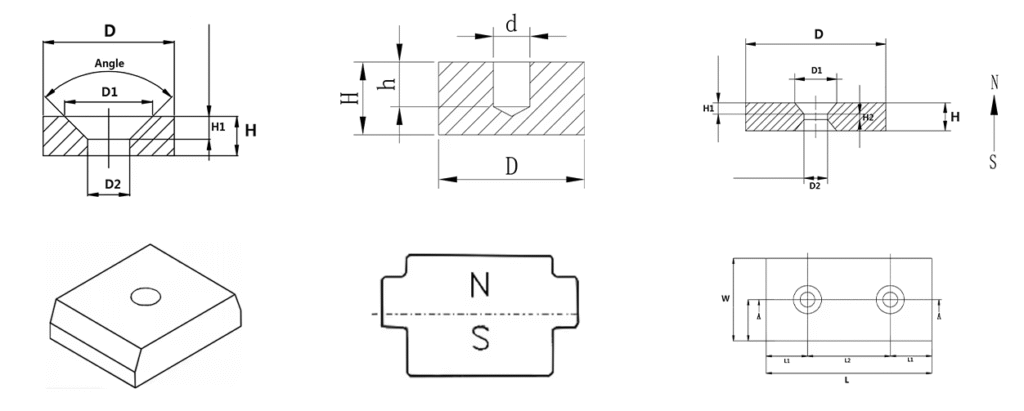

1.Shape and size

Standard geometric shape

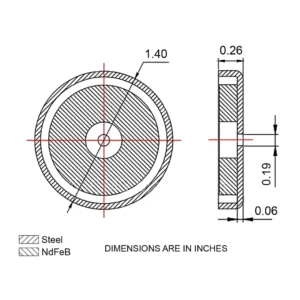

- Circular/ring-shaped: Diameter φ3mm to φ300mm, inner diameter of the ring φ10mm to φ200mm, supports axial/radial magnetization.

Annular magnetic steel for automotive generators (inner diameter φ50mm, outer diameter φ80mm, radially magnetized). - Square/rectangular: Side length 5mm to 200mm, thickness 2mm to 150mm, can be stacked to form a magnetic circuit system.

Rectangular magnetic blocks for industrial lifting equipment (100mm×50mm×30mm, with bipolar magnetization on the surface).

Irregular shapes and precision processing

- Complex shapes: tile-shaped, fan-shaped, stepped or threaded hole structure, with an accuracy of ±0.01mm (CNC grinding machine processing required).

Arc-shaped magnetic steel for Marine compasses (with a radius of curvature R80mm and a thickness of 8mm, used for geomagnetic field compensation). - Miniaturized customization: Miniature disc magnets with a diameter of ≤2mm, used in micro-electromechanical system (MEMS) sensors.

2.Dimensional accuracy

Customizable parameters such as diameter/side length, thickness, aperture, and curvature are available, with an accuracy of ±0.01mm (requiring precise processing techniques).

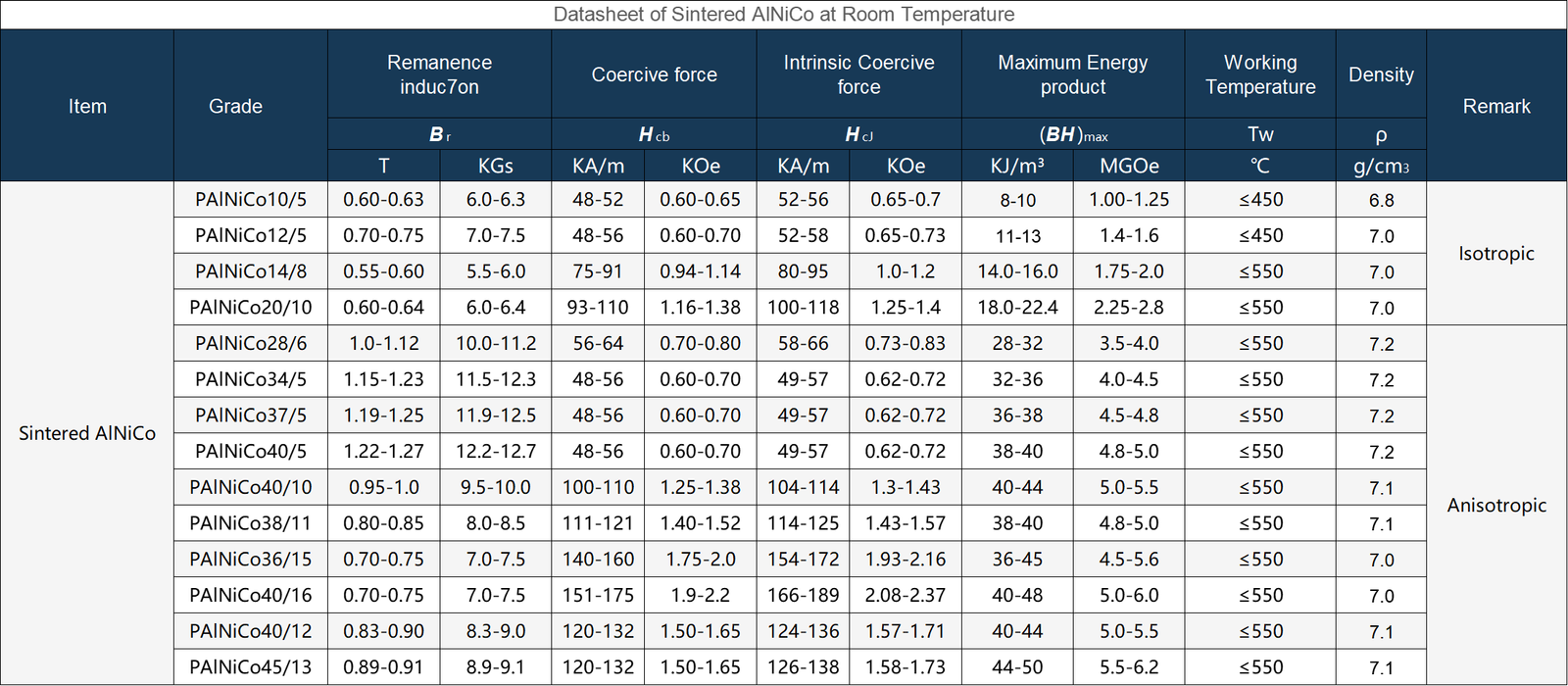

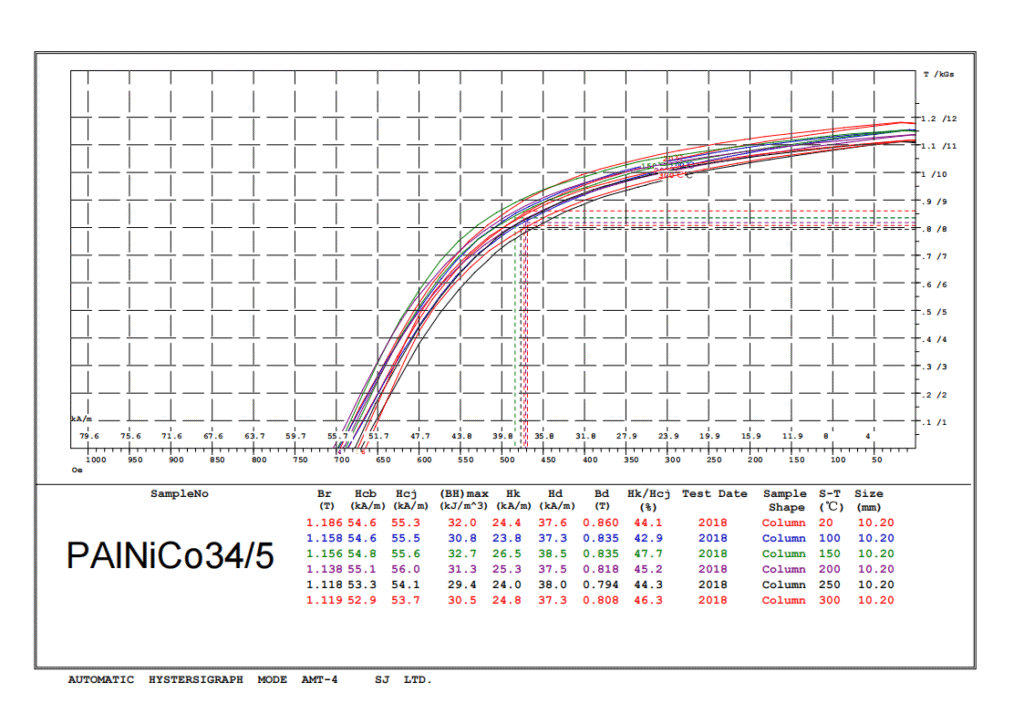

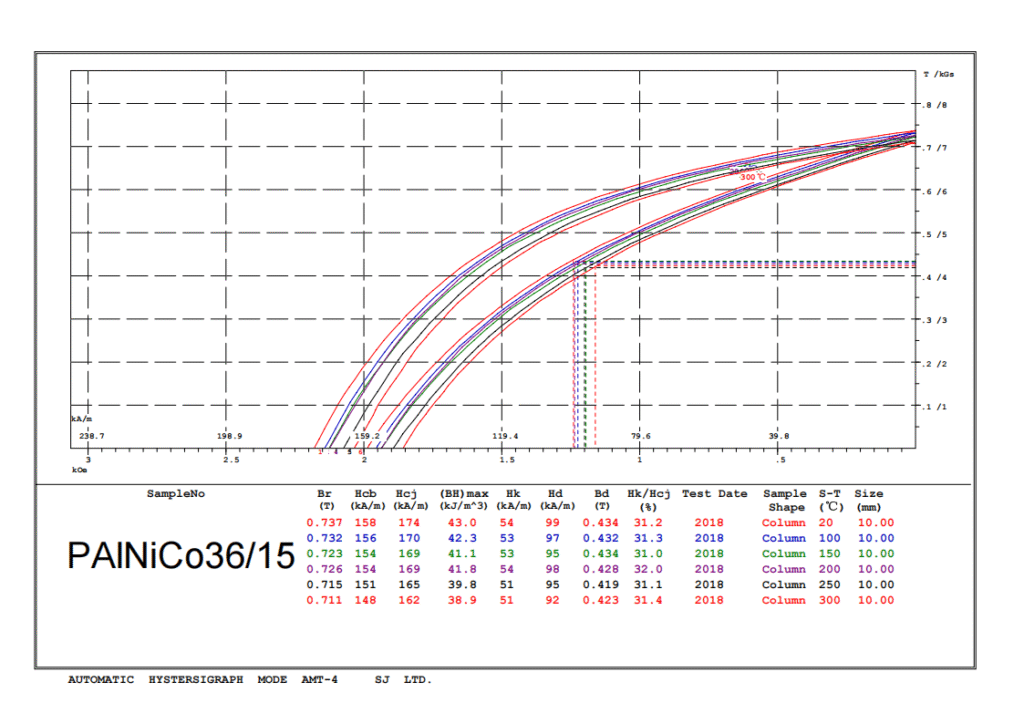

3. Material grade

- AlNiCo 5: Magnetic energy product 11-14 MGOe, temperature resistance up to 525℃, suitable for medium magnetic field intensity requirements.

- AlNiCo 8: Magnetic energy product 13-16 MGOe, higher coercive force (≥7.5 kOe), strong anti-demagnetization ability, suitable for complex magnetic field environments.

- AlNiCo 9: Magnetic energy product 14-18 MGOe, temperature resistance up to 600℃, suitable for extremely high-temperature scenarios.

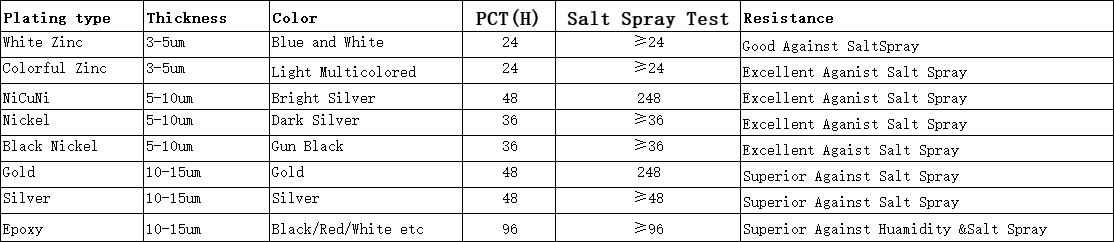

4. Coating process

Coating process: nickel (Ni) plating, copper (Cu) plating, silver (Ag) plating, thickness 10μm to 30μm, salt spray test.

Scene: Magnets for Marine engineering (nickel-plated + epoxy resin encapsulated, resistant to seawater corrosion).

Thermal spraying treatment: Spray ceramic coating (such as Al₂O₃), wear-resistant, and with insulation resistance > 100MΩ.

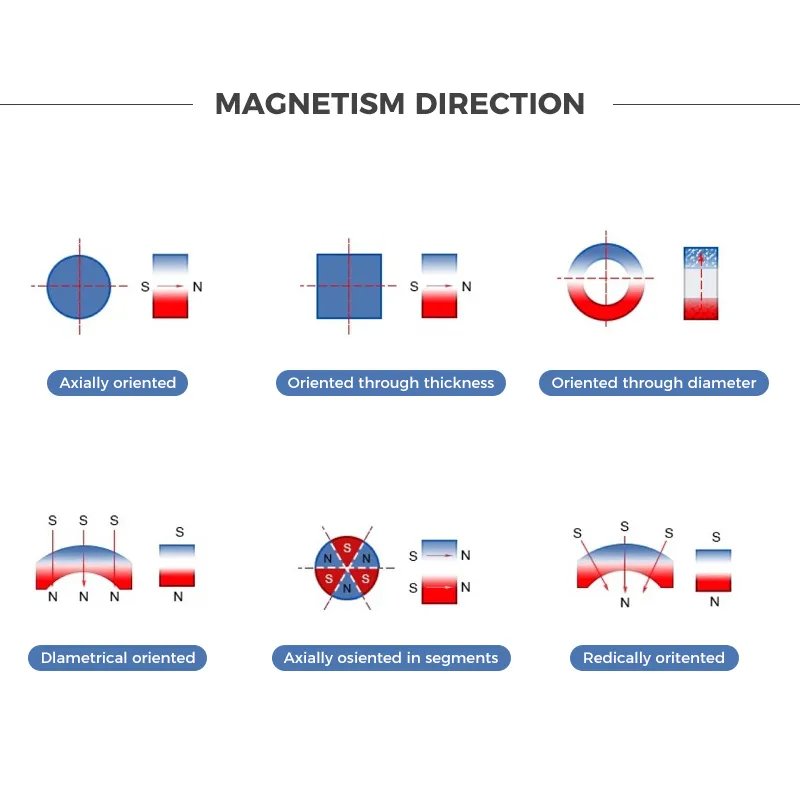

5. Magnetization direction and magnetic field distribution

- Axial magnetization: The magnetic field lines are perpendicular to the plane (for example, the upper and lower surfaces of a circular magnet are the magnetic poles).

- Radial magnetization: The magnetic field lines are along the radius direction (for example, the inner and outer diameters of a ring-shaped magnet are the magnetic poles).

- Multi-pole magnetization: Multiple N/S poles are distributed on the surface of the magnet (such as sine wave magnetization of sector magnets used in motors).

- Magnetization in any direction: According to design requirements, customize the magnetization Angle in non-standard directions.

6. Customized magnetic properties and tolerances

Magnetic energy product (BHmax): The range of magnetic force intensity can be specified (such as ≥35MGOe).

Tolerance control

Dimensional tolerance: such as diameter ±0.05mm, thickness ±0.02mm.

Magnetic performance tolerance: such as the control of the fluctuation range of residual magnetism (Br) and coercive force (Hcb).

Order Now | Get a Bulk Quote

Frequently Asked Questions—alnico magnets

How do Alnico magnets perform in fluctuating temperature conditions?

Alnico magnets exhibit minimal magnetic decay during temperature cycles, ensuring consistent performance in environments with extreme temperature changes, reducing the need for frequent replacements.

Can I get customized Alnico magnets?

Yes, we offer full customization for shape (bar, ring, arc), size, magnetization direction, and surface finish. Whether for magnetic separators or aerospace components, our team can meet specific design requirements.

What quality certifications do your Alnico magnets have?

Our Alnico magnets comply with ISO 9001 quality management standards, RoHS environmental regulations, and REACH requirements. Each batch undergoes 10 strict tests, ensuring a defect rate below 0.05%.

What is the minimum order quantity (MOQ) for Alnico magnets?

The MOQ for standard Alnico magnets is 100 pieces. For customized products, the MOQ may vary based on complexity, but we can accommodate smaller trial orders for new projects.

How long does it take to deliver custom Alnico magnet orders?

Are your Alnico magnets cost-effective for large projects?

Yes, despite high-performance features, our Alnico magnets offer competitive pricing. Bulk orders can enjoy up to 18% discount, helping you optimize costs without sacrificing quality.