Description

Order Now | Get a Bulk Quote

SmCo Rod Magnets Product Overview

CORT’s High-Performance SmCo Rod Magnets – High-quality magnetic components for various applications. Samarium-cobalt (SmCo) was the first rare-earth permanent magnet material to achieve commercial viability and is widely used in many fields with high-performance requirements due to its excellent properties.

SmCo Rod Magnets Core Materials and Characteristics

- Material Composition: Mainly Sm2Co17, samarium-cobalt alloy. Samarium-cobalt materials are made up of samarium, cobalt, and other rare earth elements, with excellent thermal stability, high magnetic performance, good corrosion resistance, and high resistance to demagnetization.

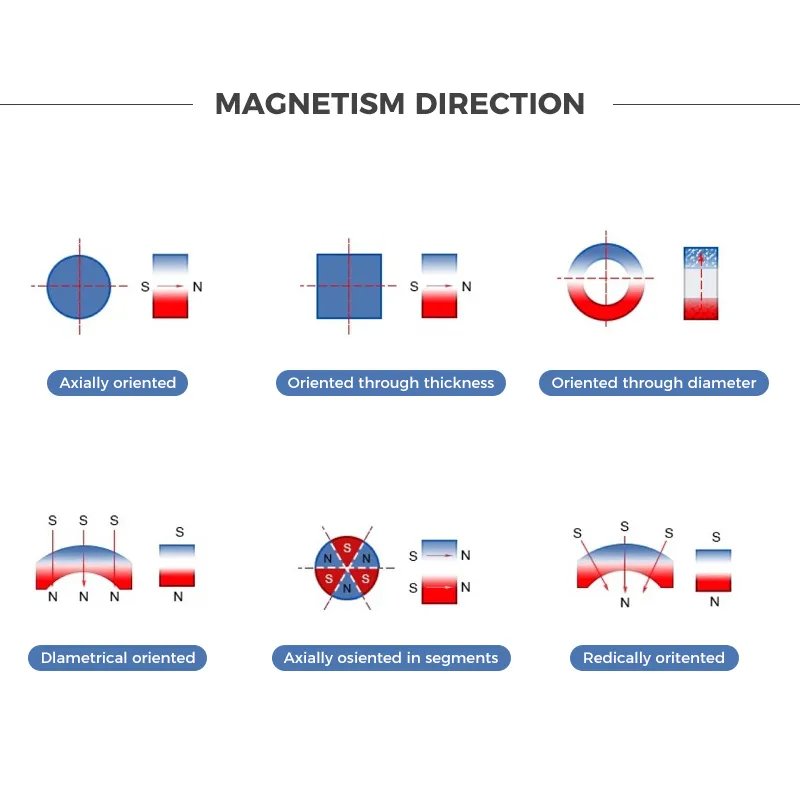

- Shape: Bar. This shape gives the magnet a unique magnetic field distribution, suitable for some application scenarios with specific requirements for the direction and distribution of the magnetic field. For example, in the design of some motors and sensors, the bar shape can better meet the requirements of the magnetic circuit design.

- Size: Customizable. According to the customer’s specific requirements, the length, diameter, and other dimensional parameters of the bar magnet can be adjusted to fit the installation space and usage requirements of different devices.

- Coating: No coating (None) by default, and the spraying (Spraying) coating option is available. In most cases, the inherent corrosion resistance of SmCo is sufficient. But in some special environments, such as high humidity, strong acid or alkali, a spraying coating can further enhance the protection of the magnet and extend its lifespan.

SmCo Rod Magnets Development History and Advantages

SmCo was developed in the 1960s. As a new material, its energy product was three times of other materials at that time. Since then, it has become the preferred material for many high-performance applications. It can maintain stable magnetic properties within a wide temperature range and can work at 350 °C (depending on the grade and permeance coefficient). The change of its flux density with temperature is small. Besides, SmCo has high coercivity and is not easily demagnetized by the external magnetic field.

SmCo Rod Magnets Application Scenarios

- Speaker Field: As speaker magnets, they can generate a stable and strong magnetic field to interact with the voice coil to convert electrical signals into sound signals, to enhance sound quality and audio effect of speakers. They are used in various audio devices.

- Industrial Field: In industrial automation equipment, they can be used in magnetic fixtures to hold workpieces with a strong magnetic force to ensure machining accuracy. They can also be used in magnetic separators to separate ferromagnetic impurities from materials to ensure the normal operation of production lines. In motors and other equipment, they provide a stable and reliable magnetic field for energy conversion and mechanical movement control.

- Other Fields: They are also used in some precision instruments and sensors with high magnetic requirements. Their stable magnetic properties can improve signal accuracy and operational stability.

SmCo Rod Magnets Customization Benefits

- Precise Size Customization: The length and diameter of the bar-shaped magnet can be customized to meet the exact requirements of the customer, to fit the equipment perfectly, and get the best magnetic effect.

- Application-Specific Customization: Based on the different application scenarios of magnetic-field strength, direction, and other magnetic properties, combined with the structure of the bar-shaped magnet, targeted magnetic-performance optimization solutions are provided to meet the needs of various complex applications.

SmCo Rod Magnets Installation and Maintenance

- Installation: Be careful during installation to avoid collision between the magnet and other hard objects, to prevent damage to the magnet or surface scratches. Place the bar-shaped magnet according to the design requirements of the equipment to get the correct magnetic-field direction for the best magnetic effect. If you have any installation questions, please contact us at any time.

- Maintenance: In daily use, keep the surface of the magnet clean and avoid contact with strong acids, alkalis, and other corrosive substances. For magnets with sprayed coating, check the coating regularly. If the coating is damaged, please contact us in time. When not in use for a long time, store the magnet in a dry, cool place away from strong magnetic-field interference to keep the magnetic properties stable.

SmCo Rod Magnets Product Benefits

- Excellent Performance: High magnetic energy product, high coercivity, and good thermal stability, can maintain stable and strong magnetic properties in various complex environments to meet the magnetic requirements of various applications.

- Flexible Customization: Size customization services are available to meet the specific size requirements of different customers, to provide precise magnetic solutions for various applications.

- Wide Application: Applicable to speakers, industry, and precision instruments, to improve equipment performance and ensure equipment normal operation, with broad market application.

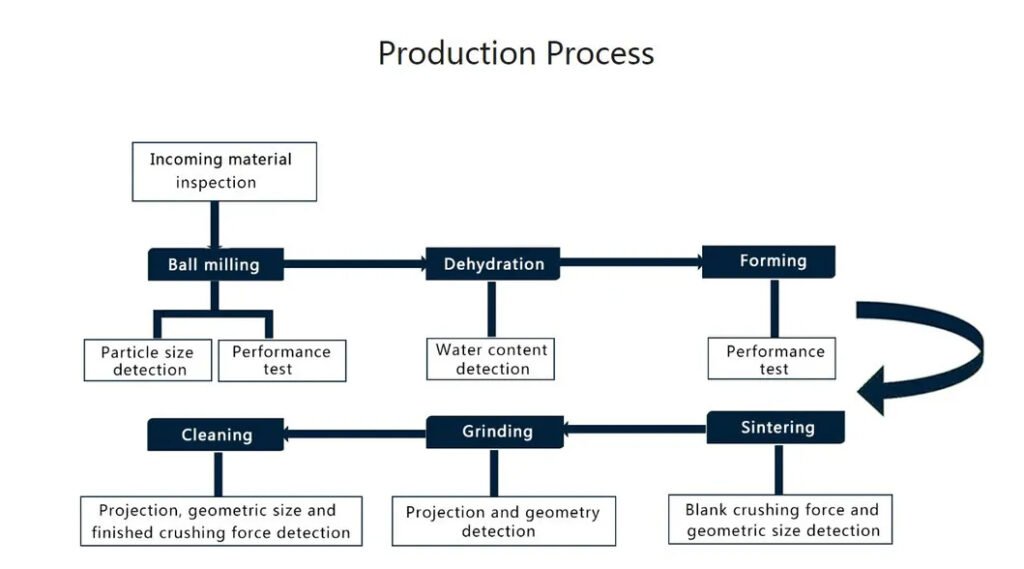

- Reliable Quality: Strict production process and quality control to ensure product quality stability, you can buy with confidence.

Frequently Asked Questions—SmCo Rod Magnets

1. What are the benefits of SmCo rod magnets compared to other SmCo magnets?

The bar-shaped structure of SmCo rod magnets has a unique magnetic field distribution. They are good for applications that require a specific direction and linear magnetic field, such as linear motors or sensors that need a linear magnetic field. Their shape is convenient for use in specific magnetic circuit designs, so you can have more control of the direction and intensity of the magnetic field to meet some special requirements.

2. How long does it take to produce customized sizes?

The production time for customized sizes usually depends on the complexity of the customization and the current production schedule. For regular customization, it’s 10 – 15 working days. For special customization, it may be 15 – 20 working days. We will confirm the delivery time with you after you place the order.

3. How will the magnetic performance of SmCo rod magnets be affected when used in high temperature?

SmCo magnets have good thermal stability and can work normally at 350 °C with a small change in flux density due to temperature. But the specific change of magnetic performance also depends on the magnet grade and permeance coefficient in your application. If you need to use it in high temperatures, please contact us. We can give you a more accurate assessment of the change in magnetic performance and recommend a suitable product for you based on your operating temperature and other conditions.

4. If I use it in corrosive environment, how long will the spraying coating last?

The duration of the spraying coating is affected by many factors, such as the severity of the corrosive environment (pH value, humidity, etc.) and the frequency of use. In a moderately corrosive environment, the sprayed coating can last for several years. But in a highly corrosive environment, more frequent inspection and maintenance of the coating may be required. We will recommend a suitable coating and maintenance plan for you according to your actual use environment to ensure the life of the magnet.