The definition of Samarium Cobalt SmCo Magnets

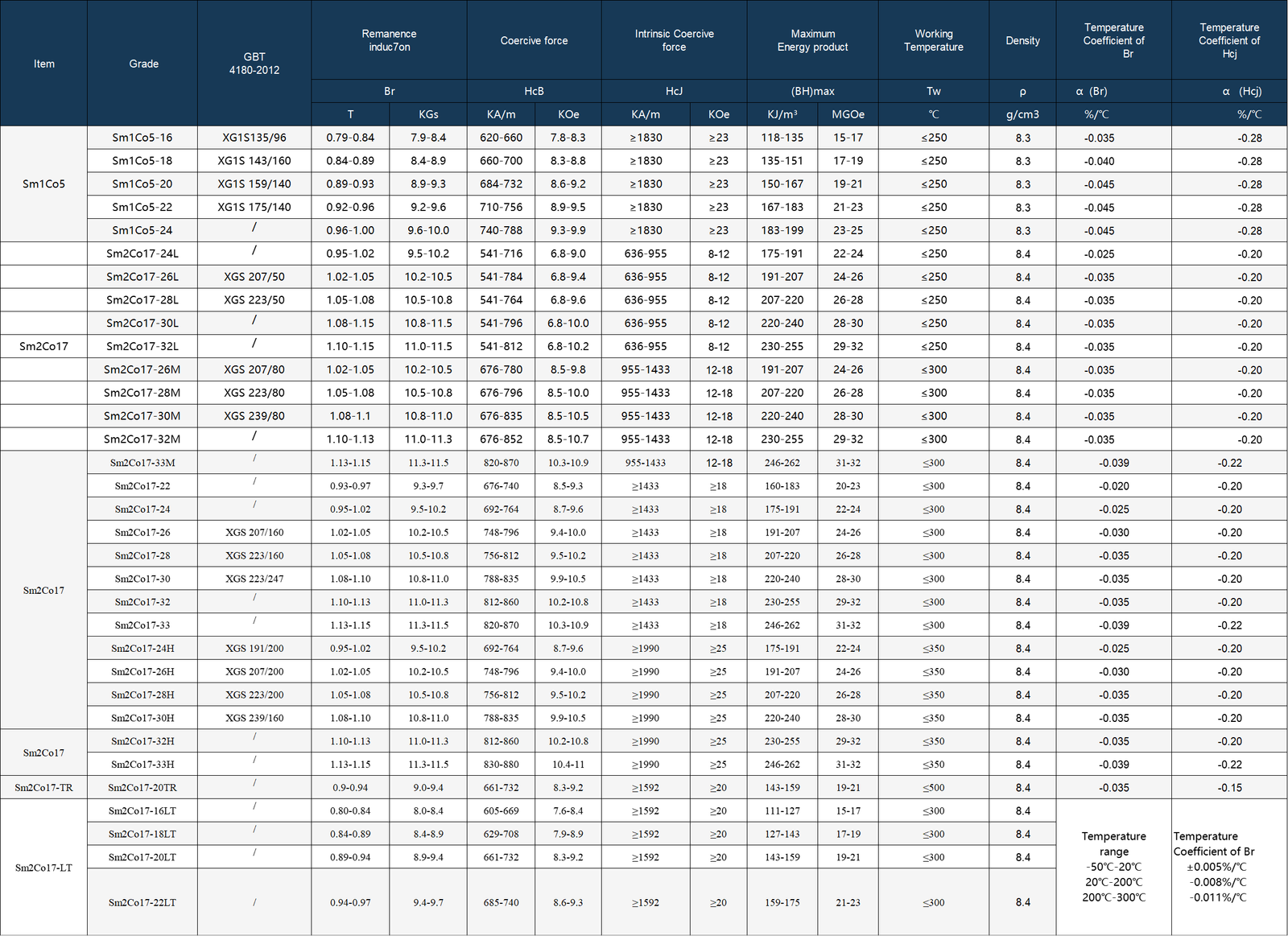

As the second generation of rare earth permanent magnets, samarium cobalt (SmCo) magnets are made of metal samarium (Sm), cobalt (Co), copper (Cu), iron (Fe), zirconium (Zr), and other elements. Classified by structure, they are 1:5 type (SmCo5) and 2:17 type (Sm2Co17), known for their excellent magnetic properties. They have high magnetic energy products (up to 35 MGOe), ultra-low temperature coefficient (-0.008%/℃: 20–200℃), and a maximum working temperature of 350℃. Above 180℃, their magnetic energy product, coercivity, temperature stability, and chemical resistance are better than NdFeB permanent magnet materials.

Samarium Cobalt SmCo Magnets Composition:

- SmCo5: Sm, Co and partial Pr.

- Sm2Co17: Sm, Co, Cu, Fe, Zr.

- Manufacturing Process: Smelting, crushing, pressing, sintering and aging treatment.

Features of Samarium Cobalt SmCo Magnets

- High Magnetic Energy Product: 16–32 MGOe (theoretical limit: 34 MGOe).

- Super High Temperature Resistance: Up to 350℃, better than NdFeB above 180℃.

- Corrosion Resistance: Naturally resistant to corrosion and oxidation, often no need for electroplating.

- Brittleness: Suitable for non-impact applications due to their fragile nature.

- Aerospace: Generators, pump couplings, sensors.

- Military: Magnetic transmission devices and microwave components.