Circular Samarium Cobalt Magnets

Circular in shape with flat or cylindrical profiles, typically magnetized axially (poles on opposing flat surfaces) or radially (poles on the circumference). Great heat resistance (up to 350°C) and corrosion resistance, stable magnetic performance in extreme environments. 2mm to 150mm diameter, 1mm to 50mm thick.

- Aerospace: Actuators in jet engines, satellite attitude control systems.

- Medical Devices: Implantable magnetic components (e.g., deep-brain stimulation devices).

- High-Tech Sensors: Thermal imaging equipment and high-temperature proximity sensors.

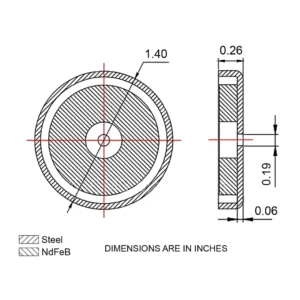

Annular Samarium Cobalt Magnets

Hollow ring-shaped magnets with radial or axial magnetization, to create uniform circular magnetic fields. Central bore for shafts, wires, or optical components. High energy products and stability in harsh conditions, for compact high-performance magnetic circuits.

- Industrial Robotics: Rotor magnets in servo motors for robotic arms.

- Scientific Instruments: NMR spectrometers and particle accelerators.

- Renewable Energy: High-efficiency generators in concentrated solar power systems.

Square Samarium Cobalt Magnets

Rectangular or cubic in shape, with magnetic poles on opposing flat surfaces. Strong directional magnetic fields and robust mechanical stability. Used in assemblies where stacked or arrayed to increase magnetic flux density.

- Heavy Machinery: Magnetic chucks in CNC milling machines.

- Defense Systems: Guidance systems in missiles and military-grade sensors.

- High-Temperature Motors: Turbine generators in geothermal power plants.

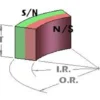

Special-Shape Samarium Cobalt Magnets

Non-standard shapes (e.g., arc-shaped, stepped, perforated, multi-part composites) to meet specific design requirements. Machined by precision grinding or EDM (electrical discharge machining) for complex magnetic field distribution or space-constrained applications.

- Aviation: Curved magnets for aircraft engine ignition systems.

- Optoelectronics: Magnetic lenses in laser beam steering mechanisms.

- Advanced Motors: Multi-pole rotor segments for high-speed electric vehicles.

Support customization options—smco magnets

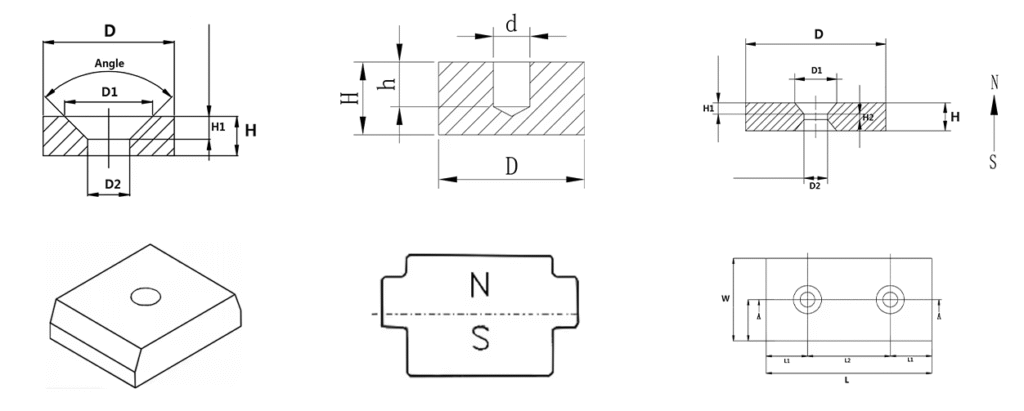

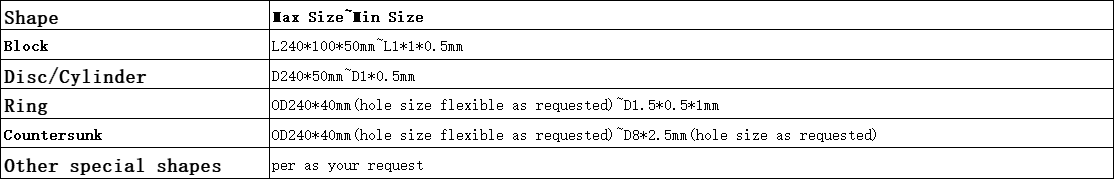

1.Shape and size

Standard shapes: round, square, ring, strip, horseshoe-shaped etc.

Irregular shapes: Processed into non-regular shapes such as fan-shaped, trapezoidal, concave, perforated/slotted, stepped shapes according to drawings.

2.Dimensional accuracy

Customizable parameters such as diameter/side length, thickness, aperture, and curvature are available, with an accuracy of ±0.01mm (requiring precise processing techniques).

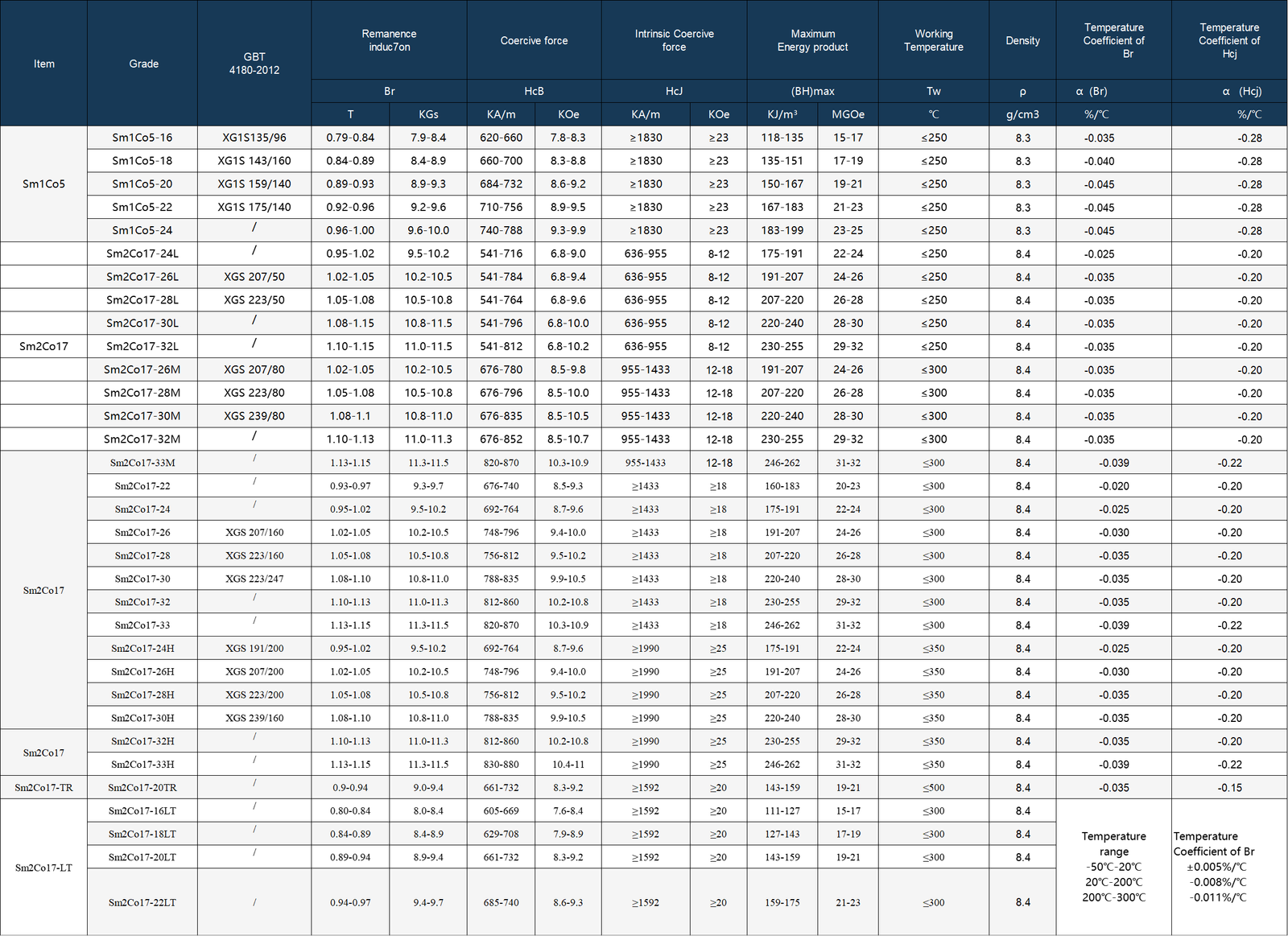

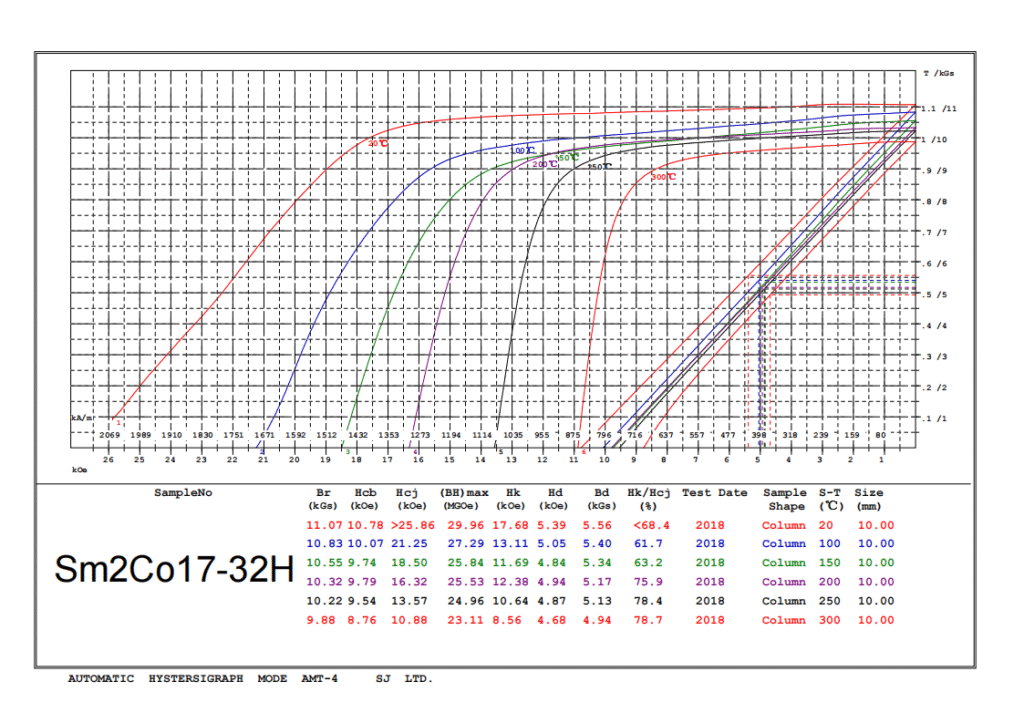

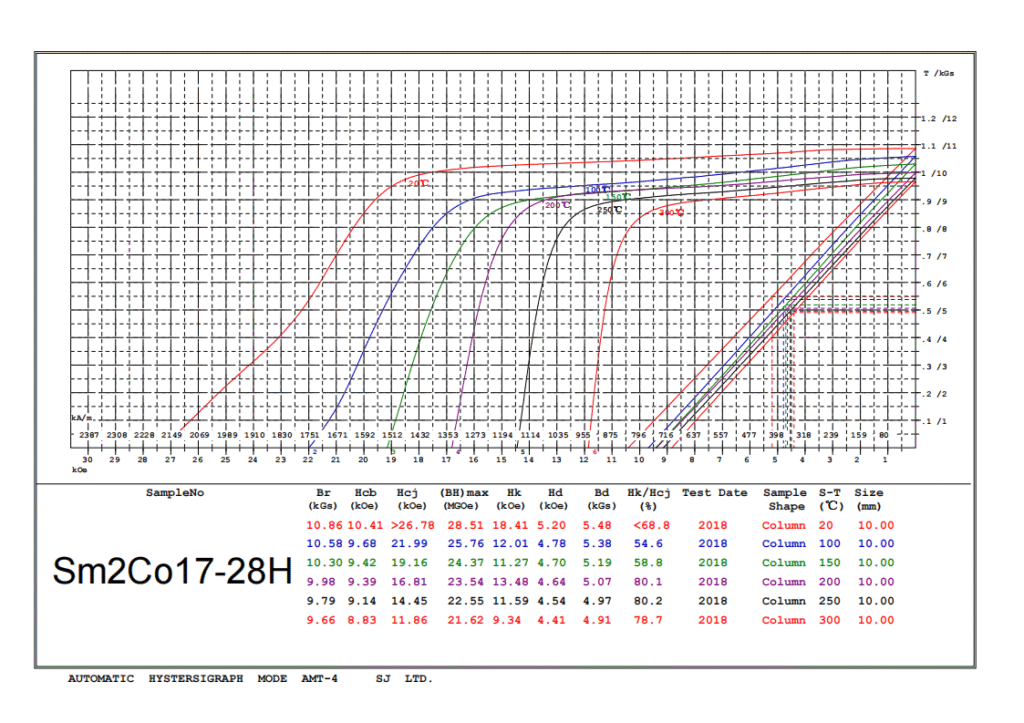

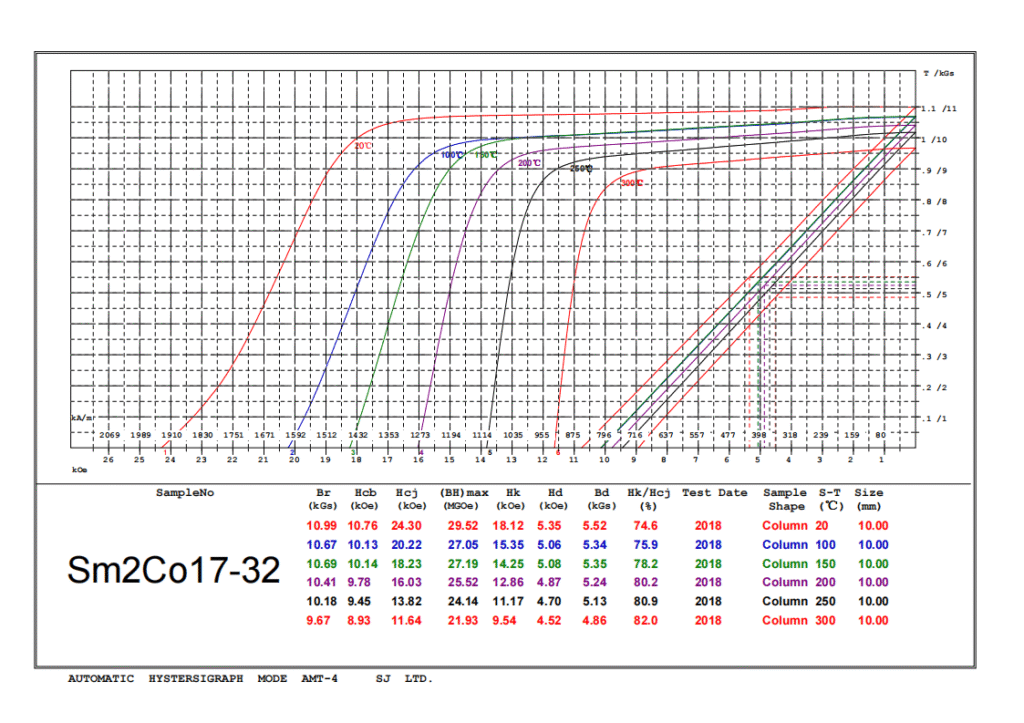

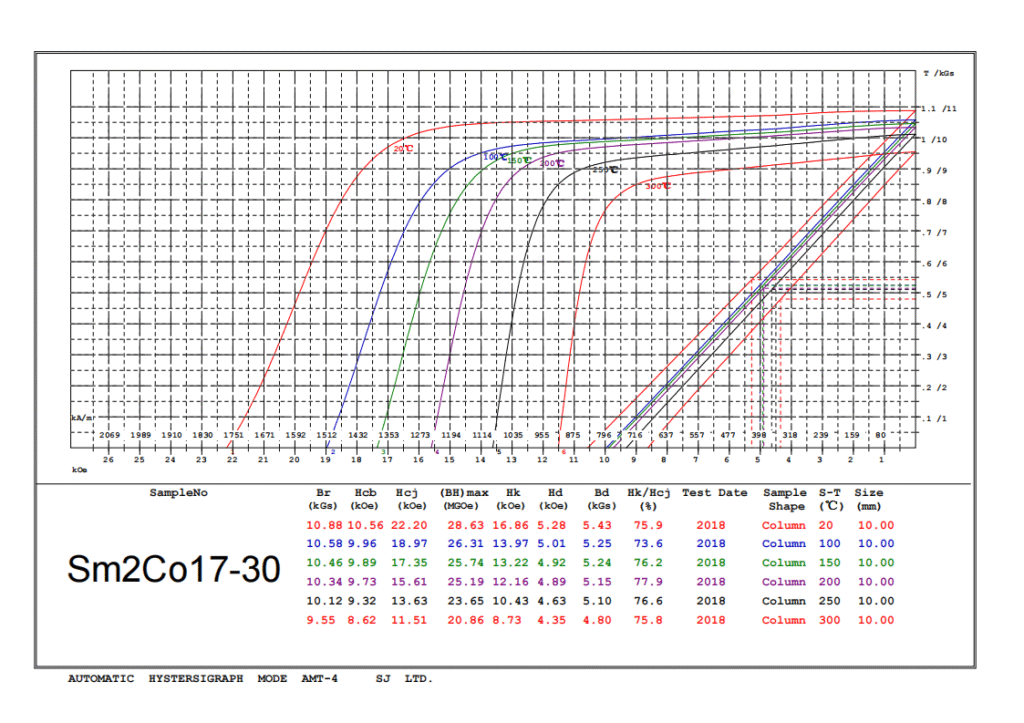

3. Material grade

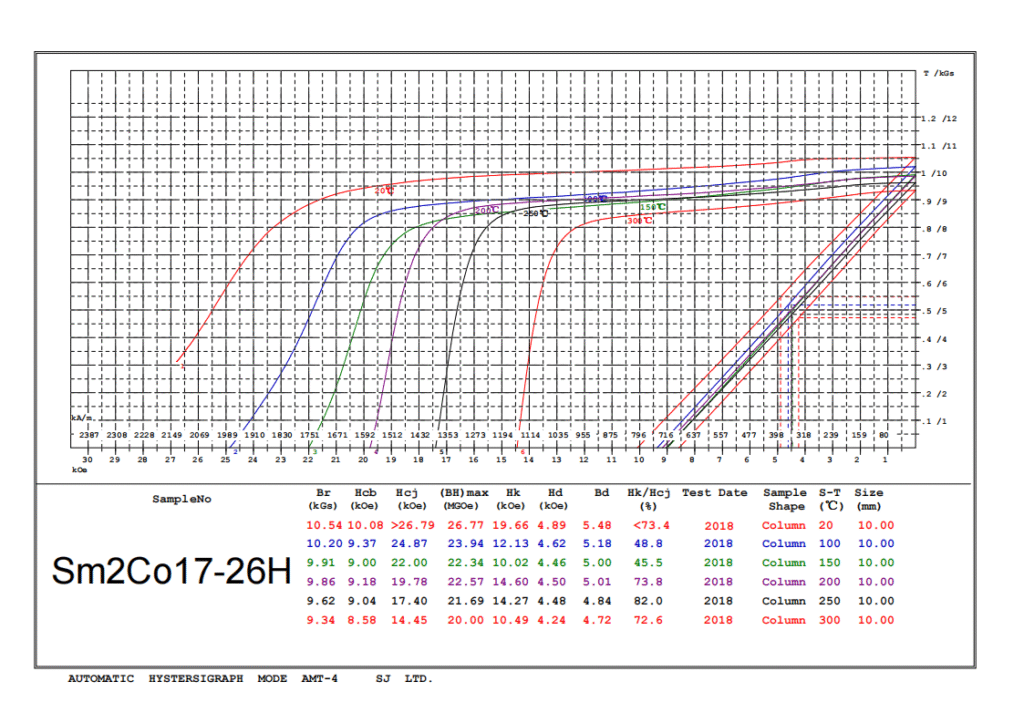

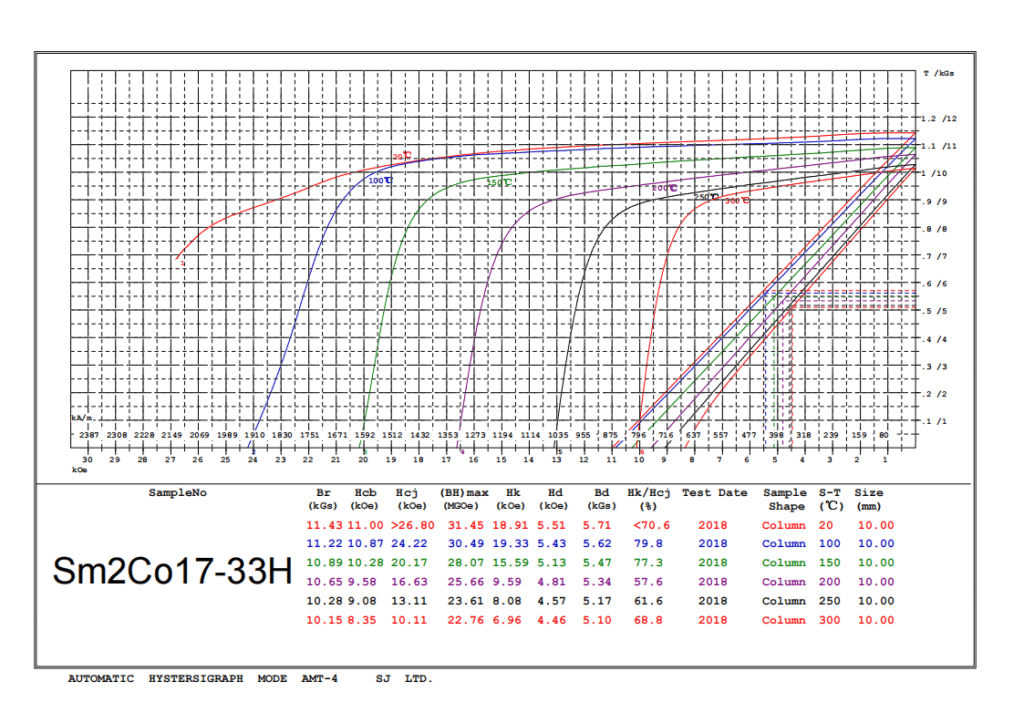

- SmCo5 (Samarium Cobalt type 5) : Magnetic energy product (BHmax) 16-24 MGOe, temperature resistance up to 250℃, suitable for medium-intensity magnetic field requirements.

- Sm2Co17 (Samarium Cobalt 17 type) : Magnetic energy product 24-32 MGOe, temperature resistance up to 350℃, stronger anti-demagnetization ability, suitable for high-temperature and strong magnetic field environments.

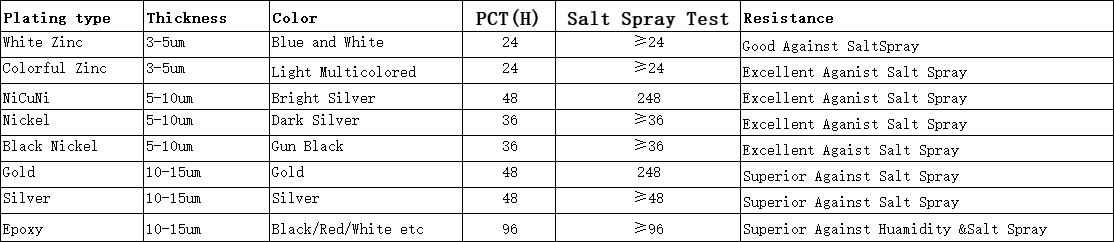

4. Coating process

Coating process

Corrosion-resistant coating: nickel (Ni) plating, gold (Au) plating, platinum (Pt) plating, with a thickness ranging from 5μm to 25μm.

Magnetic body for Marine environment (platinum-plated + epoxy resin encapsulated, no corrosion after 1000 hours of salt spray test).

Insulation treatment: Coated with polytetrafluoroethylene (PTFE) or ceramic coating, with insulation resistance > 100MΩ.

Scene: Magnets for high-voltage electrical equipment (to prevent arc breakdown).

Mechanical protection

Metal packaging: Stainless steel shell welded and sealed, suitable for vibration (50g acceleration) and shock (500g peak) scenarios.

Magnetic components of missile guidance system (stainless steel + damping glue encapsulation)

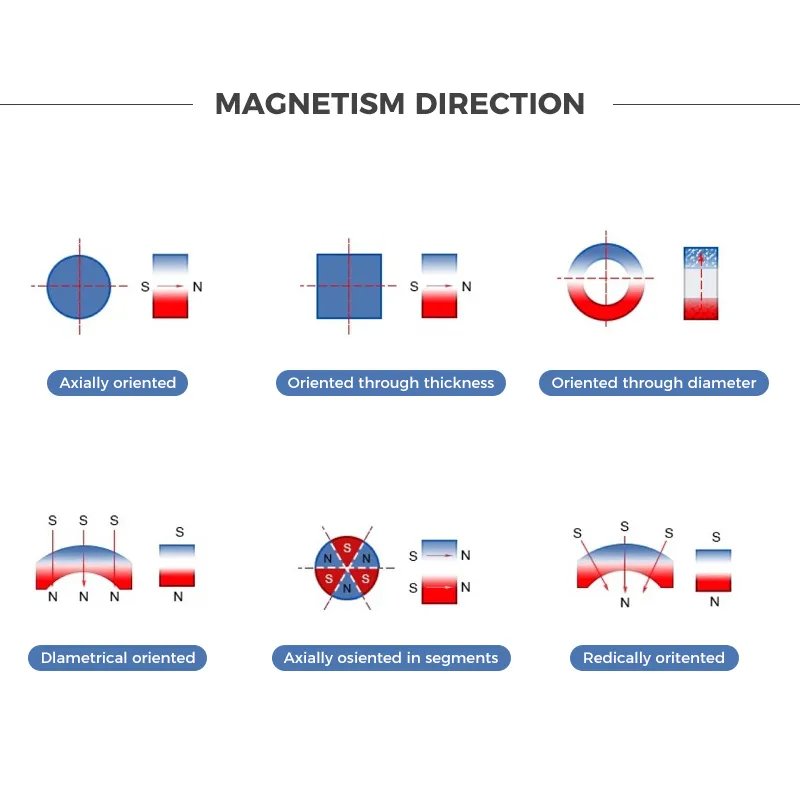

5. Magnetization direction and magnetic field distribution

- Axial magnetization: The magnetic field lines are perpendicular to the plane (for example, the upper and lower surfaces of a circular magnet are the magnetic poles).

- Radial magnetization: The magnetic field lines are along the radius direction (for example, the inner and outer diameters of a ring-shaped magnet are the magnetic poles).

- Multi-pole magnetization: Multiple N/S poles are distributed on the surface of the magnet (such as sine wave magnetization of sector magnets used in motors).

- Magnetization in any direction: According to design requirements, customize the magnetization Angle in non-standard directions.

6. Customized magnetic properties and tolerances

Magnetic energy product (BHmax) : The range of magnetic force intensity can be specified (such as ≥35MGOe).

Tolerance control

Dimensional tolerance: such as diameter ±0.05mm, thickness ±0.02mm.

Magnetic performance tolerance: such as the control of the fluctuation range of residual magnetism (Br) and coercive force (Hcb).

Magnet parameter comparison table

Order Now | Get a Bulk Quote

Frequently Asked Questions—smco Magnets

How resistant are your samarium cobalt magnets to corrosion?

With a dense microstructure and optional advanced coatings (such as Ni-Cu-Ni or epoxy), these magnets offer excellent resistance to oxidation, salt spray, and chemical corrosion, suitable for marine, medical, and outdoor environments.

Can you provide customized shapes and sizes for samarium cobalt magnets?

Yes, we offer full customization for shape (arc, ring, segment), size, magnetization direction, and surface treatment. Our engineers can tailor products to meet your specific application requirements, with dimensional tolerances as precise as ±0.01mm.

What quality certifications do your samarium cobalt magnets have?

All products comply with ISO 9001 quality management standards, RoHS environmental regulations, and REACH requirements. Each batch undergoes 12 strict tests, including magnetic flux measurement, coercivity testing, and dimensional inspection.

What is the minimum order quantity (MOQ) for samarium cobalt magnets?

The MOQ for standard samarium cobalt magnets is 100 pieces. For customized products, the MOQ may vary based on complexity, but we can accommodate smaller trial orders for new projects.

How long does it take to deliver custom samarium cobalt magnet orders?

Custom orders typically have a lead time of 10 working days. For standard products in stock, we can arrange shipment within 5 working days, supported by our efficient production and logistics system.

Are your samarium cobalt magnets cost-effective for large-scale projects?

Despite their high-performance features, our samarium cobalt magnets offer competitive pricing. We provide volume discounts of up to 20% for bulk orders, helping you optimize costs while maintaining quality.