Circular Ferrite Magnets

Flat, round, or cylindrical in shape with magnetic poles on the top and bottom (axial magnetization). Stable magnetic performance and low cost. 3 mm~200 mm diameter, 1 mm~50 mm thick. For moderate magnetic force applications.

- Consumer Electronics:Speaker magnets (e.g., multimedia speakers), microphone pickup components, electronic clock stepper motors.

- Household Items:Refrigerator magnets, magnetic hooks, children's educational puzzle tiles.

- Small Machinery:Toy motors, office equipment (e.g., shredder clutches), vending machine sensors.

Annular Ferrite Magnets

Hollow ring with magnetic poles on inner/outer diameter (radial magnetization) or side surfaces (axial magnetization). Used to guide or shield magnetic fields, often combined with coils to form transformers or inductors. High permeability and low loss.

- Power Equipment:Power transformer cores, choke coils, high-frequency inductors.

- Telecommunications:EMI suppression rings (e.g., computer data cable ferrite cores), RF isolator components.

- Automotive Electronics:Ignition coil cores, ABS sensor rings, car charger transformers.

Square Ferrite Magnets

Cubic or rectangular with magnetic poles perpendicular to opposite planes. Rigid structure and uniform magnetic flux allow stacking to form magnetic circuits. For applications that require fixed magnetic directions or mechanical support.

- Industrial Automation:Machine tool magnetic worktables, conveyor metal detection sensors, textile machinery tension control blocks.

- Home Appliances:Microwave oven magnetron components, induction cooker coil cores, air conditioner compressor solenoids.

- Education & Research:Physics experiment magnetic demonstration blocks, maglev system base components.

Special-Shape Ferrite Magnets

Processed into non-regular shapes (e.g., arc, trapezoidal, perforated/slotted) to meet special spatial or magnetic field distribution requirements (e.g., curved magnetic paths, multi-pole magnetization).

- Motor Manufacturing:Small DC motor arc-shaped magnets (e.g., power tool motors), servo motor stator segments.

- Medical Devices:MRI gradient field components, magnetic therapy patches for joint pain.

- Specialized Equipment:Magnetic lock tongue blocks, smart water meter flow sensors, fitness equipment resistance control magnets.

Support customization options—ferrite magnets

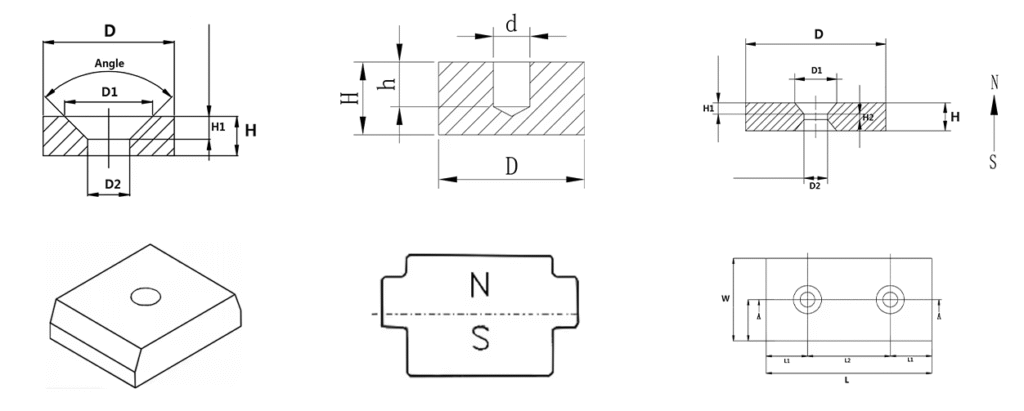

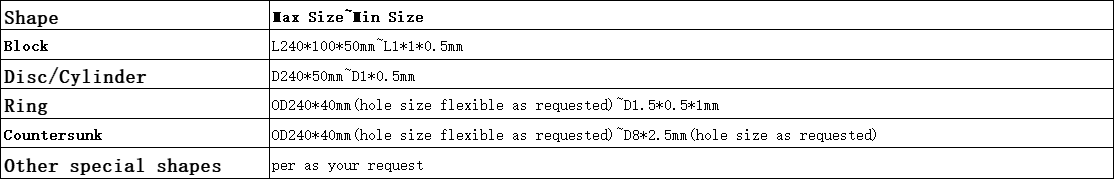

1.Shape and size

Standard shapes: round, square, ring, strip, horseshoe-shaped, etc.

Irregular shapes: Processed into non-regular shapes such as fan-shaped, trapezoidal, concave, perforated/slotted, stepped shapes according to the drawings.

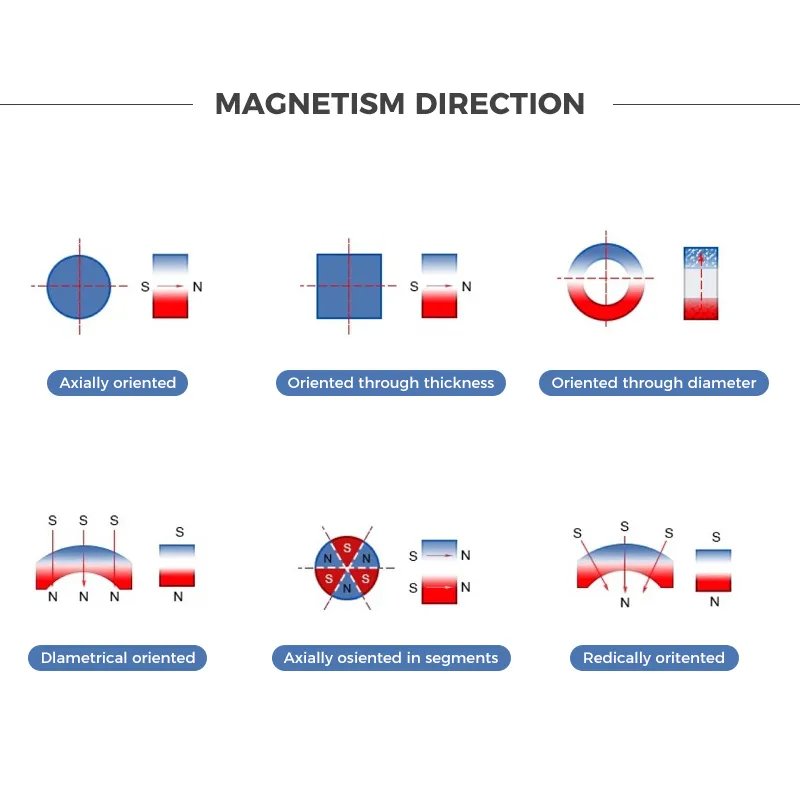

2.Dimensional accuracy

Customizable parameters: diameter/side length, thickness, aperture, curvature. ±0.01mm (require precise processing).

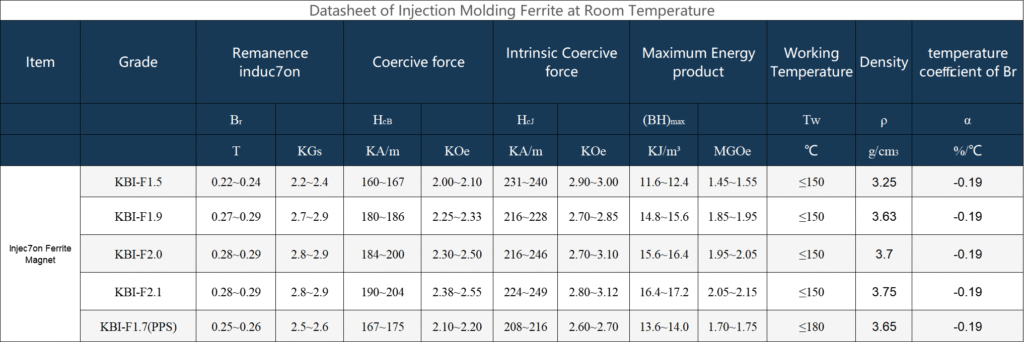

3. Material grade

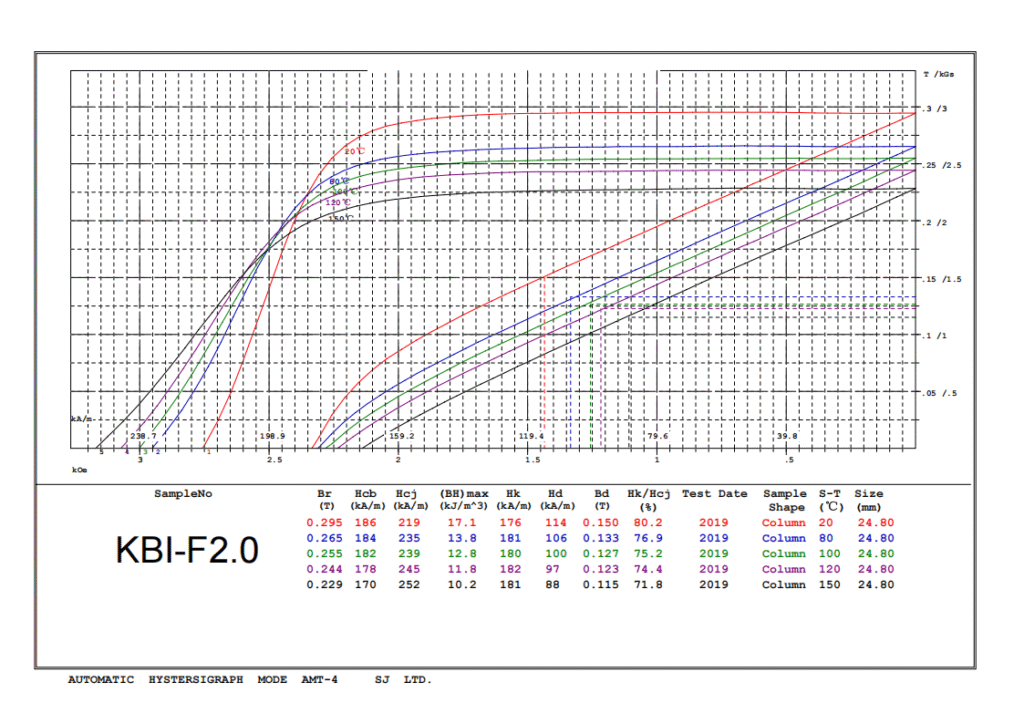

- Material grades: Ferrite materials come in various grades, such as Y25, Y30, Y35, etc. Different grades have differences in magnetic performance parameters such as coercive force, residual magnetism, intrinsic coercive force and maximum magnetic energy product. For example, the residual magnetism of ferrite of Y30 grade is 380-400mT, and the coercive force is 135-170kA/m. The residual magnetism of the Y35 grade can reach 430-450 mT, and the coercive force is 215-239 Ka /m. Based on specific application scenarios, for instance, for speakers with high magnetic force requirements, high residual magnetism grades can be selected; for transformers with high stability requirements, high coercive force grades can be chosen.

- Operating temperature: The operating temperature range of conventional ferrite is from -40 ℃ to + 200℃. However, in special application scenarios, such as high-temperature industrial equipment and the periphery of automotive engines, ferrite that can withstand high or low temperatures can be customized. For instance, to adapt to the high-temperature environment of around 150℃ in the car engine compartment, ferrite materials with a higher Curie temperature and more stable high-temperature magnetic properties can be selected.

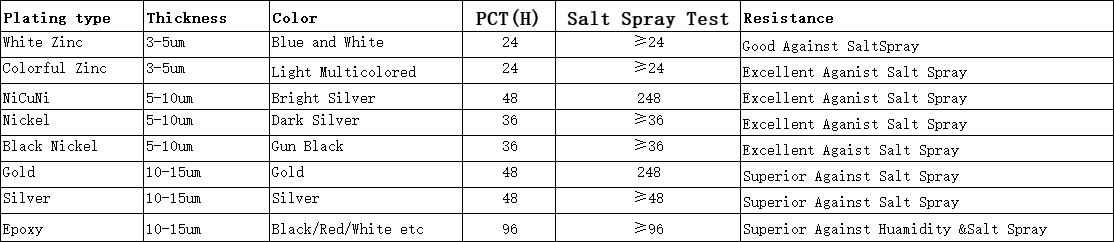

4. Coating process

Rust prevention treatment: Although ferrite is not prone to corrosion, in damp or special environments, surface treatments such as galvanizing and nickel plating can be carried out to enhance its rust prevention ability. For magnetic devices used outdoors, nickel-plated ferrite can effectively resist rain erosion.

Insulation treatment: To meet the electrical insulation requirements in electronic devices, treatments such as coating with insulating varnish and wrapping with insulating materials can be carried out. For instance, in transformers, the ferrite after insulation treatment can prevent the magnetic core from short-circuiting with other components, ensuring the safe operation of the equipment.

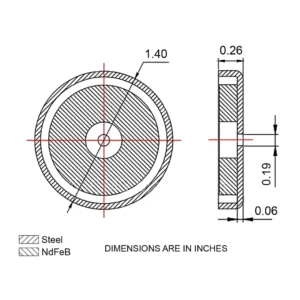

5. Magnetization direction and magnetic field distribution

- Axial magnetization: The magnetic field lines are perpendicular to the plane (for example, the upper and lower surfaces of a circular magnet are the magnetic poles).

- Radial magnetization: The magnetic field lines are along the radius direction (for example, the inner and outer diameters of a ring-shaped magnet are the magnetic poles).

- Multi-pole magnetization: Multiple N/S poles are distributed on the surface of the magnet (such as sine wave magnetization of sector magnets used in motors).

- Magnetization in any direction: According to design requirements, customize the magnetization Angle in non-standard directions.

6. Customized magnetic properties and tolerances

Magnetic energy product (BHmax) : The range of magnetic force intensity can be specified (such as ≥35MGOe).

Tolerance control

Dimensional tolerance: such as diameter ±0.05mm, thickness ±0.02mm.

Magnetic performance tolerance: such as the control of the fluctuation range of residual magnetism (Br) and coercive force (Hcb).

Magnet parameter comparison table

Order Now | Get a Bulk Quote

Frequently Asked Questions—ferrite magnets

How do ferrite magnets compare in cost to rare - earth magnets?

Ferrite magnets offer up to 30% cost savings compared to rare – earth magnets. They are an economical choice for applications where high – intensity magnetic fields aren’t required, such as consumer electronics and small motors.

Are your ferrite magnets resistant to corrosion?

Yes, due to their ceramic composition, ferrite magnets have natural oxidation resistance. Minimal coating is needed, making them suitable for outdoor and humid environments with reduced maintenance requirements.

What customization options are available for ferrite magnets?

We offer a wide range of customization, including various shapes (disc, ring, arc), sizes, and magnetic orientations. The dimensional tolerance can be controlled within ±0.05mm to meet specific design needs.

What certifications do your ferrite magnets have?

Our ferrite magnets are 100% lead – free and compliant with RoHS and REACH regulations. Additionally, we hold ISO 9001 quality management system certification, ensuring product quality and reliability.

What is the minimum order quantity (MOQ) for ferrite magnets?

The MOQ for standard ferrite magnets is 100 pieces. For customized products, the MOQ may vary based on complexity, but we are flexible and can negotiate for larger projects.

How long does it take to deliver custom ferrite magnet orders?

For custom orders, the lead time can be as short as 7 days, thanks to our optimized supply chain and automated production lines. Standard products are usually shipped within 3 working days.

How do you ensure the quality of ferrite magnets?

Each batch of ferrite magnets undergoes 8 strict tests, covering magnetic flux, coercivity, dimensional accuracy, and more. This comprehensive quality control process keeps the defect rate below 0.05%.

Can you provide technical support for magnetic design?

Our team of engineers, with over 10 years of experience in magnetic materials, offers free magnetic field simulation services. We can assist you in optimizing ferrite magnet integration for the best performance.