Circular NdFeB Magnets

Circular (flat disc or cylinder), magnetic poles on top and bottom (axial magnetization) or circumference (radial magnetization). High energy products, 1mm to 300mm in diameter and 0.2mm to 100mm in thickness, ±0.01mm.

- Electronic Devices:Speaker magnets (e.g., headphone units), smartphone vibration motors, sensor cores.

- Industrial Machinery:Small motor rotors, magnetic suction cups, positioning elements in automated equipment.

- Consumer Products:Magnetic phone holders, children's educational magnetic toys (magnetic balls), smart home magnetic switches.

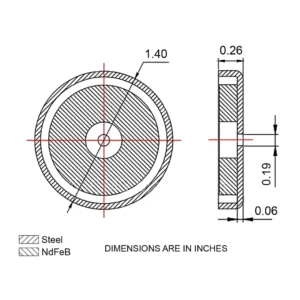

Annular NdFeB Magnets

Hollow ring shape, magnetic poles on inner/outer diameter (radial magnetization) or side surface (axial magnetization). Magnetic field is circular, can integrate wires or shafts through the center hole for magnetoelectric coordination or mechanical connection, suitable for precision applications that require spatial compatibility.

- New Energy:EV motor stator/rotor magnetic rings, wind turbine permanent magnets.

- Communication Equipment:RF component anti - interference magnetic rings, wireless charging coils (e.g., MagSafe annular magnetic arrays).

- Medical Instruments:MRI gradient magnetic field components, dental implant positioning rings.

Square NdFeB Magnets

Cubic or rectangular, magnetic poles are perpendicular to opposite planes. Stable structure and concentrated magnetic flux can form a complex magnetic circuit by splicing. Multi-pole magnetization for high-strength adsorption or fixing.

- Lifting Machinery:Industrial magnetic lifting tools, metal scrap sorting equipment.

- Mechanical Equipment:CNC machine tool fixtures, magnetic guide rails in automated production lines.

- Household Applications:Heavy - duty refrigerator magnets, cabinet magnetic closers, educational physics experiment blocks.

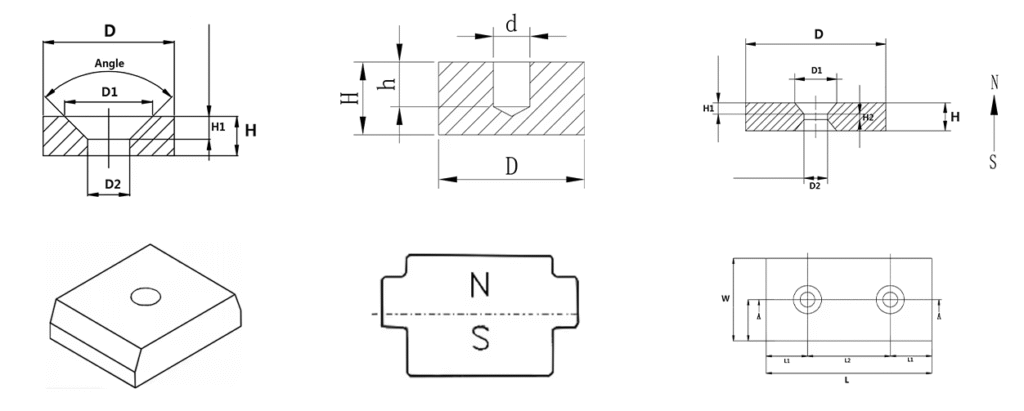

Special - Shape NdFeB Magnets

Non-regular shape (e.g., trapezoid, arc, perforated/slotted, multi-stepped composite) to meet specific requirements. Precision wire cutting and 5-axis machining, ±0.01mm accuracy for complex applications where standard shapes can’t meet.

- Aerospace:Satellite attitude control magnetorquers, micro magnetic components for missile guidance systems.

- High - End Electronics:Folding phone hinge magnetic structures, drone gimbal anti - vibration rings.

- Specialty Motors:Robot joint servo motor special - shape magnets, high - frequency motor multi - pole magnetized rotors.

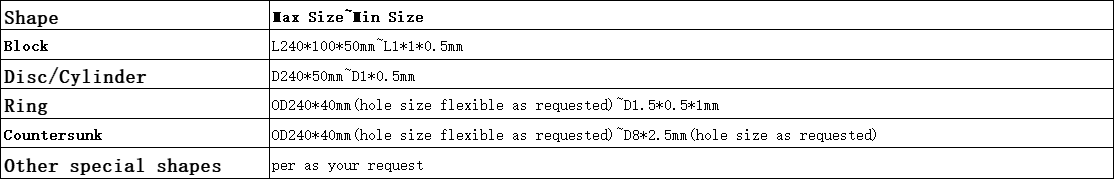

Support customization options—ndfeb magnets

1.Shape and size

Standard shapes: round, square, ring, strip, horseshoe-shaped, etc.

Irregular shapes: Processed into non-regular shapes such as fan-shaped, trapezoidal, concave, perforated/slotted, stepped shapes according to drawings.

2.Dimensional accuracy

Customizable parameters: diameter/length, thickness, aperture, curvature, ±0.01mm (requires precise processing).

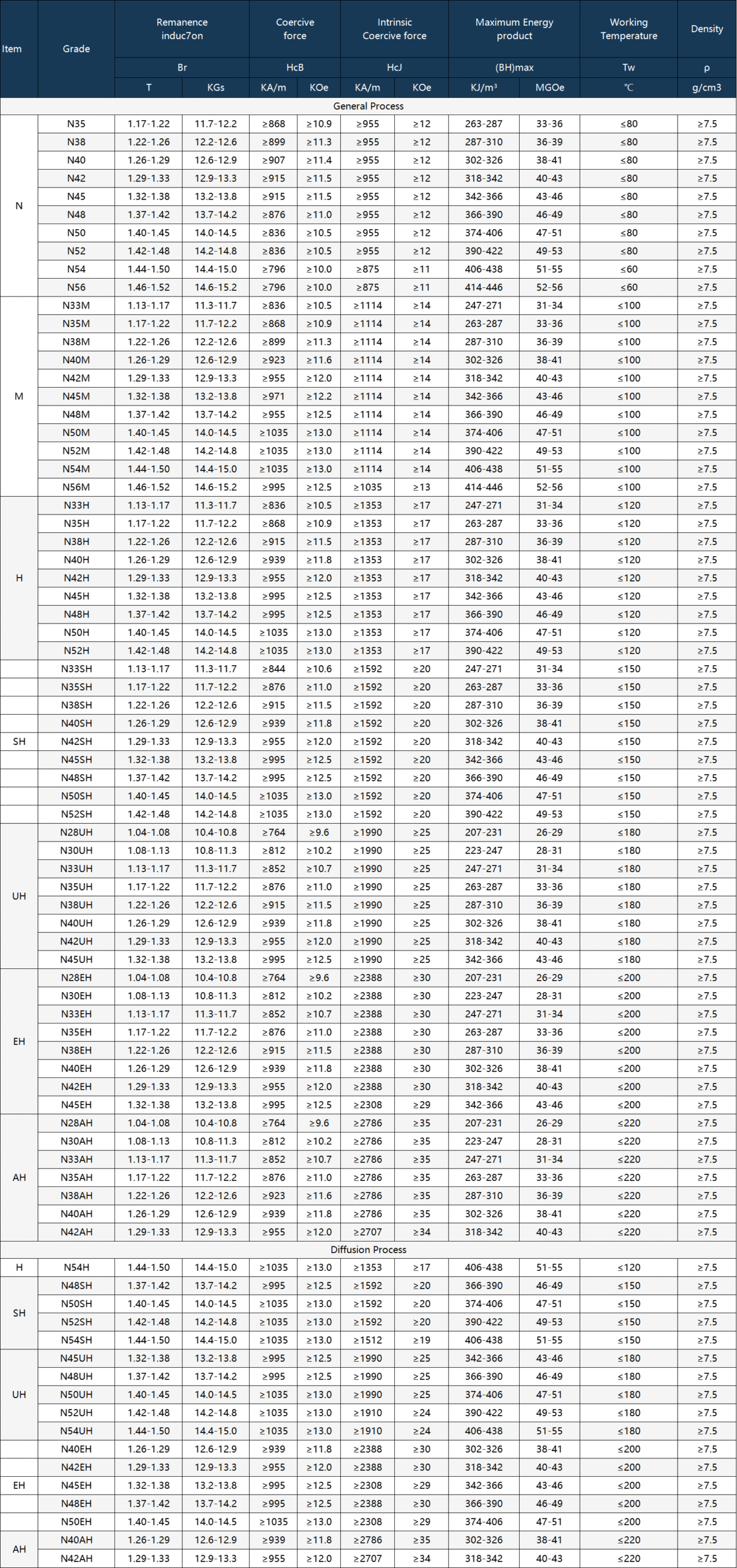

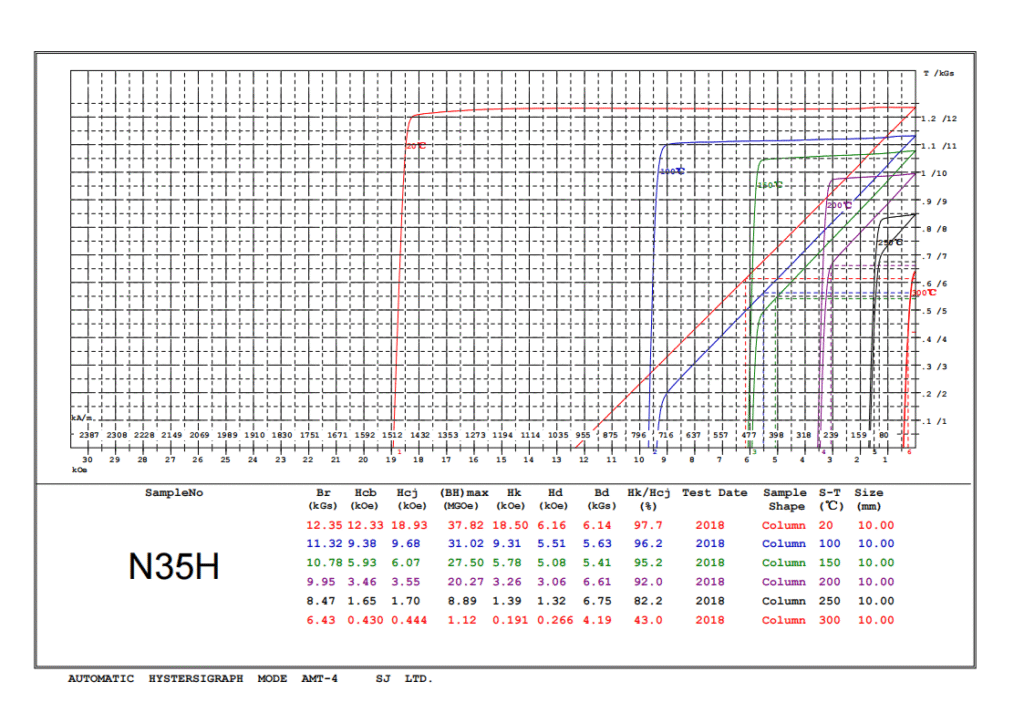

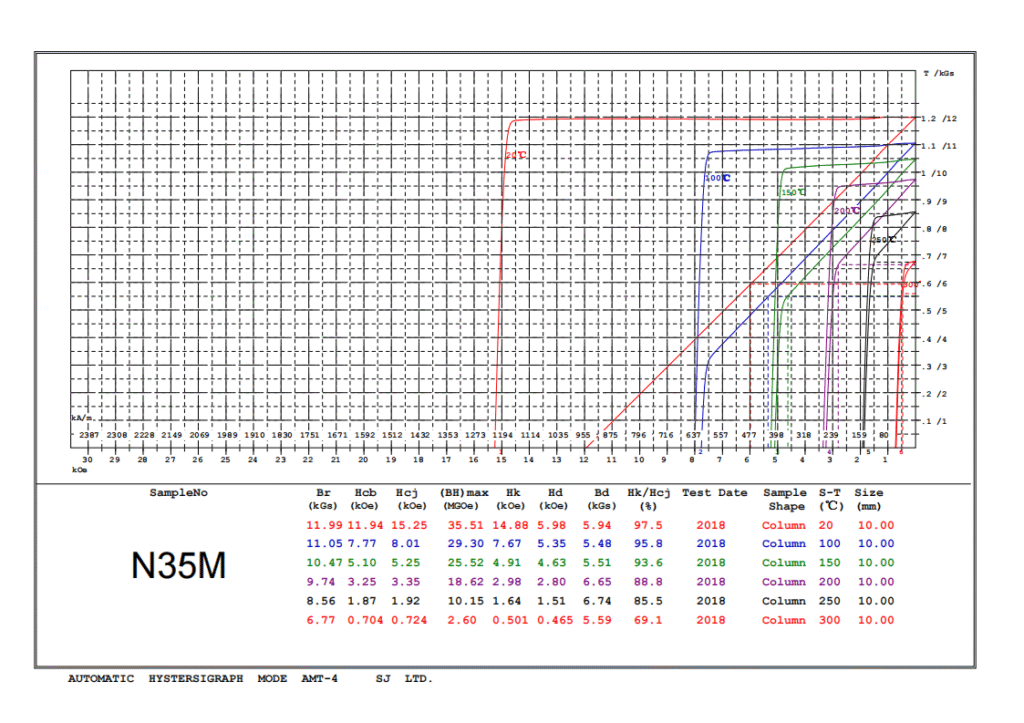

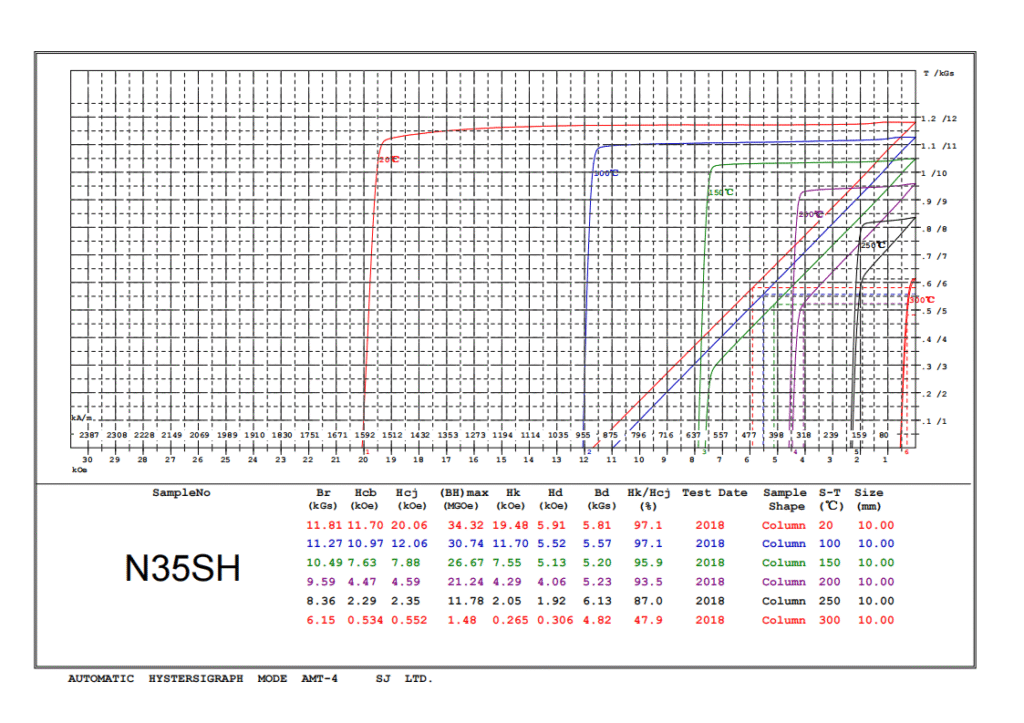

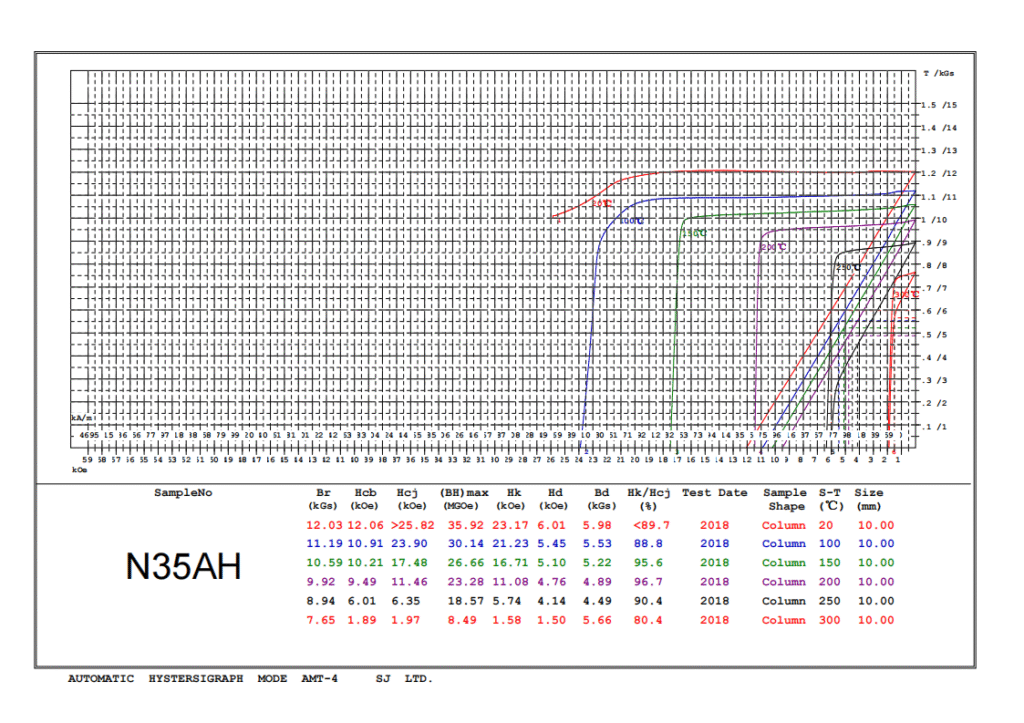

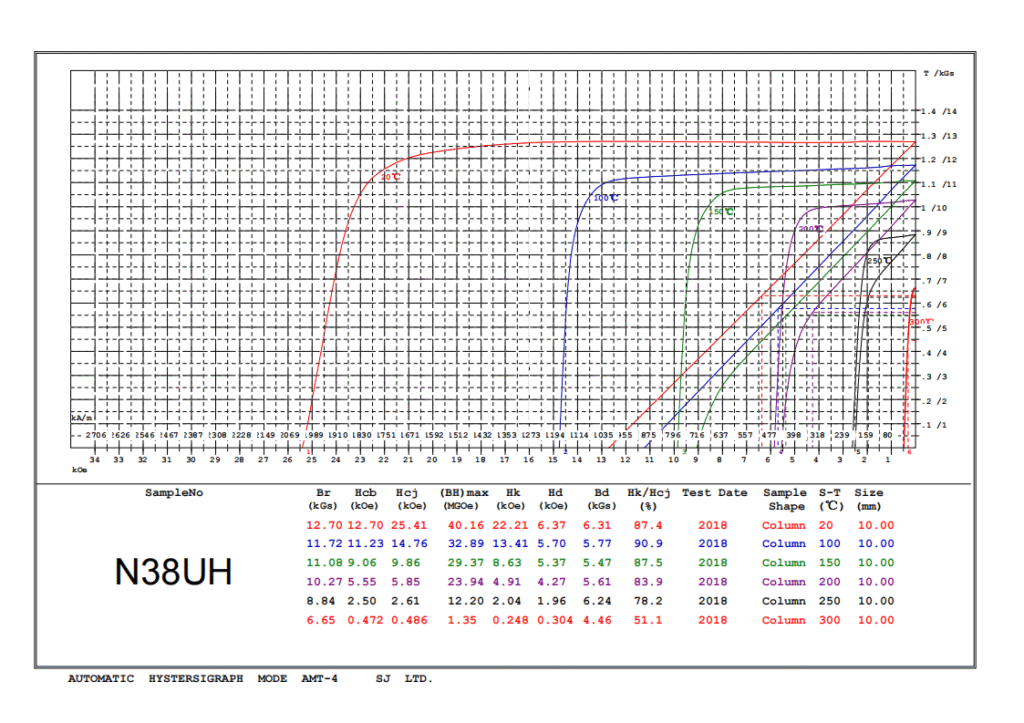

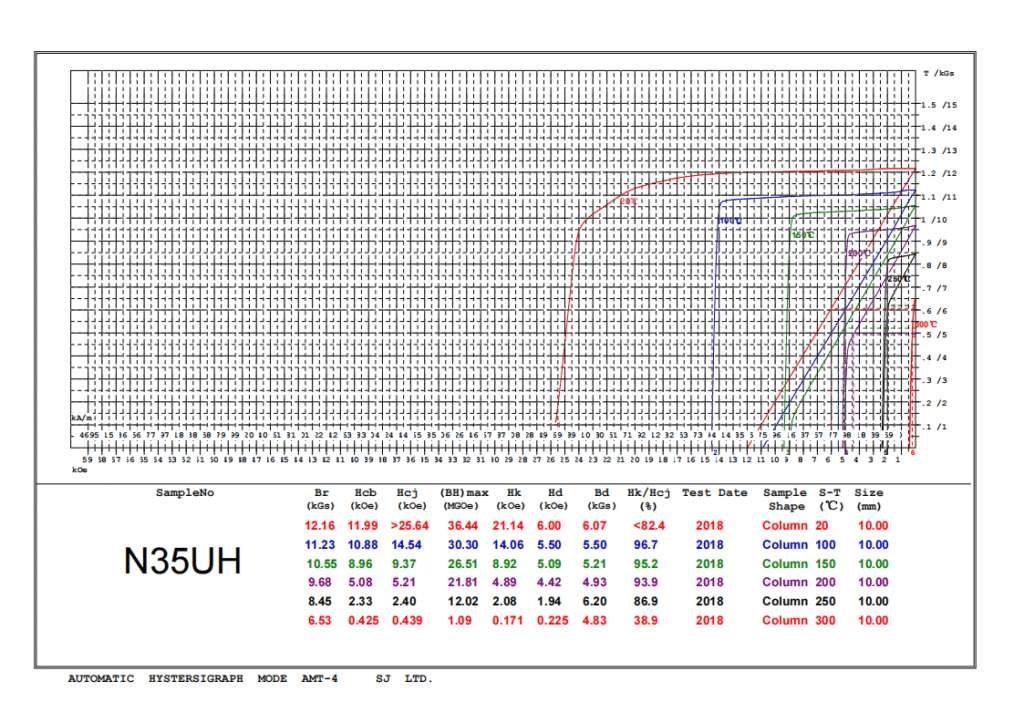

3. Material grade

- Conventional grades: N35-N52 (N stands for Neodymium iron boron. The higher the number, the higher the magnetic energy product and the stronger the magnetic force).

- Special environment grade:

High-temperature resistance: such as N35H/N42SH (H stands for 120℃ resistance, SH for 150℃ resistance, and the maximum can reach 220℃).

High coercive force: such as N38UH (strong anti-demagnetization ability, suitable for environments with strong magnetic field interference).

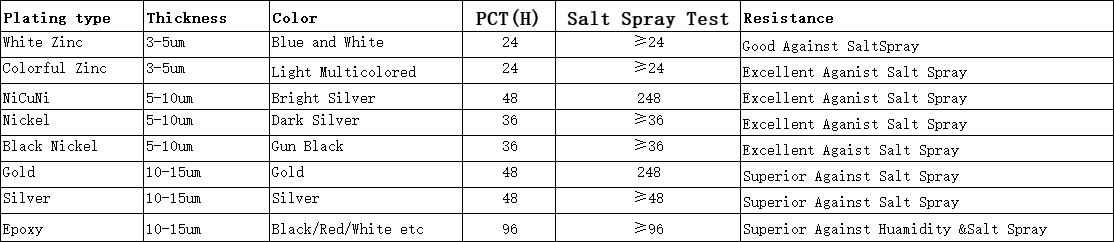

4. Coating process

Coating and surface treatment

Rust and corrosion prevention: galvanizing (Zn), nickel plating (Ni), gold plating (Au), Epoxy plating (Epoxy), etc.

Insulation or aesthetics: Spray rubber, epoxy resin, colored coating, etc.

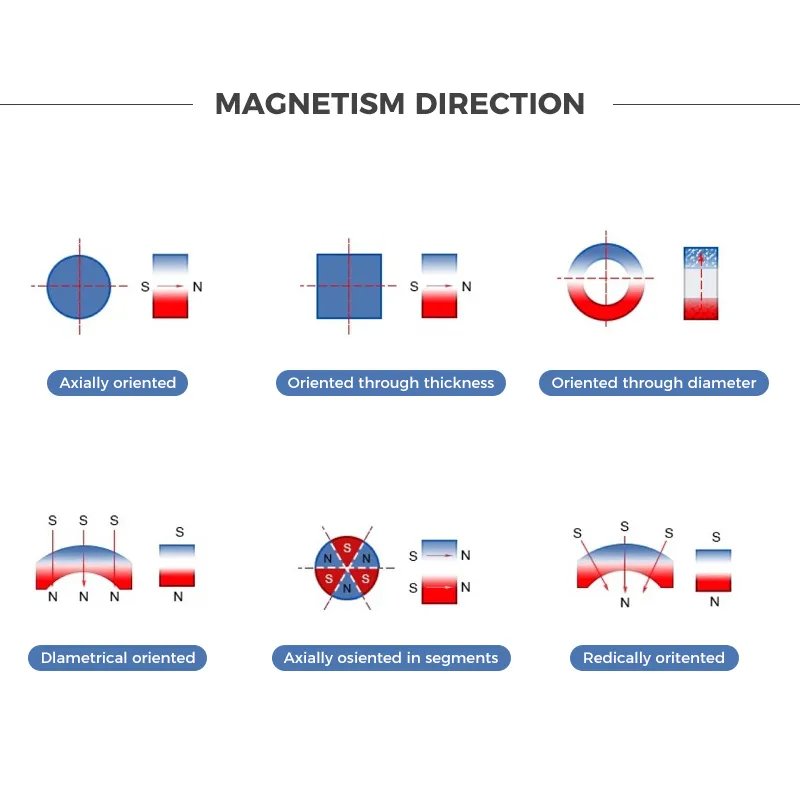

5. Magnetization direction and magnetic field distribution

- Axial magnetization: The magnetic field lines are perpendicular to the plane (for example, the upper and lower surfaces of a circular magnet are the magnetic poles).

- Radial magnetization: The magnetic field lines are along the radius direction (for example, the inner and outer diameters of a ring-shaped magnet are the magnetic poles).

- Multi-pole magnetization: Multiple N/S poles are distributed on the surface of the magnet (such as sine wave magnetization of sector magnets used in motors).

- Magnetization in any direction: According to design requirements, customize the magnetization Angle in non-standard directions.

6. Customized magnetic properties and tolerances

Magnetic energy product (BHmax) : The range of magnetic force intensity can be specified (such as ≥35MGOe).

Tolerance control

Dimensional tolerance: such as diameter ±0.05mm, thickness ±0.02mm.

Magnetic performance tolerance: such as the control of the fluctuation range of residual magnetism (Br) and coercive force (Hcb).

Magnet parameter comparison table

Order Now | Get a Bulk Quote

Frequently Asked Questions—ndfeb magnets

Can I get custom-shaped neodymium magnets?

Yes, we offer full customization for shape, size, and magnetic orientation. Whether you need arc-shaped magnets for motors or complex geometries for medical devices, our engineers can provide tailored solutions.

What certifications do your neodymium magnets have?

Our products are certified with ISO 9001, IATF 16949, RoHS 2.0, and REACH compliance. Each batch undergoes 12 quality inspection processes to ensure international standards.

How long is the lead time for custom orders?

For custom neodymium magnets, the typical lead time is 10-15 working days. However, urgent orders can be expedited with a minimum 7-day turnaround upon request.

What is the minimum order quantity (MOQ)?

The MOQ for standard neodymium magnets is 100 pieces. For custom products, the MOQ may vary based on complexity but can be negotiated for large-scale projects.

How do you ensure consistent magnetic performance?

We use high-precision sintering and magnetization processes, and every magnet is individually tested for magnetic flux, coercivity, and magnetic energy product before shipment.

Can you provide technical support for magnetic circuit design?

Absolutely. Our team of magnet experts offers free technical consultations, including magnetic simulation and circuit optimization, to help you achieve the best performance.

Do you provide samples for testing?

We offer 3-5 free samples; customers only need to cover the shipping cost. During the sample testing phase, our technical team provides full debugging guidance.

Are your neodymium magnets environmentally friendly?

Yes, our production processes comply with strict environmental standards. All materials are non-toxic, and our waste management system ensures minimal ecological impact.