Description

Order Now | Get a Bulk Quote

SmCo Magnets Product Overview

CORT’s Customizable High-Performance SmCo Magnets – Key magnetic components that meet diverse needs. Samarium-cobalt (SmCo) magnets, as a type of high-performance permanent magnetic material, play an important role in many fields due to their excellent magnetic properties, good thermal stability, and corrosion resistance.

SmCo Magnets Core Materials and Characteristics

- Material Composition: Mainly samarium – cobalt (SmCo). Samarium-cobalt is an alloy permanent magnetic material composed of samarium and cobalt. High magnetic energy product, high coercivity, and good temperature stability can maintain stable magnetic properties within a wide temperature range.

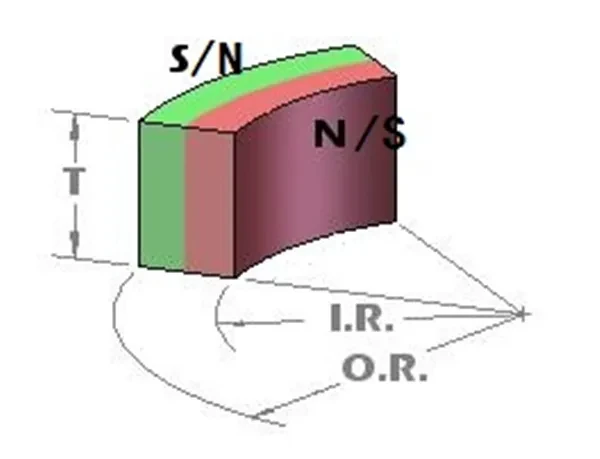

- Shape Feature: Arc. Arc shape design can fit some devices or components with an arc shape structure, such as a motor magnetic circuit and a speaker spatial layout. So it can optimize magnetic field distribution and improve equipment performance.

- Customization Feature: Customizable. Can be adjusted in size, magnetic performance, etc., according to customer requirements. Whether it’s precise requirements for size parameters like arc length, arc height, thickness, inner diameter ,and outer diameter or special requirements for magnetic performance indicators like magnetic energy product and coercivity, we can meet all through our customization service.

SmCo Magnets Application Scenarios

- Electronics Field: In electronic products, used in components that require high magnetic field stability and strength are used, such as precision sensors and small-scale motors. Stable magnetic properties can improve signal accuracy and operational stability of electronic products.

- Speaker Field: As a speaker magnet, it can generate a strong and uniform magnetic field. Interact with the voice coil, which can convert an electrical signal into a sound signal, greatly improving the sound quality and audio effect of speakers. Used in various audio equipment.

- Industrial Field: In industrial automation equipment, used in magnetic fixtures and magnetic separators. Magnetic fixtures can firmly hold workpieces with their strong magnetic force, ensuring machining accuracy. Magnetic separators rely on their magnetic field to separate ferromagnetic impurities from materials, ensuring the smooth production process. In motors and solenoids, SmCo magnets provide a stable and strong magnetic field for energy conversion and mechanical movement control.

- Other: In bags and Apple iPad packs, used in magnetic snaps and other components. Magnetism can open and close conveniently and has some anti-theft and fixing functions.

Customization and wholesale advantages are where our SmCo arc-shaped magnets truly shine. You can tailor every aspect of the magnet to suit your needs: arc length, arc height, thickness, inner diameter, and outer diameter. That means you can fit the magnet to your installation space and usage requirements with ease.

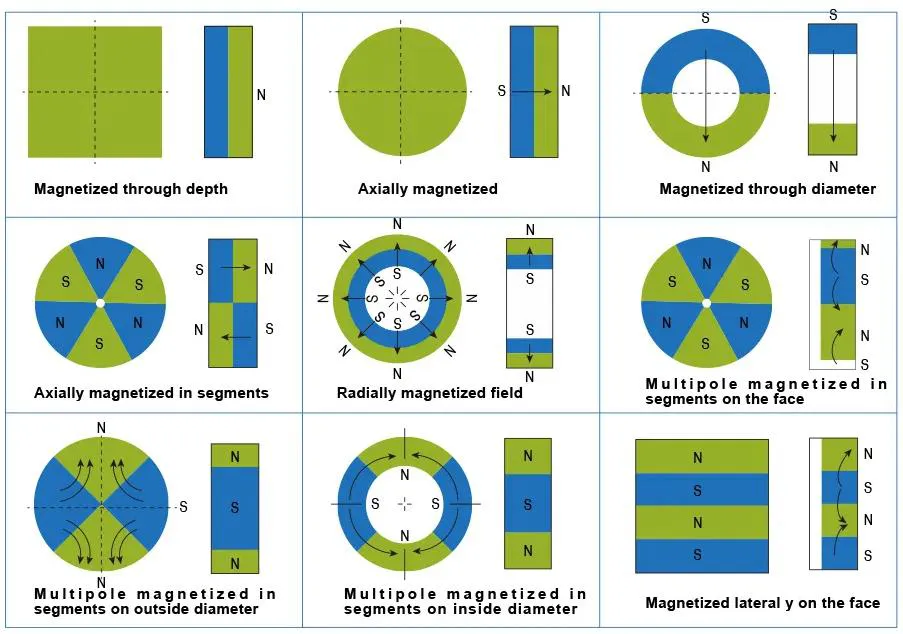

Magnetic performance is where we can really make a difference. We can adjust the magnet’s field strength, direction, and uniformity to meet your specific application needs. For example, in motor applications, we can customize the magnetic energy product and coercivity to boost efficiency and performance. In sensor applications, we can fine-tune the magnetic field direction and uniformity to enhance sensitivity and accuracy.

Our wholesale advantages start with our production capabilities. With the latest equipment and efficient processes in place, we can meet large batch orders quickly and reliably. That means you get the goods you need when you need them.

We also keep costs down for you. By optimizing raw material procurement, streamlining production, and boosting efficiency, we pass the savings on to you. That means you can control your procurement costs while still getting the quality you expect.

Quality is our top priority. We have a strict quality control system in place, monitoring every step from raw material inspection to finished product testing. That means every SmCo arc-shaped magnet meets the standards and customer requirements you demand.

When it comes to installation, we recommend you handle the magnets carefully to avoid damage. Place them according to the design requirements of your equipment to get the best magnetic effect. If you have any questions, we’re here to help.

For maintenance, keep the magnet surface clean and avoid corrosive substances. Regularly check the magnetic strength and appearance. If there’s a problem, contact us. When you’re not using the magnet for a long time, store it in a dry, cool place with minimal magnetic interference.

SmCo Magnets Summary of Product Features

- Great Performance: SmCo material has high magnetic energy product, high coercivity, and good thermal stability. It can keep stable and strong magnetic properties in complex environments and meet the magnetic requirements of different application scenarios.

- Customizable: Comprehensive customization services can meet different customers’ personalized needs in size, magnetic performance, etc., and provide precise magnetic solutions for different applications.

- Widely Used: Used in electronics, speakers, industry, and bags, etc, it plays a key role in improving equipment performance and ensuring the equipment’s normal operation with broad market application.

- Reliable: Strict quality control and professional production process ensure product quality stability and reliability, you can buy with confidence.

Frequently Asked Questions—SmCo Magnets

1. What’s the production lead time for customized products?

The production lead time for customized products usually depends on the complexity of customization and the current production schedule. Generally, for regular customization, the production lead time is 10-15 working days. For special customization, it may take 15-20 working days. We will confirm the specific delivery time with you after you place an order.

2. How can we ensure the magnetic performance of customized magnet meet the requirements?

During customization, we use professional magnetic performance testing equipment to test and debug the magnet multiple times. Before production, our technical team will communicate with you fully to understand your specific magnetic performance requirements and make a production plan accordingly. During production, we will follow the standard process strictly to ensure the magnetic performance meets the standard. Before the product leaves the factory, we will do a final magnetic performance test and only ship the products that meet the requirements.

3. Are there any discount for bulk purchase?

Yes, we have a discount for bulk purchases. The discount range depends on the purchase quantity and product customization. You can contact our salesteam and tell us your purchasing needs, and we will give you a detailed quotation and discount plan.

4. What should I do if there is quality problem with the product during use?

What should I do if there is a quality problem with the product during use?**A: If you have any quality problem with the product during use, please contact our after-sales service as soon as possible and provide us with a detailed description of the problem and relevant photos, and other materials. We will process it as soon as possible. If it’s confirmed to be a product quality problem, we will offer repair, replacement, or refund according to our after-sales service.